Honeycomb display panel and preparation method thereof

A technology for display boards and manufacturing methods, applied to chemical instruments and methods, other household appliances, lamination, etc., can solve problems such as heavy weight, poor integrity of display boards, and easy to be affected by external environments such as weather, etc., to improve the use of Long life, excellent mechanical properties, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

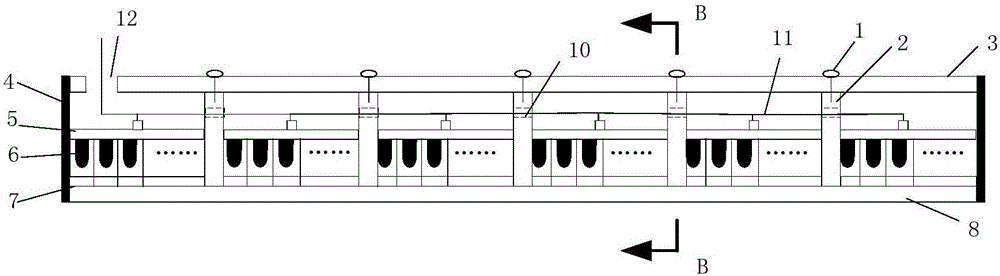

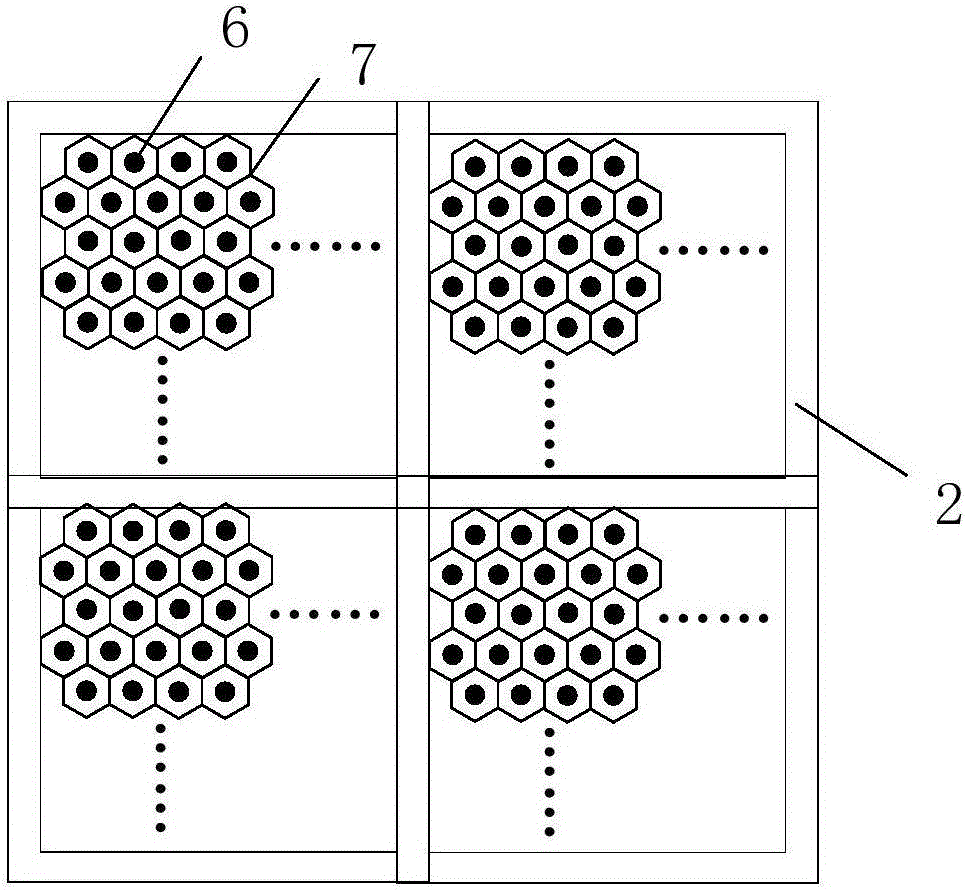

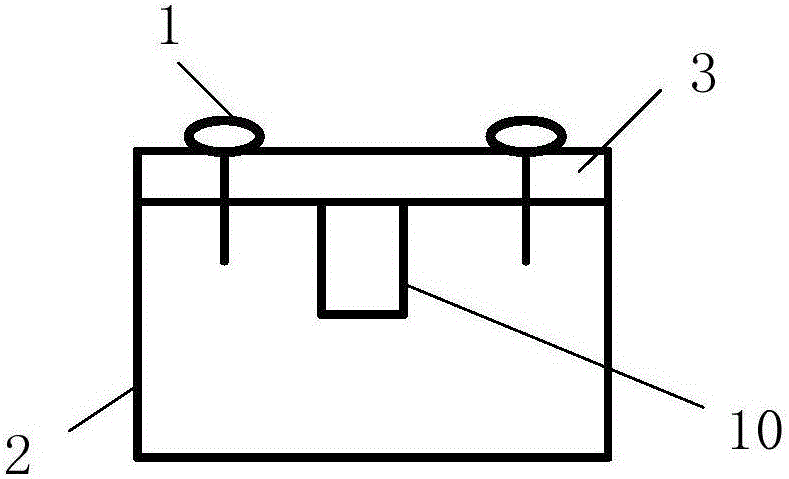

[0033] Such as Figure 1-4 As shown, a honeycomb display panel includes a transparent panel 8, a frame 2 and a skin 3, the frame 2 is arranged between the panel 8 and the skin 3, the frame 2 is composed of a plurality of longitudinal ribs and transverse ribs, A plurality of sash units with equal areas are formed; a honeycomb core board 7 and a PCB circuit board 5 are embedded in each sash unit, and each PCB circuit board 5 is provided with a honeycomb core cell on the corresponding honeycomb core board. The same number of LED lamp beads 6, and one LED lamp bead 6 is embedded in each honeycomb core cell, the honeycomb core cell is a regular hexagon, the transparent panel 8 is located on the side close to the LED lamp beads, the PC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com