Heat dissipation resin composition for LED substrate and preparation method thereof

A technology of resin composition and LED substrate, applied in the field of heat-dissipating resin composition, can solve problems such as the increase of working temperature of LED chips, and achieve the effects of improving lifespan and suppressing the increase of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method for a heat-dissipating resin composition for an LED substrate, comprising:

[0045] Step 1) prepare epoxy resin A,

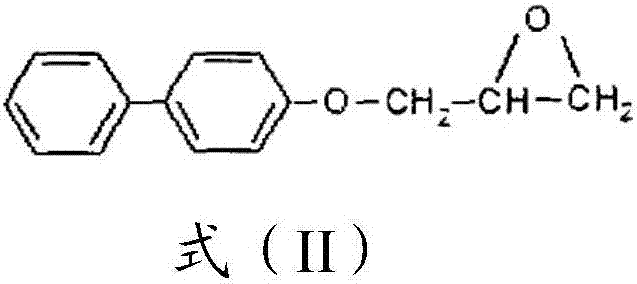

[0046] Step 1.1) prepare the epoxy compound B of formula (II) structure,

[0047] Dissolve 4-hydroxybiphenyl in excess epichlorohydrin, add potassium hydroxide, the molar ratio of 4-hydroxybiphenyl to potassium hydroxide is 1.2, react at 100°C for 4 hours, and distill the unreacted ring under reduced pressure Oxychloropropane, the product of vacuum distillation is washed with distilled water, and dried to obtain epoxy compound A;

[0048]

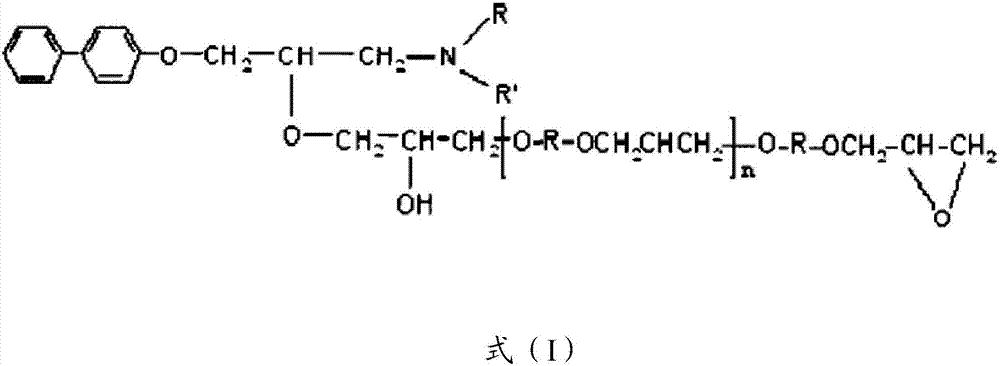

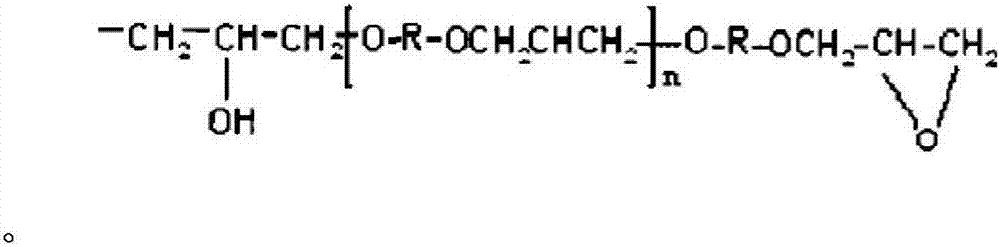

[0049] Step 1.2), mix epoxy compound B, R-N(H)-R', R and R' connected to N are C2 alkyl and C4 linear alkyl respectively, react at 110°C for 2min, add epoxy resin CYD -128, stirred and mixed evenly, reacted for 10min, cooled to room temperature, extracted with toluene and dried in vacuum to obtain epoxy resin A;

[0050] Step 2), disperse 60% by mass of epoxy resin A in water, add 30% by mass...

Embodiment 2

[0052] A preparation method for a heat-dissipating resin composition for an LED substrate, comprising:

[0053] Step 1) prepare epoxy resin A,

[0054] Step 1.1) prepare the epoxy compound B of formula (II) structure,

[0055] Dissolve 4-hydroxybiphenyl in excess epichlorohydrin, add potassium hydroxide, the molar ratio of 4-hydroxybiphenyl to potassium hydroxide is 1.2, react at 100°C for 4 hours, and distill the unreacted ring under reduced pressure Oxychloropropane, the product of vacuum distillation is washed with distilled water, and dried to obtain epoxy compound A;

[0056]

[0057] Step 1.2), mix epoxy compound B, R-N(H)-R', R and R' connected to N are C3 straight-chain alkyl and C6 straight-chain alkyl respectively, react at 110°C for 3 minutes, add epoxy Resin CYD-128, stirred and mixed evenly, reacted for 13 minutes, cooled to room temperature, extracted with toluene and dried in vacuum to obtain epoxy resin A;

[0058] Step 2), disperse 70% by mass of epoxy r...

Embodiment 3

[0060] A preparation method for a heat-dissipating resin composition for an LED substrate, comprising:

[0061] Step 1) prepare epoxy resin A,

[0062] Step 1.1) prepare the epoxy compound B of formula (II) structure,

[0063] Dissolve 4-hydroxybiphenyl in excess epichlorohydrin, add potassium hydroxide, the molar ratio of 4-hydroxybiphenyl to potassium hydroxide is 1.1, react at 100°C for 4 hours, and distill the unreacted ring under reduced pressure Oxychloropropane, the product of vacuum distillation is washed with distilled water, and dried to obtain epoxy compound A;

[0064]

[0065] Step 1.2), mix epoxy compound B, R-N(H)-R', R and R' connected to N are C4 straight-chain alkyl and C6 straight-chain alkyl respectively, react at 110°C for 3 minutes, add epoxy Resin CYD-128, stirred and mixed evenly, reacted for 15 minutes, cooled to room temperature, extracted with toluene and dried in vacuum to obtain epoxy resin A;

[0066] Step 2), disperse 60% by mass of epoxy r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com