Industrialized bottle-type culturing method of pleurotus ostreatus

A cultivation method and factory-like technology, applied in botany equipment and methods, horticulture, application, etc., can solve the problems of inconsistent product quality, poor fruiting uniformity, low biological efficiency, etc., and achieve biological efficiency improvement, yield The uniformity of the mushrooms is good and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

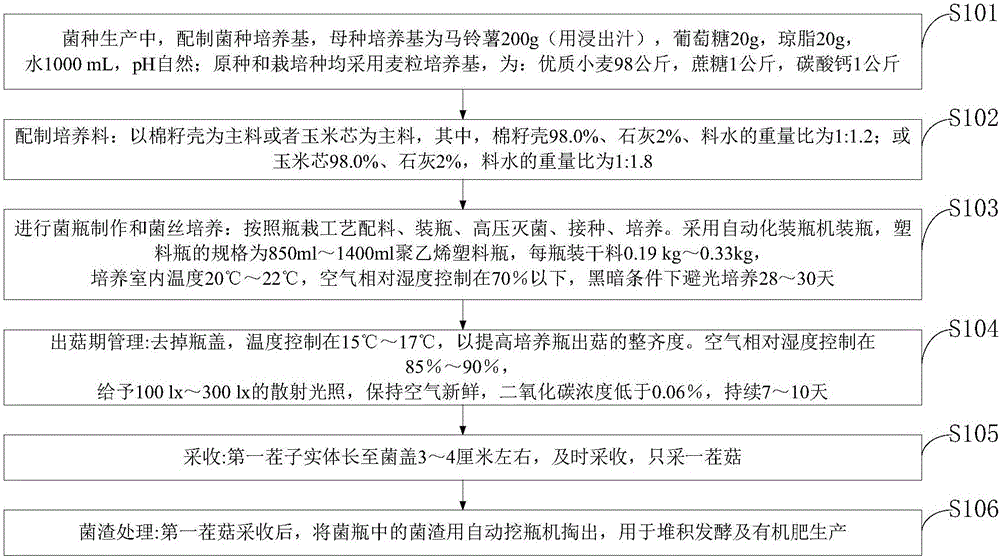

[0031] The industrialized bottle-type cultivation method of Pleurotus ostreatus provided by the embodiment of the present invention comprises the following steps: strain production, compost preparation, bacterial bottle production and hyphae cultivation, mushroom fruiting management, fungal residue treatment,

[0032] Specifically:

[0033] In the production of strains, the strain medium is prepared. The mother seed medium is 200g of potatoes (with leaching juice), 20g of glucose, 20g of agar, 1000mL of water, and natural pH; both the original species and the cultivated species use wheat grain medium, which is: 98 kg of high-quality wheat, 1 kg of sucrose, and 1 kg of calcium carbonate;

[0034] Preparation of compost: Cottonseed hulls or corn cobs as the main material, wherein 98.0% cottonseed hulls, 2% lime, and a weight ratio of 1:1.2 to water; or 98.0% corncobs, 2% lime, and water The weight ratio is 1:1.8;

[0035] Carry out bacterial bottle production and mycelia cultu...

Embodiment 2

[0041] The industrialized bottle-type cultivation method of Pleurotus ostreatus provided by the embodiment of the present invention comprises the following steps: strain production, compost preparation, bacterial bottle production and hyphae cultivation, mushroom fruiting management, fungal residue treatment,

[0042] Specifically:

[0043] In the production of strains, the strain medium is prepared. The mother seed medium is 200g of potatoes (with leaching juice), 20g of glucose, 20g of agar, 1000mL of water, and natural pH; both the original species and the cultivated species use wheat grain medium, which is: 98 kg of high-quality wheat, 1 kg of sucrose, and 1 kg of calcium carbonate;

[0044] Preparation of compost: Cottonseed hulls or corn cobs as the main material, wherein 98.0% cottonseed hulls, 2% lime, and a weight ratio of 1:1.2 to water; or 98.0% corncobs, 2% lime, and water The weight ratio is 1:1.8;

[0045] Carry out bacterial bottle production and mycelia cultu...

Embodiment 3

[0051] The industrialized bottle-type cultivation method of Pleurotus ostreatus provided by the embodiment of the present invention comprises the following steps: strain production, compost preparation, bacterial bottle production and hyphae cultivation, mushroom fruiting management, fungal residue treatment,

[0052] Specifically:

[0053] In the production of strains, the strain medium is prepared. The mother seed medium is 200g of potatoes (with leaching juice), 20g of glucose, 20g of agar, 1000mL of water, and natural pH; both the original species and the cultivated species use wheat grain medium, which is: 98 kg of high-quality wheat, 1 kg of sucrose, and 1 kg of calcium carbonate;

[0054] Preparation of compost: Cottonseed hulls or corn cobs as the main material, wherein 98.0% cottonseed hulls, 2% lime, and a weight ratio of 1:1.2 to water; or 98.0% corncobs, 2% lime, and water The weight ratio is 1:1.8;

[0055] Carry out bacterial bottle production and mycelia cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com