Method and device for conducting silver or silver alloy contact hard soldering through alternating current welding machine

A silver alloy contact and electric welding machine technology, which is applied to electric heating devices, auxiliary devices, welding equipment, etc., can solve problems such as affecting the fluidity and spreadability of solder, inability to braze, and affecting the quality of brazing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

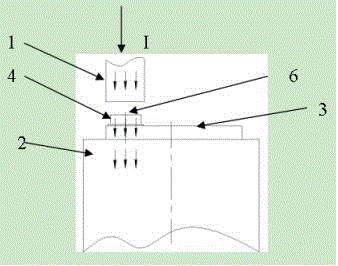

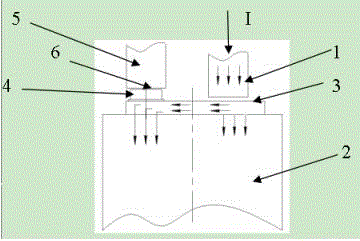

[0018] Example 1. An electric welding machine for brazing silver or silver alloy contacts, such as figure 2 As shown, it includes an upper electrode 1 and a lower electrode 2, and also includes a pressure rod 5, a metal reed 3 is arranged between the upper electrode 1 and the lower electrode 2, and a solder 4 is placed on the metal reed 3, and the solder 4 is placed Below the pressing rod 5, the pressing rod 5 compresses the brazing material 4, and there is a contact point 6 between the brazing material 4 and the pressing rod 5.

[0019] During welding, the metal reed 3 is placed on the lower electrode 2 so that the metal reed 3 is located between the upper electrode 1 and the lower electrode 2 . Put the brazing material 4 on the metal reed 3, press the brazing material 4 and the metal reed 3 tightly with the pressing rod 5, the brazing material 4 and the pressing rod 5 have a contact 6, and then turn on the power to make the upper electrode 1 and the metal reed 3 The metal...

Embodiment 2

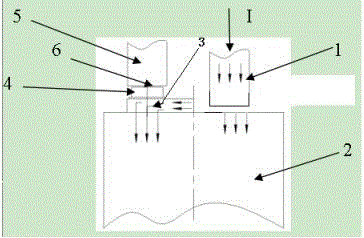

[0020] Embodiment 2. A kind of electric welder carries out the device of silver or silver alloy contact brazing, as image 3 As shown, it includes an upper electrode 1 and a lower electrode 2, and also includes a pressure rod 5, a metal reed 3 is placed on the lower electrode 2, a solder 4 is placed on the metal reed 3, and the solder 4 is placed under the pressure rod 5, and the pressure rod 5 Press the brazing material 4 tightly, and the brazing material 4 has a contact point 6 with the pressure rod 5 .

[0021] When welding: place the metal reed 3 on the lower electrode 2, put the brazing material 4 on the metal reed 3, press the brazing material 4 and the metal reed 3 with the pressure rod 5, and then turn on the power to make the upper electrode 1 and the The lower electrode 2 is connected, and the current flows through the lower electrode 2, so that the lower electrode 2 generates heat, and the heat is conducted to the metal reed 3, the contact 6 and the solder 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com