Cultivation method of transgenic oyster mushroom Pofst3 +

A cultivation method and transgenic technology, applied in mushroom cultivation, cultivation, plant cultivation, etc., can solve the problems of poor uniformity of mushroom production, low biological efficiency, late start of factory cultivation of oyster mushrooms, etc., and achieve good uniformity of mushroom production , ensure safety, and improve biological efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

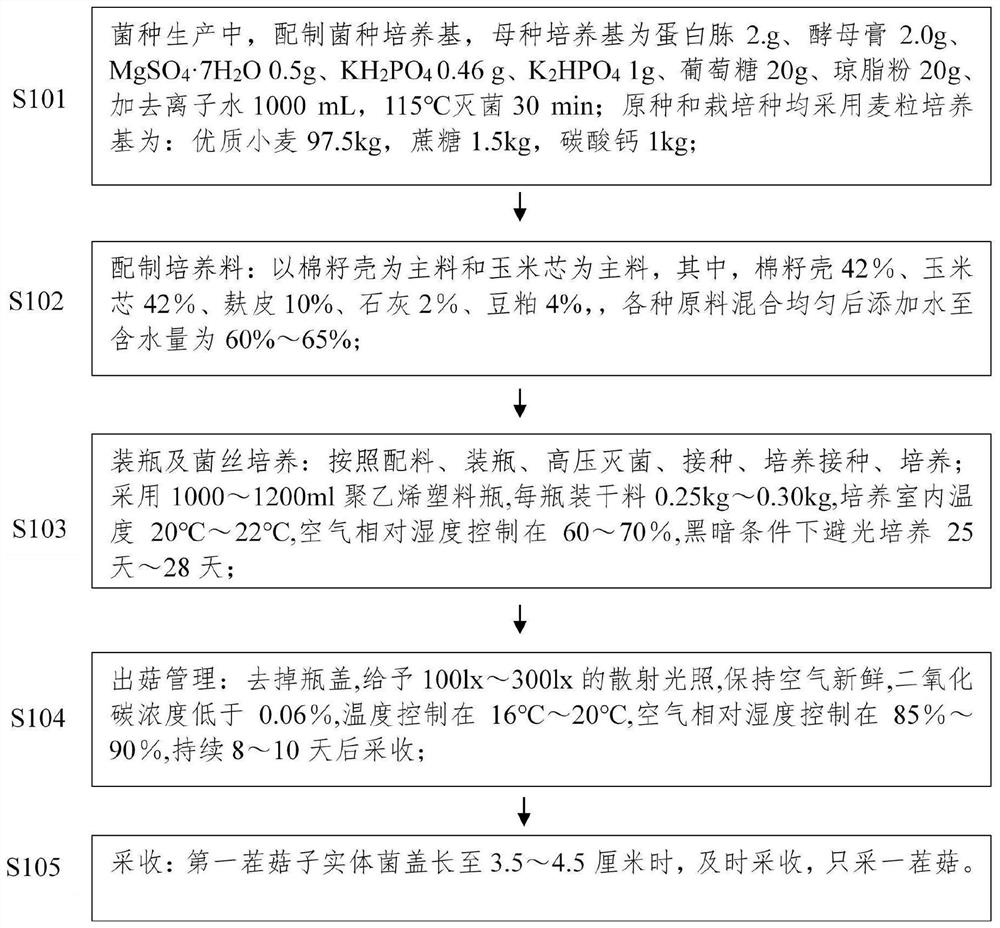

[0023] In this example, transgenic oyster mushroom Pofst3 + The cultivation method includes the following steps:

[0024] S1, prepare a strain medium to obtain a cultivar; Described preparation strain medium: the mother seed medium is peptone 2.0g, yeast extract 2.0g, MgSO 4 ·7H 2 O 0.5g, KH 2 PO 4 0.46g, K 2 HPO 4 1 g, 20 g of glucose and 20 g of agar powder, add 1000 mL of deionized water, and sterilize at a temperature of 115°C for 30 minutes; both the original seed and the cultivar use the wheat grain medium: 98 kg of high-quality wheat, 1 kg of sucrose, and 1 kg of calcium carbonate ;

[0025] The production process of the mother seed: The prepared mother seed medium is divided into test tube slants. After the mother seed medium is solidified, the transgenic oyster mushroom Pofst3 stored in the low-temperature refrigerator is taken out. + The strains were inoculated into test tubes and placed in an incubator for two weeks in the dark at a temperature of 22°C to 24°...

Embodiment 2

[0033] In this example, transgenic oyster mushroom Pofst3 + The cultivation method includes the following steps:

[0034] S1, prepare a strain medium to obtain a cultivar; Described preparation strain medium: the mother seed medium is peptone 2.0g, yeast extract 2.0g, MgSO 4 ·7H 2 O 0.5g, KH 2 PO 4 0.46g, K 2 HPO 4 1 g, 20 g of glucose and 20 g of agar powder, add 1000 mL of deionized water, and sterilize at a temperature of 115°C for 30 minutes; both the original seed and the cultivar use the wheat grain medium: 98 kg of high-quality wheat, 1 kg of sucrose, and 1 kg of calcium carbonate ;

[0035] The production process of the mother seed: The prepared mother seed medium is divided into test tube slants. After the mother seed medium is solidified, the transgenic oyster mushroom Pofst3 stored in the low-temperature refrigerator is taken out. + Bacteria, inoculated in test tubes, placed in an incubator, and cultured for two weeks in the dark at a temperature of 22°C;

...

Embodiment 3

[0043] In this example, transgenic oyster mushroom Pofst3 + The cultivation method includes the following steps:

[0044] S1, prepare a strain medium to obtain a cultivar; Described preparation strain medium: the mother seed medium is peptone 2.0g, yeast extract 2.0g, MgSO 4 ·7H 2 O 0.5g, KH 2 PO 4 0.46g, K 2 HPO 4 1 g, 20 g of glucose and 20 g of agar powder, add 1000 mL of deionized water, and sterilize at a temperature of 115°C for 30 minutes; both the original seed and the cultivar use the wheat grain medium: 98 kg of high-quality wheat, 1 kg of sucrose, and 1 kg of calcium carbonate ;

[0045] The production process of the mother seed: The prepared mother seed medium is divided into test tube slants. After the mother seed medium is solidified, the transgenic oyster mushroom Pofst3 stored in the low-temperature refrigerator is taken out. + Bacteria, inoculated in test tubes, placed in an incubator, and cultured for two weeks in the dark at a temperature of 24°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com