Filter press with filter plate auxiliary mounting device

An installation device and filter press technology, applied in filtration separation, membrane filter, filtration treatment and other directions, can solve the problems of weak installation and fixation of the machine, fast guide rail wear, poor filtration effect, etc., to reduce the use of equipment and Cost of maintenance, reduced friction, easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

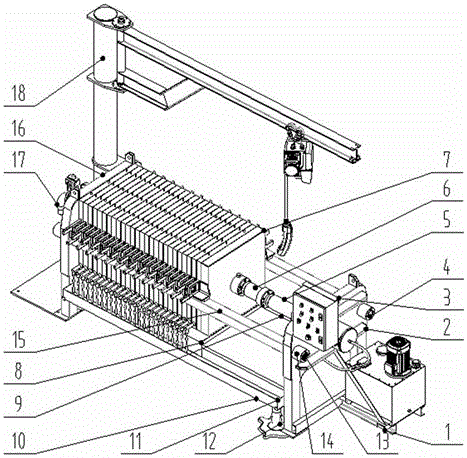

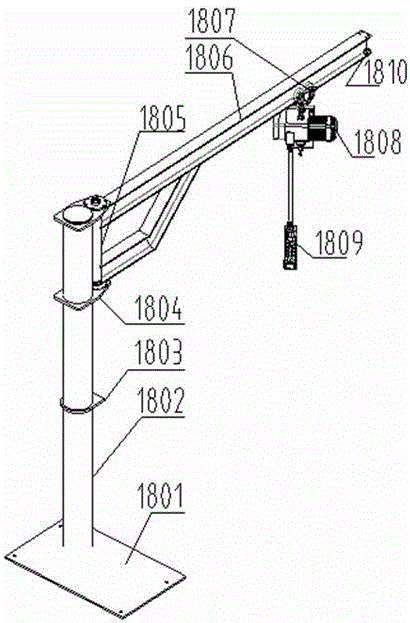

[0031] Such as figure 1 , 2 As shown in , 3, the filter press with auxiliary filter plate installation device includes a hydraulic support seat 1, a left support seat 2, a control box support seat 3, a piston cylinder 4, a piston push rod 5, a connecting shaft 6, a filter plate 7, and a filter cake Collection plate 8, filter cake collection plate support channel steel 9, filtrate collection tank 10, filtrate collection tank support plate 11, filtrate collection tank support base 12, beam 13, shaft sleeve 14, guide rail 15, right support 16, feed pipe 17. Auxiliary lifting device 18, bracket seat 1801, column 1802, column fixing plate 1803, rotary shaft support 1804, rotary shaft 1805, hanging beam 1806, sliding trolley 1807, lifting device 1808, wire control system 1809, limit block 1810 .

[0032] The hydraulic support seat 1 is installed on the left support 2, and it is connected with the left support 2 by means of screw fastening; it is made of channel steel welding.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com