Diatom ooze wall paint and preparation method thereof

A wall paint and diatom mud technology, applied in the field of wall paint, can solve the problems of long time, powder loosening, softening, etc., and achieve the effect of keeping beautiful as new, avoiding mildew, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

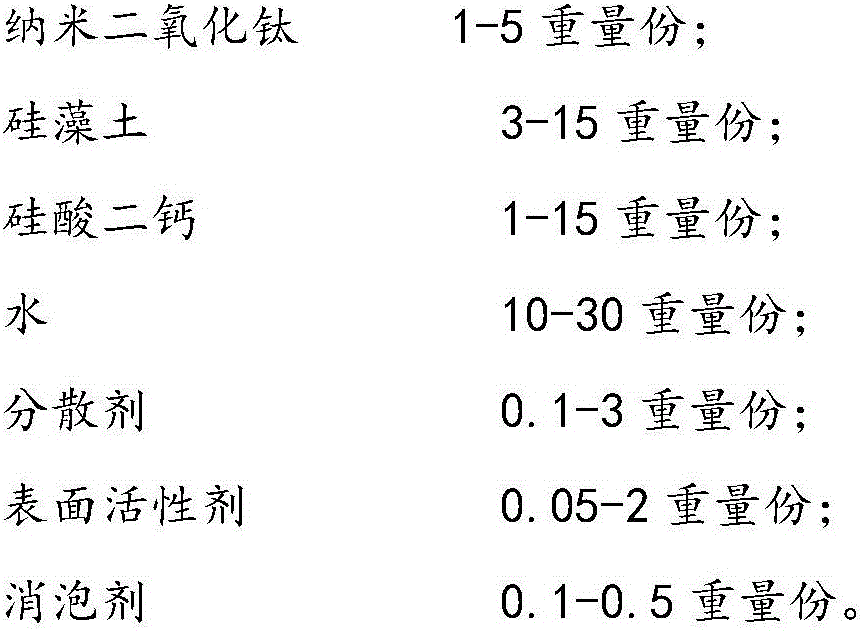

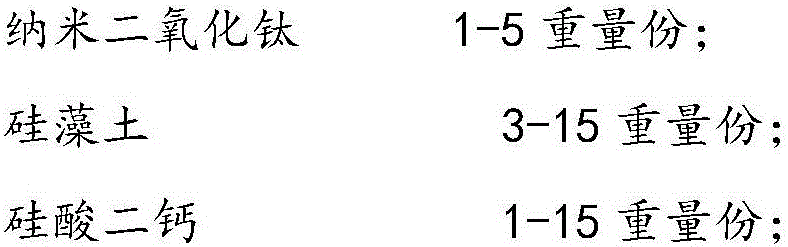

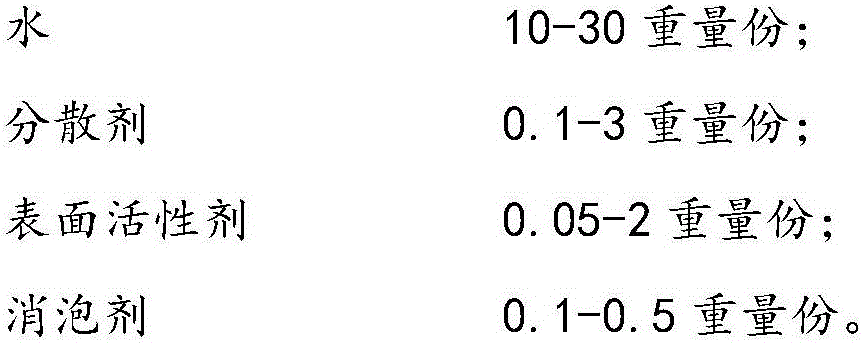

[0019] The embodiment of the present invention discloses a preparation method of diatom mud wall paint, comprising the following steps: adding diatomite, nanometer titanium dioxide and dicalcium silicate to the zinc nitrate solution, adjusting the pH value of the solution to 4-6, and React at 60-80°C, suction filter, dry, and grind to obtain a powder mixture; add dispersant, surfactant, defoamer, pigment and water to the powder mixture, and stir to obtain a diatom mud wall top coat.

[0020] The diatom mud wall paint prepared by the invention has multiple functions such as automatically adjusting air humidity, purifying air, absorbing and decomposing chemical substances that cause human allergies, eliminating peculiar smell, treating indoor formaldehyde gas, absorbing smoke, preventing mold and mites, and the like. It can gradually strengthen the hardness of wall paint by gradually absorbing moisture in the air.

[0021] In the present invention, the nano-titanium dioxide add...

Embodiment 1

[0038] Prepare a 0.2mol / L zinc nitrate solution in advance, add 300-500 mesh diatomite, nano-titanium dioxide and dicalcium silicate (dicalcium silicate: zinc nitrate solution = 30% weight ratio) under stirring conditions; adjust the solution The pH value is 5; the reaction is heated and stirred at 60-80°C for more than 1 hour, filtered with water, dried, and ground to obtain a powdery mixture of diatom mud wall paint. When using, add dispersant, defoamer, surfactant and a certain proportion of water to the above powdery mixture, stir well and smear it on the wall; water spray test for more than 2 hours; there is no softening feeling when touched by hands, and no feeling of softening when kicked. Deformed, no footprints.

[0039] The weight ratio of described nano titanium dioxide and zinc nitrate solution is 1:10; The weight ratio of described diatomite and zinc nitrate solution is 3:10; The dispersant, surfactant, defoamer and diatom mud wall The volume ratio of the top coa...

Embodiment 2

[0042] Prepare a 0.2mol / L zinc nitrate solution in advance, add 300-500 mesh diatomite, nano-titanium dioxide and dicalcium silicate (dicalcium silicate: zinc nitrate solution = 10% weight ratio) under stirring conditions; adjust the solution The pH value is 5; the reaction is heated and stirred at 60-80°C for more than 1 hour, filtered with water, dried, and ground to obtain a powdery mixture of diatom mud wall paint. When in use, add dispersant, defoamer, surfactant and a certain proportion of water to the above powder mixture, stir well and apply it on the wall; use a shower to sprinkle water, 0.5 kg per square meter, and there is no softening feeling when touched by hand. Kicking slightly deformed.

[0043] The weight ratio of described nano titanium dioxide and zinc nitrate solution is 1:10; The weight ratio of described diatomite and zinc nitrate solution is 3:10; The dispersant, surfactant, defoamer and diatom mud wall The volume ratio of the top coat is 3:0.5:3:100. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com