A brazing method for the end of a slender embedded casing pipe

An embedded, sleeved technology, applied in tubular articles, welding equipment, applications, etc., can solve problems such as the limitation of the amount of solder coating, the inability to guarantee the brazing gap, and the inability to guarantee the need for joint welding, etc. Avoid gap changes, ensure brazing quality, and ensure the effect of brazing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for brazing the end of a slender and embedded casing pipe, which is characterized in that the brazing method for the end of a slender and embedded casing includes the following contents:

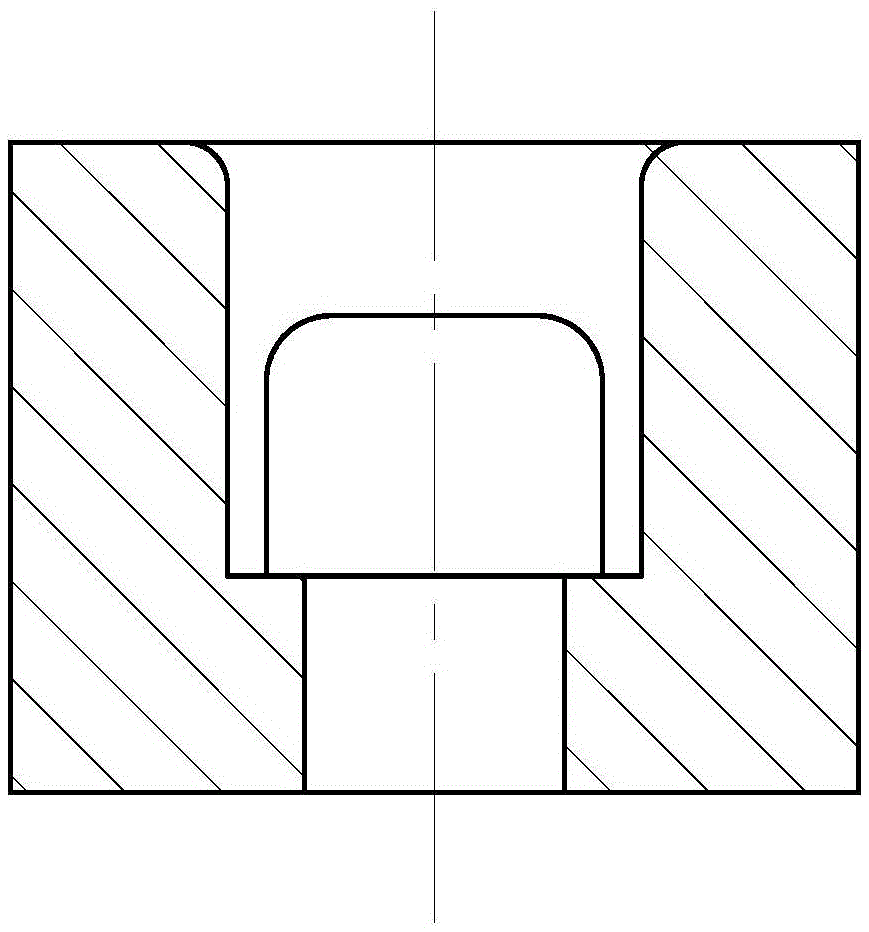

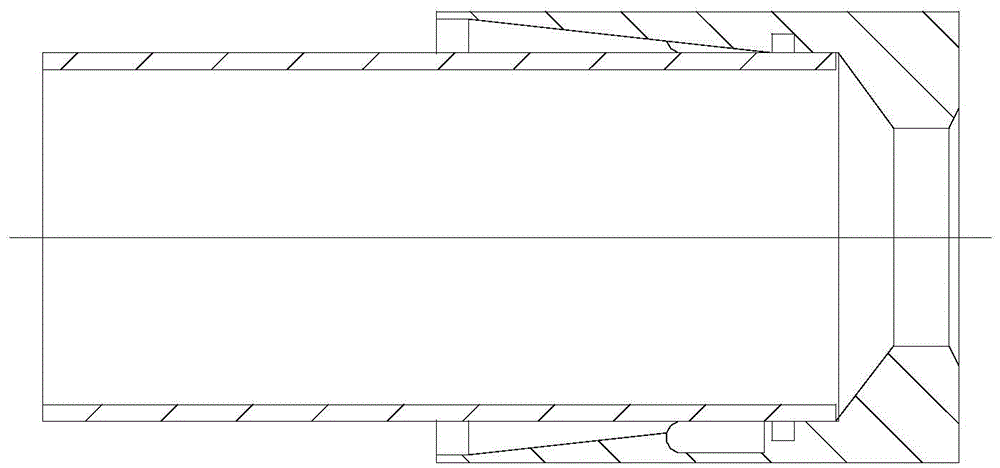

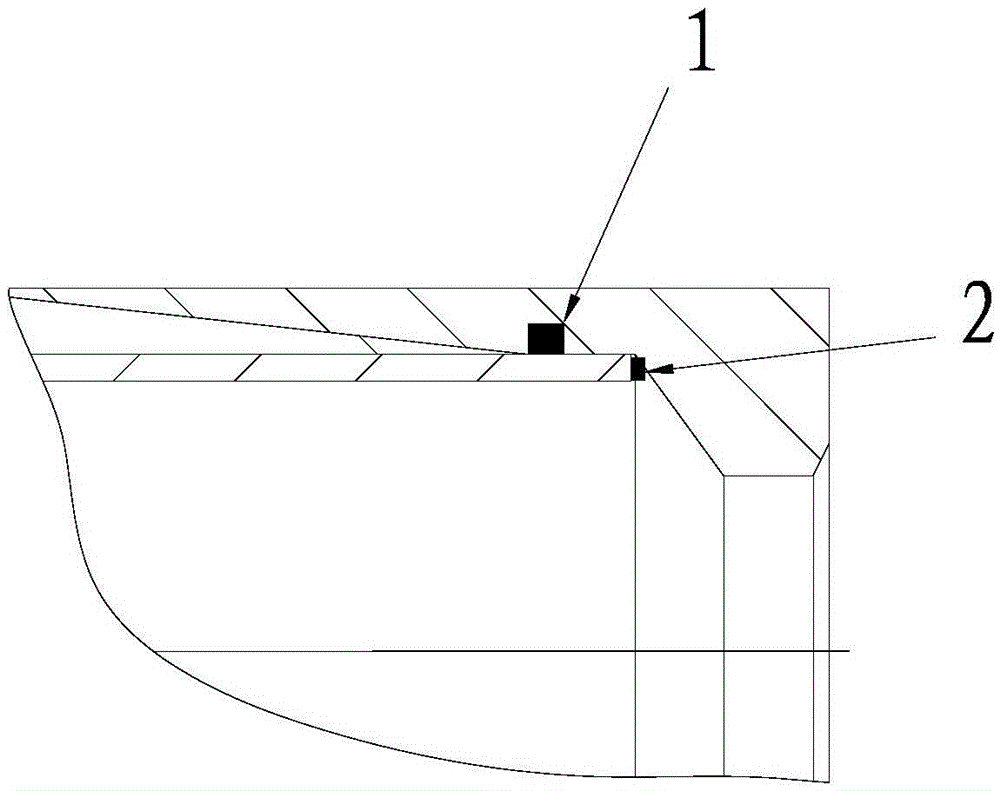

[0027] Guarantee measures for the brazing gap: The brazing method of the pipe end of the embedded casing pipe with a partially visible bellows is to control the processing size tolerance of a single part and design the expansion mold of the pipe end, as shown in the attached figure 1 After the mold is expanded, mechanical processing is carried out to ensure that the brazing gap between the bellows pipe end and the jacket is 0.06mm after the parts are combined and assembled; the parts are combined and assembled using a fixture to control the assembly size;

[0028] Brazing material selection and thermal cycle: local visible corrugated tube embedded casing pipe end brazing method, where the joint is welded with stainless steel materials and high-temperat...

Embodiment 2

[0041] This embodiment provides a method for brazing the end of a slender and embedded casing pipe, which is characterized in that the brazing method for the end of a slender and embedded casing includes the following content:

[0042] Guarantee measures for the brazing gap: The brazing method of the pipe end of the embedded casing pipe with a partially visible bellows is to control the processing size tolerance of a single part and design the expansion mold of the pipe end, as shown in the attached figure 1 After the mold is expanded, mechanical processing is carried out to ensure that the brazing gap between the bellows pipe end and the jacket is 0.08mm after the parts are combined and assembled; the parts are combined and assembled using a fixture to control the assembly size;

[0043] Brazing material selection and thermal cycle: local visible corrugated tube embedded casing pipe end brazing method, where the joint is welded with stainless steel materials and high-temperatu...

Embodiment 3

[0056] This embodiment provides a method for brazing the end of a slender and embedded casing pipe, which is characterized in that the brazing method for the end of a slender and embedded casing includes the following content:

[0057] Guarantee measures for the brazing gap: The brazing method of the pipe end of the embedded casing pipe with a partially visible bellows is to control the processing size tolerance of a single part and design the expansion mold of the pipe end, as shown in the attached figure 1 After the mold is expanded, mechanical processing is carried out to ensure that the brazing gap between the bellows pipe end and the jacket is 0.1mm after the parts are assembled; the parts are assembled using a fixture to control the assembly size;

[0058] Brazing material selection and thermal cycle: local visible corrugated tube embedded casing pipe end brazing method, where the joint is welded with stainless steel materials and high-temperature alloy materials, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com