Method for preparing lithium sulfide electrode based on electrochemical means

A lithium sulfide, electrochemical technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low utilization rate of active materials, poor cycle stability, low coulombic efficiency of lithium-sulfur batteries, etc. Achieving the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the process and solutions of the present invention, the following inventions will be further described in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

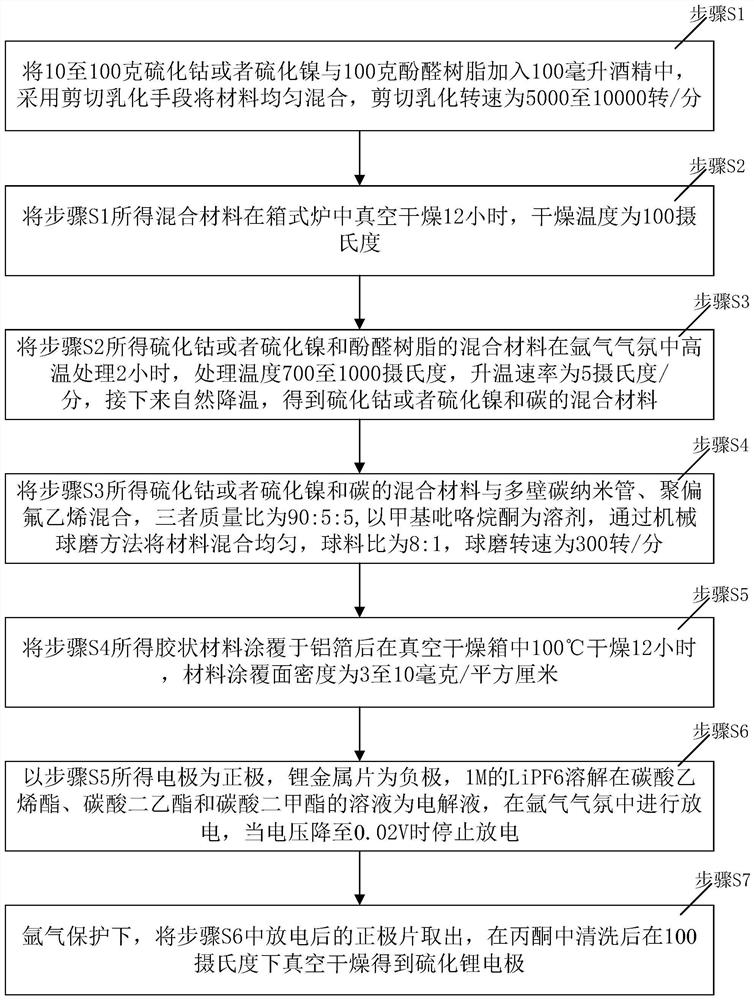

[0026] The present invention proposes a method for preparing lithium sulfide electrodes based on electrochemical means, see figure 1 shown, including the following steps:

[0027] S1, add 10 to 100 grams of cobalt sulfide or nickel sulfide and 100 grams of phenolic resin into 100 ml of alcohol, and use shear emulsification to mix the materials evenly, and the shear emulsification speed is 5000 to 10000 rpm;

[0028] S2, the mixed material obtained in S1 is vacuum-dried in a box furnace for 12 hours, and the drying temperature is 100 degrees Celsius;

[0029] S3, treating the mixed material of cobalt sulfide or nickel sulfide and phenolic resin obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com