Self-calibration externally bonded ultrasonic liquid level switch measurement system and measurement method thereof

A technology of liquid level switch and measurement system, which is applied in the field of alarm and tank liquid level measurement, can solve the problems of work stability, poor reliability, high misoperation rate of liquid level switch, heavy installation and debugging workload, etc., so as to improve the service life. and stability, small installation and debugging workload, stable and reliable measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

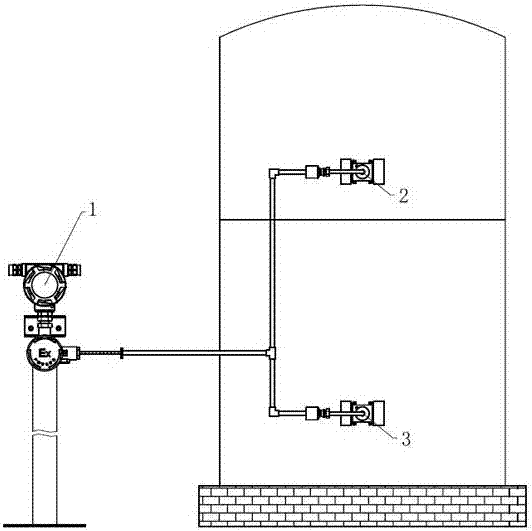

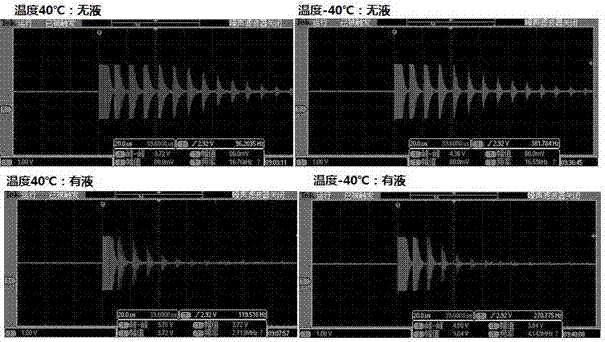

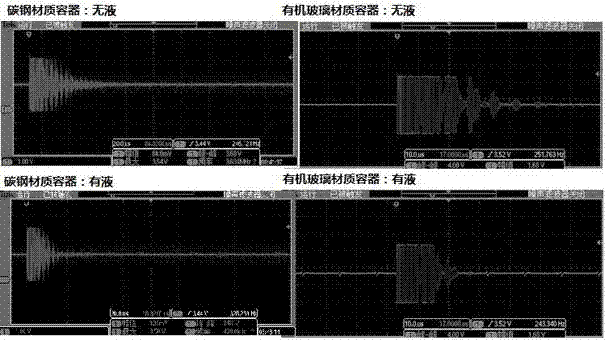

[0031] see Figure 1-7 , a self-calibrating externally attached ultrasonic liquid level switch measurement system, comprising an externally attached ultrasonic liquid level switch host 1, a calibration probe 2, a high-level measuring probe 3 and a low-level measuring probe 4, the calibration probe 2 is installed in a tank where the liquid level cannot When the empty liquid position is reached or outside the liquid position where the liquid level will not be emptied, the high-level measuring probe 3 is installed at the high-level alarm point on the outer upper part of the tank body, and the low-level measuring probe 4 is installed at the low-level alarm point on the outer lower part of the tank body; The calibration probe 2 , the high-level measuring probe 3 and the low-level measuring probe 4 are all connected to the external ultrasonic liquid leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com