Photosensitive ink and its preparation method and application

A photosensitive ink and photoinitiator technology, applied in the field of ink, can solve the problems of high cost, difficult mass production, and low yield rate of curved glass or ceramic surface decoration, and achieve low cost, high yield rate, and guaranteed appearance decoration effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides the preparation method of the above-mentioned photosensitive ink, comprising the following steps: (1) mixing the alkali-soluble UV resin, quick-drying solvent, UV monomer, photoinitiator, pigment, filler and auxiliary agent uniformly and grinding to obtain the component A; Mix and grind epoxy resin, epoxy curing accelerator, slow-drying solvent, filler and coupling agent evenly to obtain component B; (2) Mix component A and component B in proportion to obtain photosensitive ink. The preparation method of the above-mentioned photosensitive ink is simple and easy, has high yield rate and low cost, and is suitable for mass production. The prepared photosensitive ink is suitable for surface decoration of glass and ceramics, especially surface decoration of multi-curved surfaces.

[0050] Preferably, in the above-mentioned preparation method, the components are mixed while stirring, and the speed of the mixer is 500-1000 rpm. After mixing e...

Embodiment 1

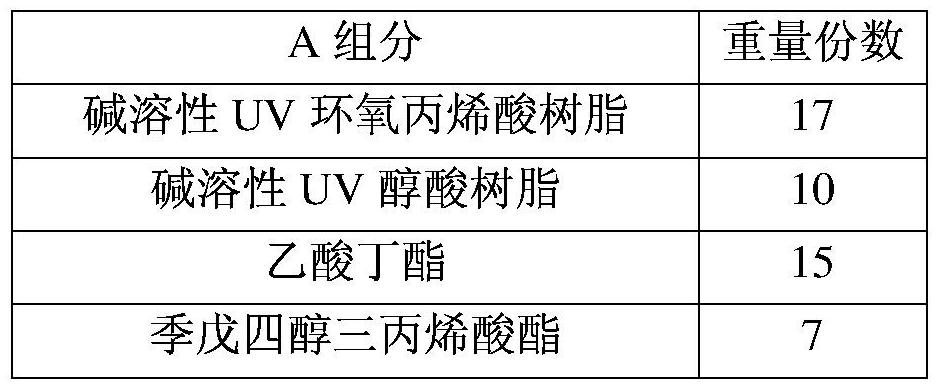

[0056] A preferred embodiment of the present invention provides a photosensitive ink, and the composition of component A and component B is shown in Table 1.

[0057] The composition of photosensitive ink in table 1 embodiment 1

[0058]

[0059]

[0060] The preparation method of the above-mentioned photosensitive ink is as follows: the rotating speed of the mixer is 800 rpm, and the materials in the A component in Table 1 are sequentially added while stirring. Grind on a three-roller machine to a fineness of ≤5μ; the speed of the mixer is 800 rpm, and the materials in component B in Table 1 are added in turn while stirring, and after mixing evenly, disperse at a speed of 2500 rpm for 25 minutes. Then grind on a three-roller machine to a fineness of ≤5μ; mix the above-mentioned component A and component B according to a weight ratio of 5:1 to obtain photosensitive ink.

Embodiment 2

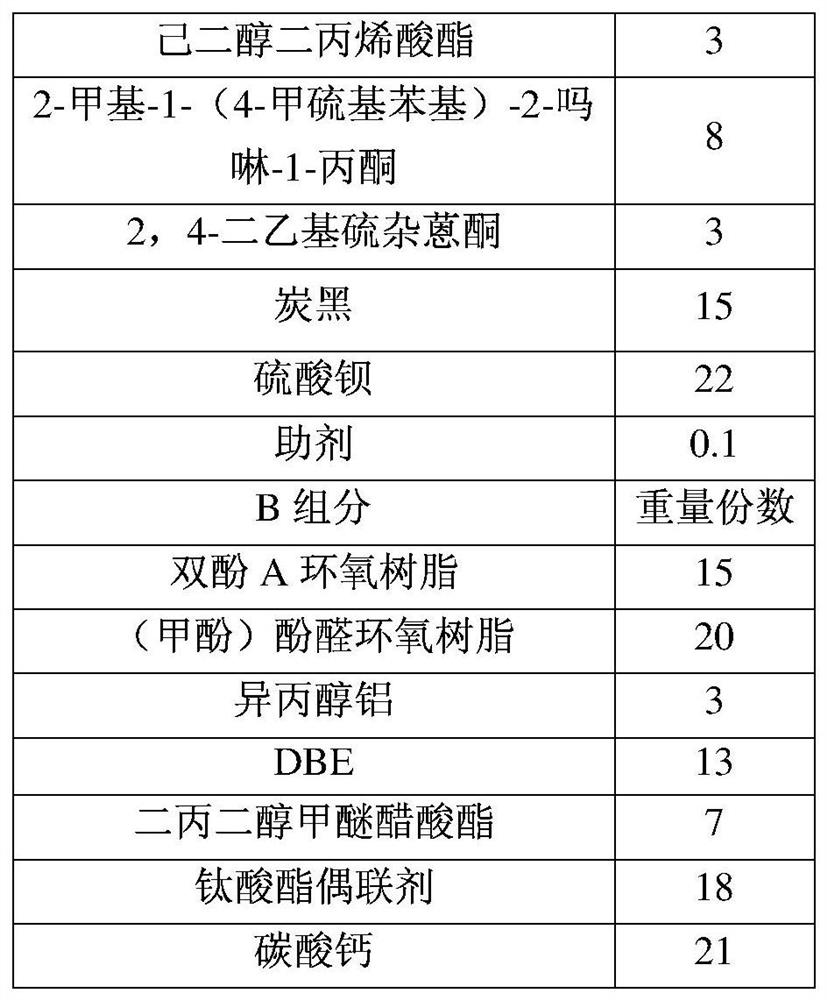

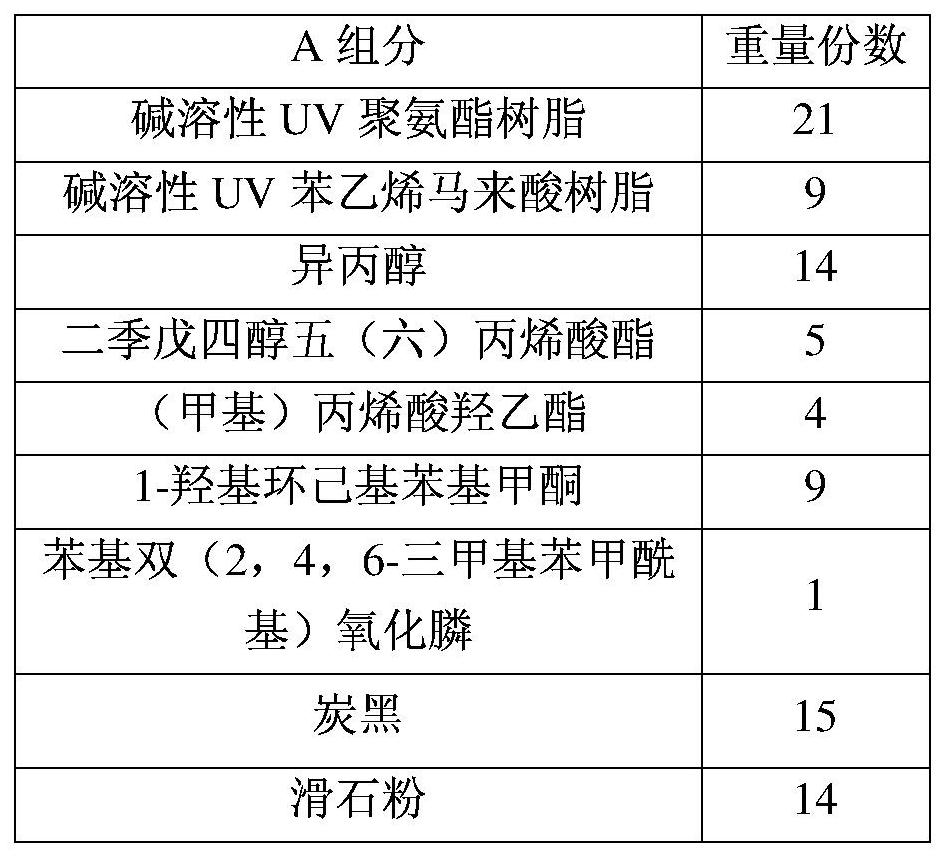

[0062] A preferred embodiment of the present invention provides a photosensitive ink, and the compositions of components A and B are shown in Table 2.

[0063] The composition of photosensitive ink in table 2 embodiment 2

[0064]

[0065]

[0066] The preparation method of above-mentioned photosensitive ink is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com