Multiple degree of freedom adjusting system of large aperture reflector

A large-diameter mirror and adjustment system technology, applied in the field of multi-degree-of-freedom adjustment systems, can solve the problems of insufficient precision, difficult to adapt to large-diameter equipment, limited degree of freedom adjustment, etc., to improve work efficiency, reduce size, and reduce size desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

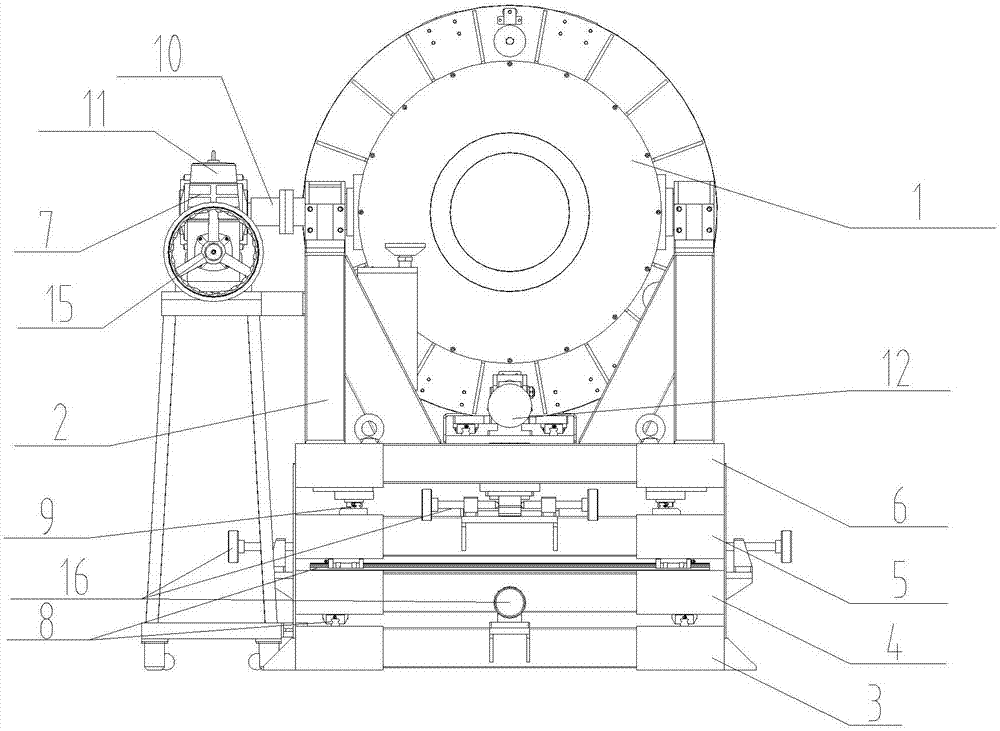

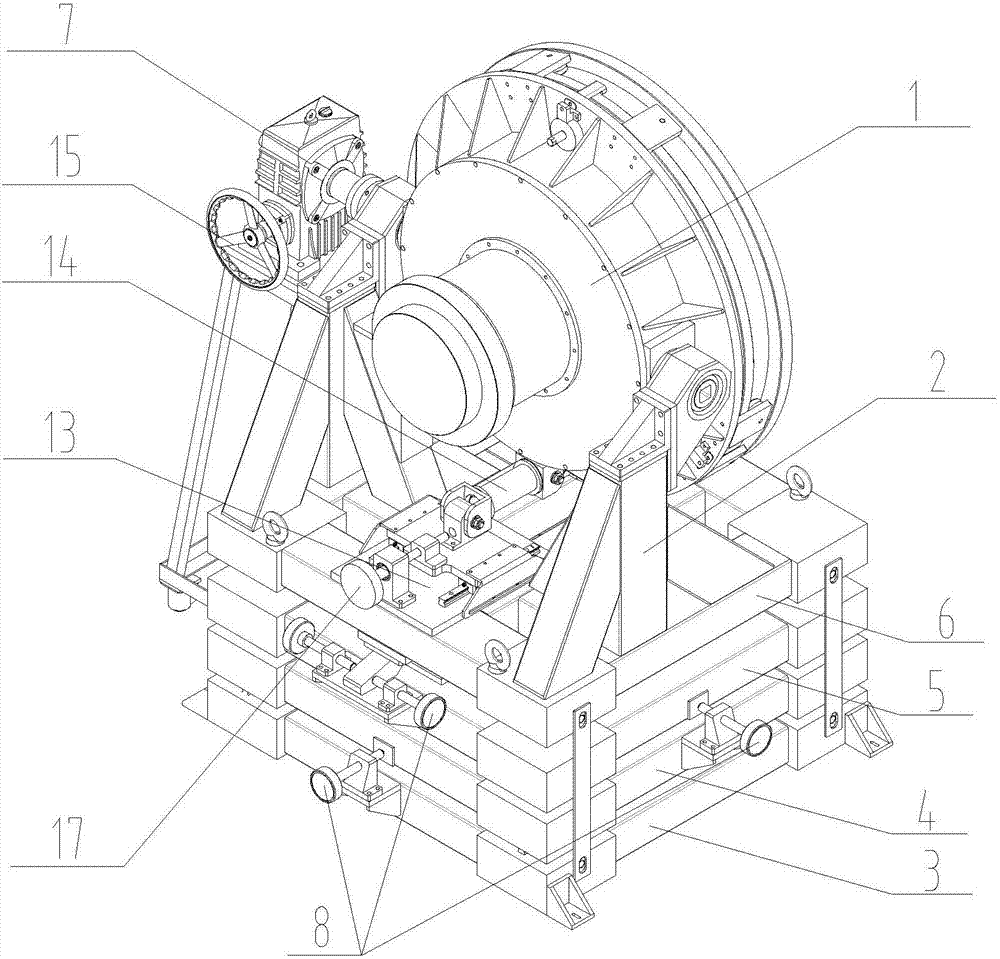

[0022] like Figure 1-Figure 2 As shown, the embodiment provides a multi-degree-of-freedom adjustment system for a large-aperture mirror, including a main mirror chamber 1, a U-shaped support base 2, a base 3, a front and rear translation assembly 4, a left and right translation assembly 5, an azimuth rotation assembly 6 and a pitch Rotate the assembly, the front and rear translation assembly 4 is fixed on the base 3 through the linear guide rail 8, the left and right translation assembly 5 is fixed on the front and rear translation assembly 4 through the linear guide rail 8, and the azimuth rotation assembly 6 is fixed on the left and right translation assembly 5 through the arc guide rail 9, The U-shaped support base 2 is fixed on the azimuth rotation assembly 6, and the main mirror chamber 1 is arranged on the U-shaped support base 2 and is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com