Method for measuring purity values and uncertainty degrees of standard substances of phenol and hydroquinone

A technology of hydroquinone and standard substances, which is applied in the field of development of standard substances for detecting the purity of phenolic compounds in freckle-removing cosmetics and shampoos, and can solve problems such as large differences and different test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

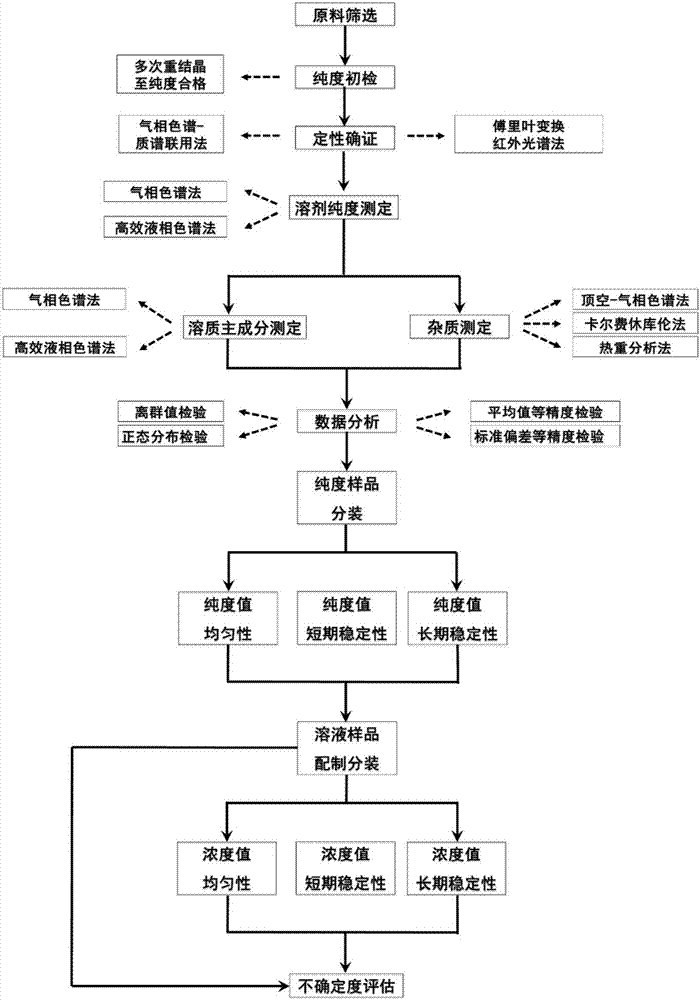

Method used

Image

Examples

Embodiment 1

[0137] Example 1: Phenol

[0138] Step 1 - Raw Material Screening

[0139] The phenol raw material produced by Bailingwei Technology Co., Ltd. was used. Use the HPLC method (see step 3-1.2 of Example 1) to measure the purity value, and obtain the sample to be tested after the initial purity test is qualified after recrystallization twice.

[0140] Step 2 - Qualitative Confirmation

[0141] The phenol was confirmed qualitatively by GC-MS and FT-IR.

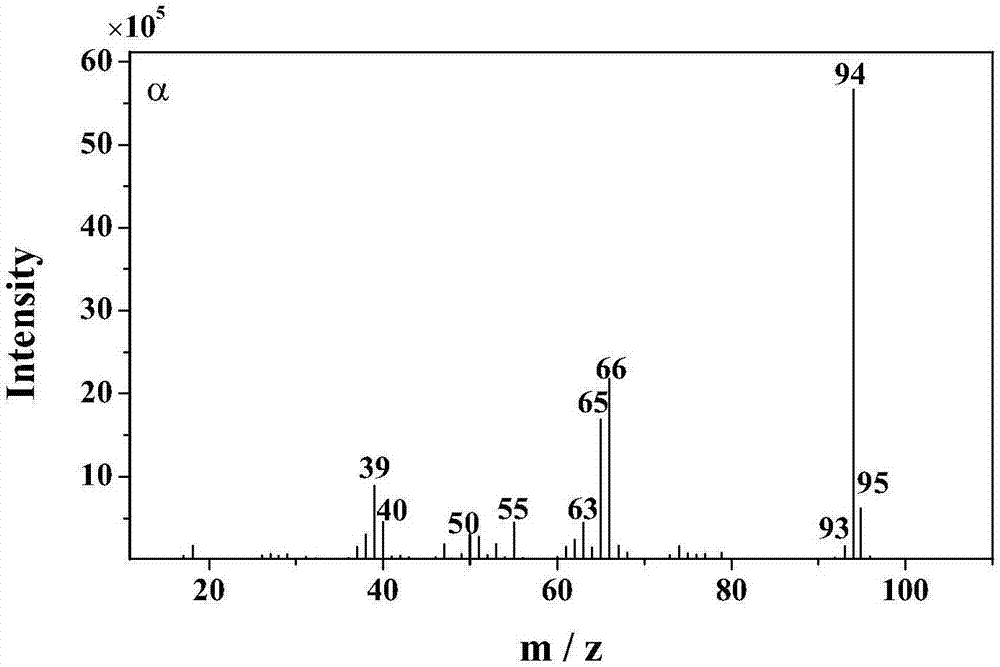

[0142] Step 2-1. Qualitative confirmation of phenol by GC-MS

[0143] For the phenol sample to be tested, it was dissolved in methanol to make a test solution, and the sample was injected for testing. The test conditions are as follows: set the inlet temperature to 250°C, the transfer line temperature to 280°C, the carrier gas flow rate to 1mL / min, the injection volume to 10μL, and the split ratio to 10:1; ℃, keep it for 1min, then raise the temperature to 270℃ at a rate of 15℃ / min, and keep it for 10min.

[0144] attached by...

Embodiment 2

[0209] Embodiment 2: hydroquinone

[0210] Step 1 Raw material screening

[0211] Through the commercially available hydroquinone raw material produced by Bailingwei Technology Co., Ltd. Use the HPLC method (see step 3-1.2 of Example 2) to measure the purity value, and obtain the sample to be tested after the initial purity test is qualified after recrystallization 3 times.

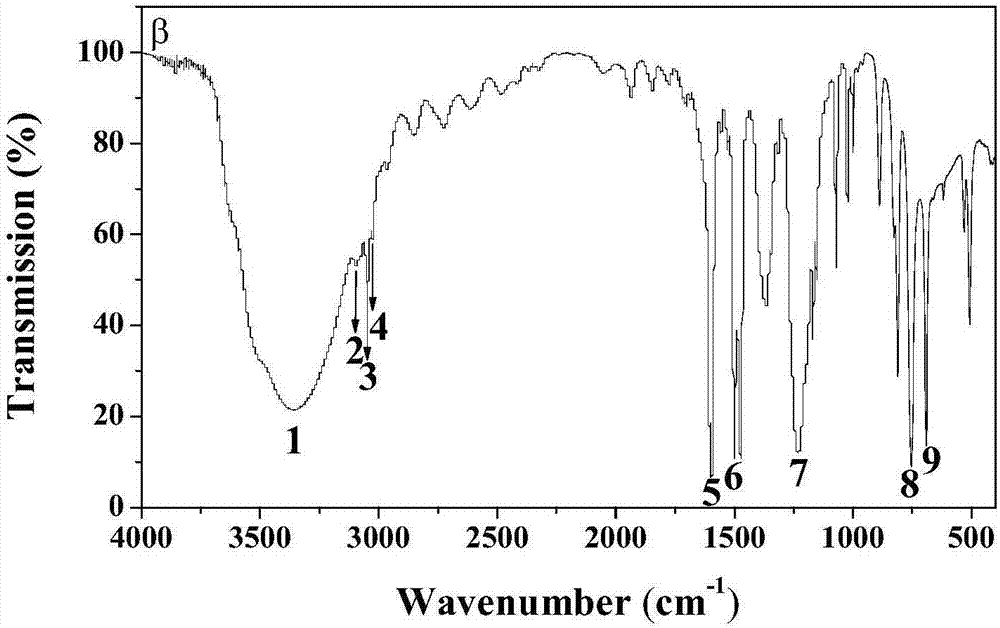

[0212] Step 2 - Qualitative Confirmation

[0213] Using GC-MS method and FT-IR method to qualitatively confirm hydroquinone.

[0214] Step 2-1, Qualitative confirmation of hydroquinone by GC-MS method

[0215] For the test sample of hydroquinone, dissolve it in methanol to make a test solution, and inject it for testing. The test conditions are as follows: set the inlet temperature to 250°C, the transfer line temperature to 280°C, the carrier gas flow rate to 1mL / min, the injection volume to 10μL, and the split ratio to 10:1; the temperature rise operation of the chromatographic column is: It is: use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com