Manufacturing technology for burned chicken and preparation method thereof

A production process and chicken technology, applied in food science and other directions, can solve the problems of inconvenient sales, affect taste, and inconvenient temperature control, and achieve the effect of reducing difficulty, increasing variety, and increasing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A production process of roasted chicken, the raw materials of which are chicken, edible salt, sucrose, cooking wine, cumin powder, shallot powder, edible oil, medlar and ginger, wherein the parts by weight of each raw material are: 150.0 parts of chicken , 15.0 parts of edible salt, 7.5 parts of sucrose, 7.5 parts of cooking wine, 1.5 parts of cumin powder, 1.5 parts of chive powder, 15.0 parts of edible oil, 1.5 parts of medlar, and 3.0 parts of ginger.

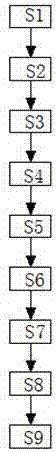

[0024] A preparation method of roasted chicken, comprising the following steps:

[0025] S1) Materials: Take 150.0 parts of chicken, 15.0 parts of edible salt, 7.5 parts of sucrose, 7.5 parts of cooking wine, 1.5 parts of cumin powder, 1.5 parts of shallot powder, 15.0 parts of edible oil, 1.5 parts of medlar and 3.0 parts of ginger.

[0026] S2) Treatment: wash 150.0 parts of chicken with clean water, and grind 1.5 parts of medlar and 3.0 parts of ginger.

[0027] S3) Mixing: Stir and mix 15.0 parts of edible salt, ...

Embodiment 2

[0035] Embodiment 2: a kind of manufacturing process of steamed bun chicken, its raw material adopts chicken, edible salt, sucrose, cooking wine, cumin powder, shallot powder, edible oil, medlar, ginger, aniseed, cinnamon, three Nye, white pepper, Amomum seed and licorice are raw materials, wherein the parts by weight of each raw material are: 200.0 parts of chicken, 20.0 parts of edible salt, 10.0 parts of sucrose, 10.0 parts of cooking wine, 2.0 parts of cumin powder, 2.0 parts of shallot powder, 20.0 parts of edible oil, wolfberry 2.0 parts of ginger, 4.0 parts of ginger, 20.0 parts of aniseed, 4.0 parts of cinnamon, 8.0 parts of three Nye, 4.0 parts of white pepper, 4.0 parts of amomum, and 8.0 parts of licorice.

[0036] A preparation method of roasted chicken, comprising the following steps:

[0037] S1) Materials: Take 200.0 parts of chicken, 20.0 parts of edible salt, 10.0 parts of sucrose, 10.0 parts of cooking wine, 2.0 parts of cumin powder, 2.0 parts of shallot pow...

Embodiment 3

[0047] Embodiment 3: A kind of manufacturing process of steamed bun chicken, its raw material adopts chicken, edible salt, sucrose, cooking wine, cumin powder, shallot powder, edible oil, medlar, ginger, Chinese prickly ash, aniseed, cinnamon, three Nye, tangerine peel , ginger, angelica, Zikou, clove, fennel, woody, amomum and nutmeg, as raw materials, wherein the parts by weight of each raw material are: 250.0 parts of chicken, 25.0 parts of edible salt, 17.5 parts of sucrose, 17.5 parts of cooking wine , 2.5 parts of cumin powder, 2.5 parts of shallot powder, 25.0 parts of edible oil, 2.5 parts of medlar, 5.0 parts of ginger, 25.0 parts of Chinese prickly ash, 25.0 parts of aniseed, 25.0 parts of cinnamon, 10.0 parts of three nai, 10.0 parts of tangerine peel, and ginger 10.0 parts of Angelica dahurica, 10.0 parts of Angelica dahurica, 5.0 parts of Zikou, 5.0 parts of cloves, 10.0 parts of cumin, 5.0 parts of woody incense, 5.0 parts of amomum and 5.0 parts of nutmeg.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com