Coaxial gas injection valve with floating valve seat and with adjustable circulation section area

A technology of gas injection valve and floating valve seat, which is applied in the direction of engine components, engine control, combustion engine, etc., can solve the problems of error accumulation, injection valve leakage, injection valve difficult to debug, etc., to reduce flow loss and increase flow coefficient , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

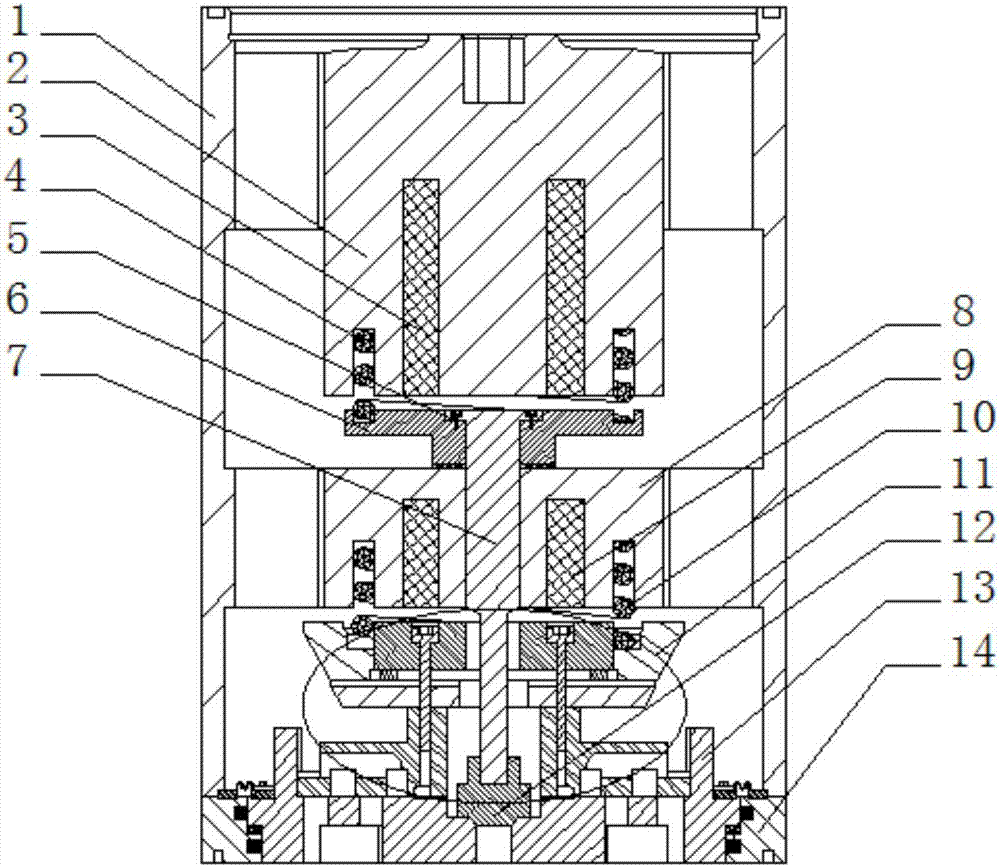

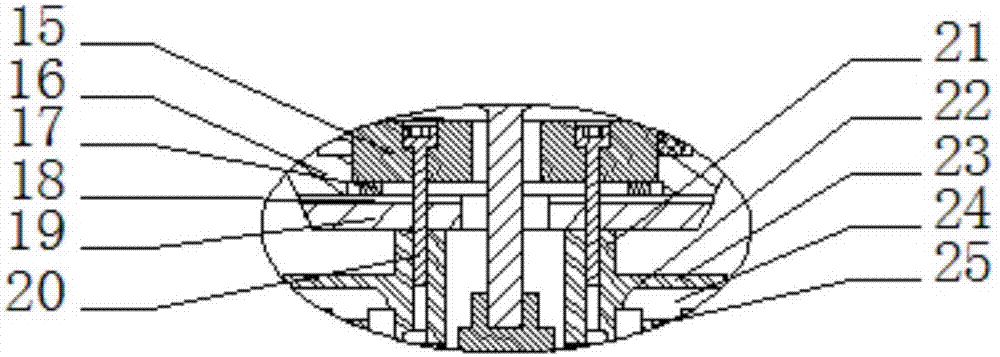

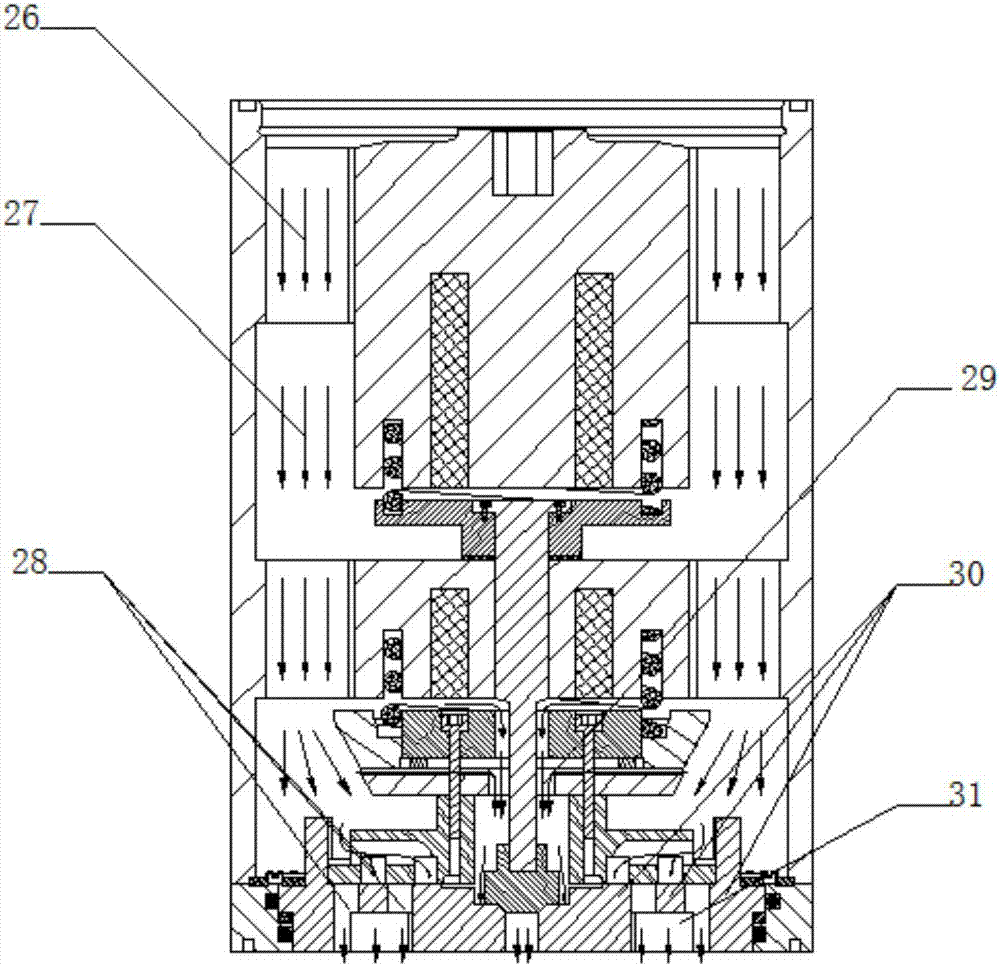

[0019] to combine Figure 1-6 , figure 1 It is a schematic diagram of the overall structure of the coaxial gas injection valve with adjustable flow cross-sectional area with a floating valve seat of the present invention, including a valve body 1, a main electromagnet, a secondary electromagnet, a valve stem 7, a small valve core 12, and a T-shaped armature 6 , spool assembly 11, floating valve seat 14 four parts. The main electromagnet 2 is connected together with the valve body 1 through the upper thread. The main electromagnet mainly consists of an iron core 8 and a coil 9. Both sides of the iron core 8 are provided with annular grooves for arranging the main return spring 10 , and the valve core assembly 11 is arranged under the iron core 8 . The secondary electromagnet is mainly composed of a secondary iron core 2 and a secondary coil 3 . It is character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com