Forklift equipment special for flammable ice on surface of sea floor

A forklift and equipment technology, applied in the field of seabed combustible ice mining equipment, can solve the problems of difficulty in fixing submersible pumps and difficulty in achieving sealing performance, and achieve the effects of small movement range, long maintenance-free time, and reduced mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

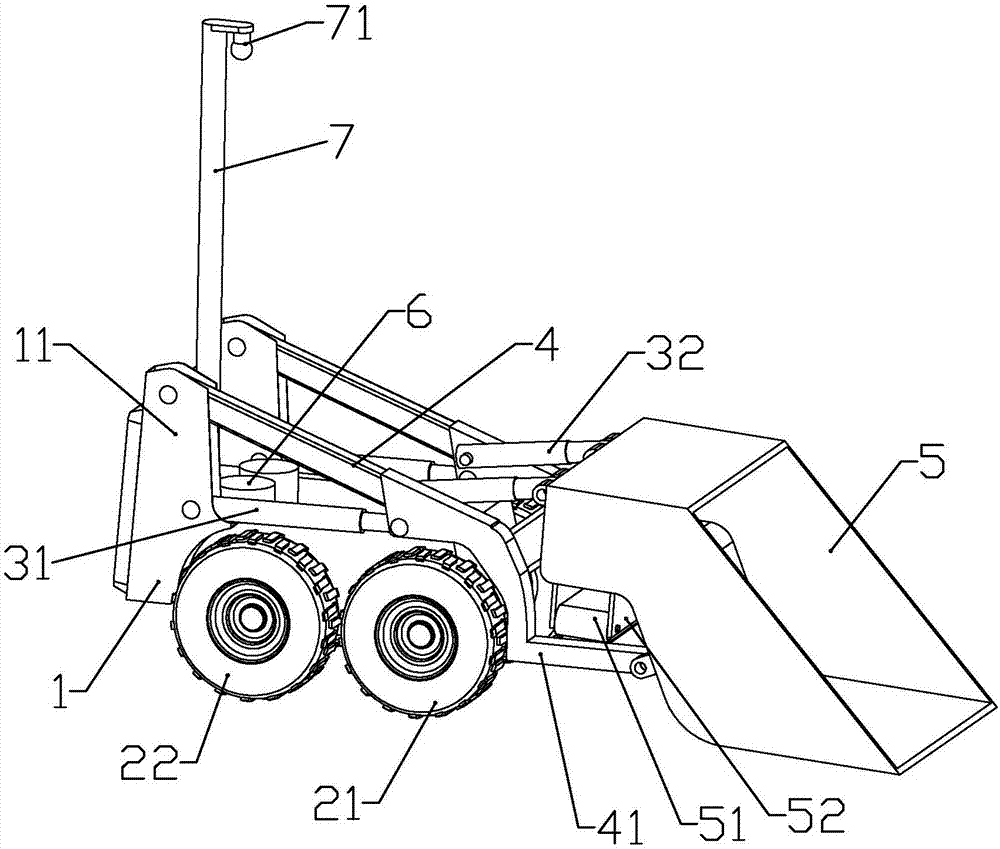

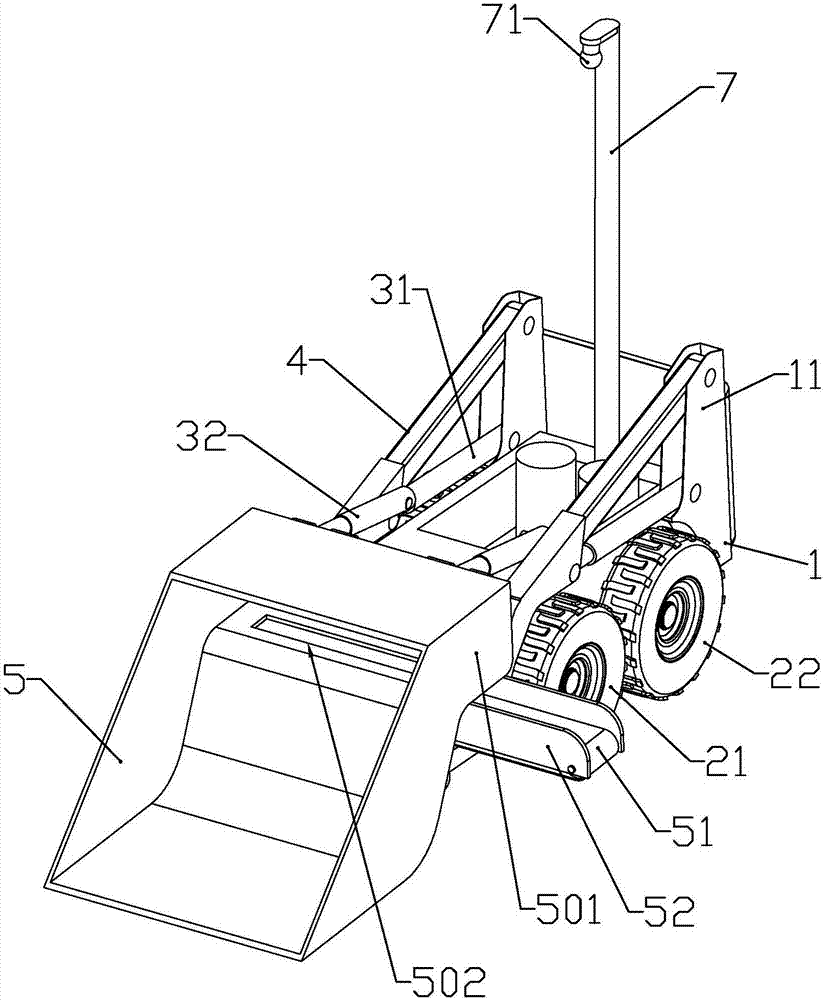

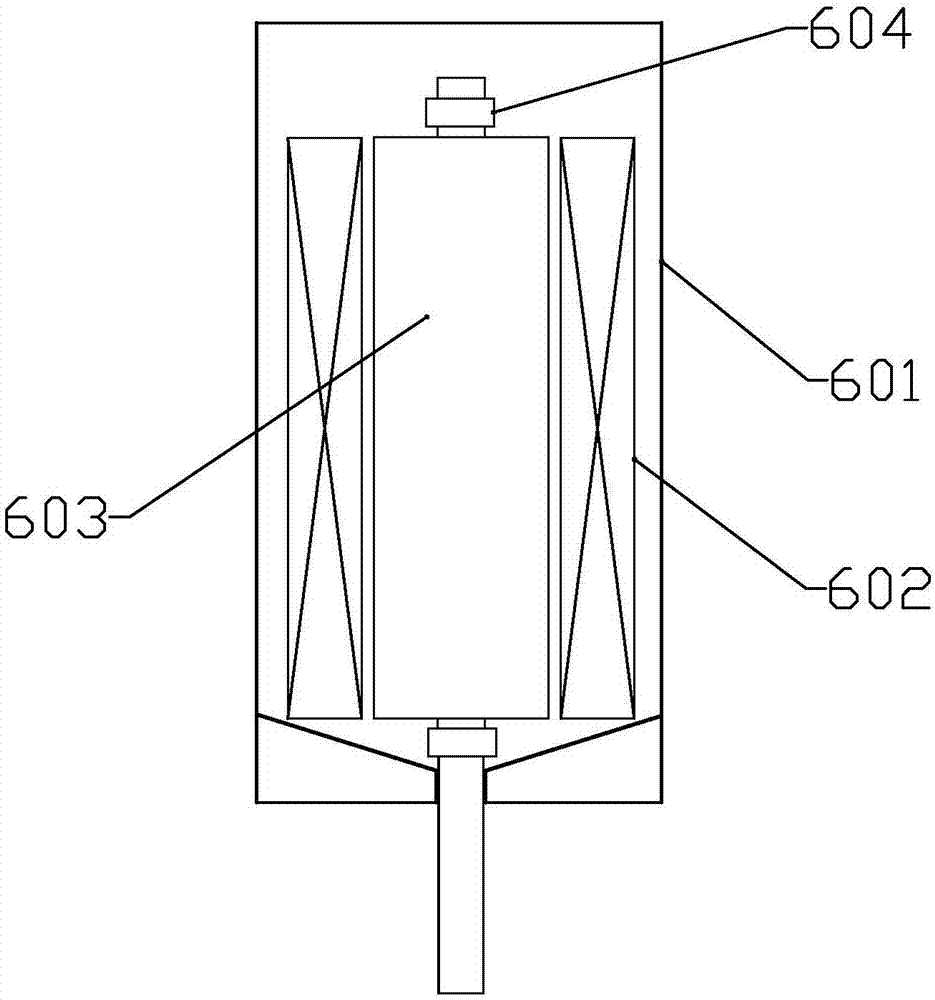

[0048] according to Figure 1 to Figure 3 As shown, this embodiment is a special forklift equipment for combustible ice on the surface of the seabed. It includes a vehicle body 1, two driving wheels 21 rotatably installed on both sides of the front of the vehicle body, and rotatably installed on both sides of the rear of the vehicle body. The two driven wheels 22; the vehicle body is equipped with two drive motors 6 respectively used to drive the two rotating wheels, the drive motor includes a hard non-magnetic metal material housing 601, fixed installation The winding 602 in the housing, and the rotor 603 installed in the housing through the rotor bearing 604 and located on the inner circumference of the winding rotor; the middle of the rotor is the output shaft, the lower end of the output shaft passes through the housing and the output shaft It is connected with the lower end of the shell through a sealed bearing; the lower end of the shell is in the shape of a funnel with a...

Embodiment 2

[0060] Combine Figure 4 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: The drive motor is powered by a power generation device installed on the seabed; the power generation device includes an internal combustion engine 91, and a generator 92 connected to the output shaft of the internal combustion engine The intake end of the internal combustion engine is connected with a mixer 93, which is connected with an oxygen intake pipe and a natural gas intake pipe; the exhaust end of the internal combustion engine is connected with an exhaust pipe, and the other end of the exhaust pipe is connected with a cooling degassing tank 96; The other end of the oxygen gas inlet pipe is connected to an oxygen cylinder, and an air pump a95 is installed at the position of the oxygen gas inlet pipe near the mixer; the natural gas inlet pipe is connected with the gas outlet pipe of the combustible ice extraction well, and the natural gas inlet pipe is close t...

Embodiment 3

[0064] Combine Figure 5 with Image 6 As shown, this embodiment makes the following improvements on the basis of Embodiment 1 or 2: The power generation device and the controller are electrically connected through a suspended power transmission line 8, which includes a cable sheath 81 made of insulating material, An isolation layer is formed in the cable sheath along the length direction. Inside the cable sheath are located on both sides of the isolation layer, respectively, a transmission line cavity 811 and an inflatable cavity 812. The transmission line cavity is pierced with more than two transmission lines 82, so Two electrolytic conductors 84 are pierced in the gas-filled cavity, and the two electrolytic conductors are pierced in the water-absorbing sponge strip 83 used to isolate the two electrolytic conductors. The gas-filled cavity is filled with a weak alkaline solution, such as PH Sodium hydroxide solution with value 8.

[0065] The cable sheath is located in the air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com