Two-step degradation method for pectin in tobacco sheets

A pectin and tobacco technology, applied in the directions of tobacco, tobacco treatment, microorganism-based methods, etc., can solve the problems of insufficient degradation, difficult control of the degradation process, and poor targeting of pectin degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The pectinase prepared by fermentation of Aspergillus honey provided in this example is obtained through the following production steps.

[0058] (1) Activation of the strains, pick the fermentation strains from the preservation medium, inoculate them into the activation medium and activate them at 30°C for about 3 days;

[0059] The fermentation strain is specifically the Aspergillus honeysuckle with the preservation number 40926 preserved by the China Industrial Microorganism Collection Center (CICC); the strains used in this example were purchased from the corresponding preservation unit;

[0060] The activation medium is a PDA medium; when inoculating the activation medium after picking bacterial strains from the preservation medium, the streaking method is used to inoculate;

[0061] The PDA culture medium is prepared according to conventional methods, specifically: 1.0L of potato extract, 20.0g of glucose, 15.0g of agar, and natural pH;

[0062] The preparation m...

Embodiment 2

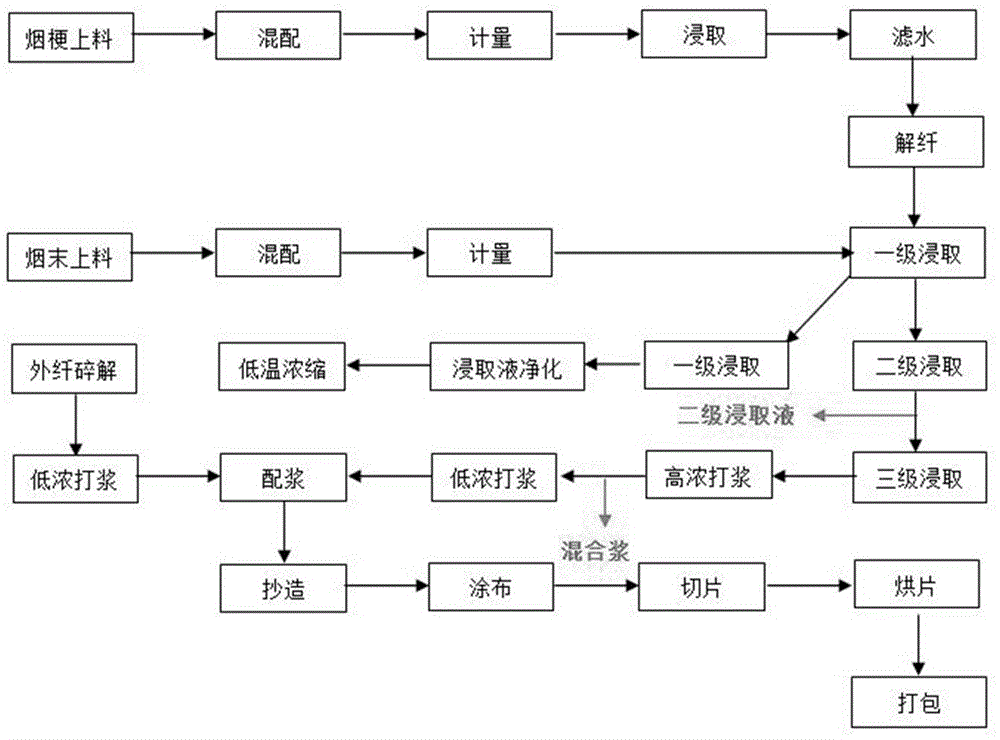

[0074] The crude enzyme liquid prepared in Example 1 was applied to the two positions of the secondary leachate and the mixed pulp on the production line of China Tobacco Tobacco in Henan Province respectively (the process position is as follows: figure 1 shown), used to degrade the pectin component in the leach solution and slurry.

[0075] The specific method of use is to use the crude enzyme liquid of pectinase prepared in Example 1 (the enzyme activity is 2432.63U / mL, theoretically, the crude enzyme liquid with any enzyme activity prepared in Example 1 can be used to degrade pectin application, but in order to determine better degradation conditions and the actual improvement effect on tobacco, so only the crude enzyme solution prepared in Example 1 with an enzyme activity of 2432.63U / mL was used as an example for the experiment) to carry out appropriate dilution, and then the crude enzyme solution after dilution Enzyme solution is based on different material ratios (the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap