A device for preparing a gradient nanostructure on the surface of a high-strength and high-hardness metal material

A metal material, surface gradient technology, applied in nanotechnology and other directions, can solve problems such as low hardness, and achieve the effects of low processing cost, simple and reliable method, and increased depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments.

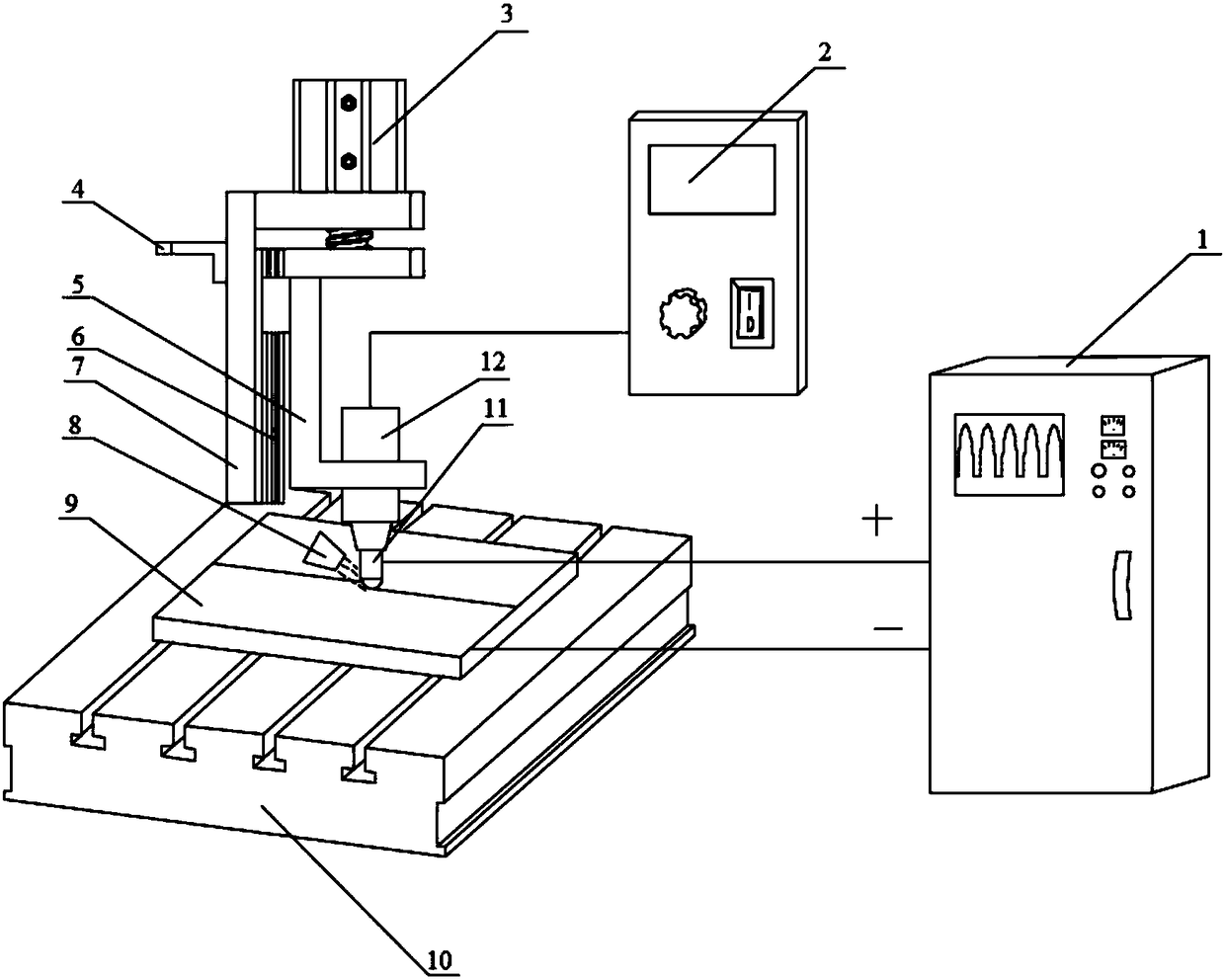

[0023] refer to figure 1 , a device for preparing a gradient nanostructure on the surface of a high-strength and high-hardness metal material, including a tool head 11, a high instantaneous energy density pulse power supply 1, an ultrasonic generator 2, a cylinder 3, a support frame 4, a nozzle 8, a sliding guide rail 5, a guide rail seat 7, Ultrasonic transducer 12, workbench 10; the workpiece 9 made of high-strength and high-hardness metal material is installed on the workbench 10, and the workbench 10 can move in the X-axis and Y-axis directions of the machine tool, and then drives the workpiece 9 in the X-axis and Y-axis of the machine tool Move in the axial direction, the tool head 11 and the workpiece 9 are respectively connected to the positive pole and the negative pole of the high instantaneous energy density pulse power supply 1, the tool head 11 is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com