Circulating-moving type horizontally-arranged air way forepoling unit

An advanced bracket and mobile technology, which is applied in the direction of pillars/brackets, top beams supporting mine roofs, railway car body parts, etc., can solve problems such as inconvenient movement, small contact area, and reduced support performance, and achieve disassembly and maintenance. The effect of simple installation, accurate parking position and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

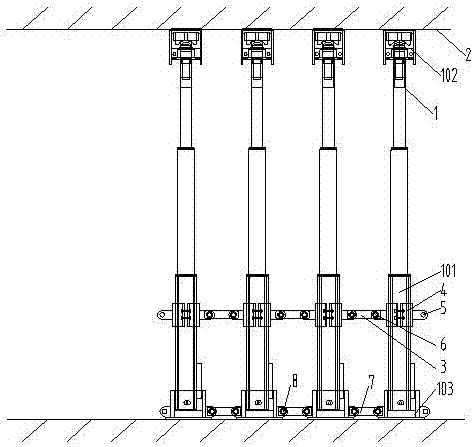

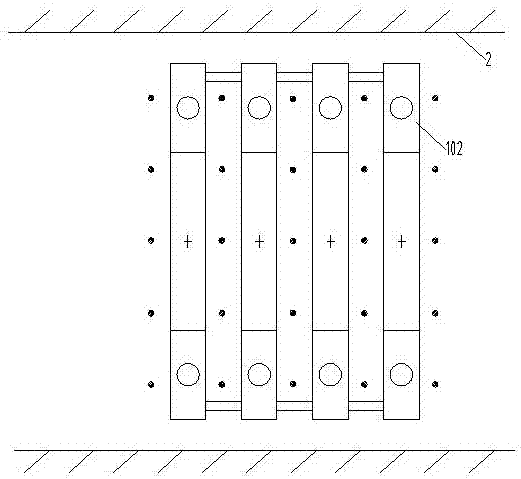

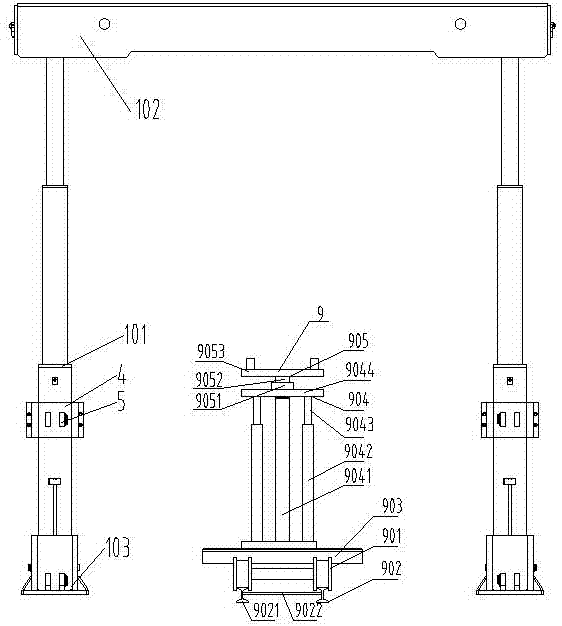

[0033] As shown in the figure, a cyclically movable type of horizontally arranged air lane leading support group includes a plurality of leading support units 1 arranged at intervals along the length direction of the roadway 2, and a leading support unit 1 is arranged below the leading support unit 1 for placing the rearmost leading support unit 1 Move to the frontmost frame moving vehicle 9, the frame moving vehicle 9 includes a platform 903 that is slidably arranged on the I-shaped steel track 902 through the wheel shaft 901, and the wheel shaft 901 is driven by the driving mechanism 906 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com