Cabin opening type ammunition mother bomb dissembling machine and method

A dismantling machine and parent ammunition technology, applied to ammunition, weapon accessories, offensive equipment, etc., can solve the problems of low automation and low dismantling efficiency, and achieve the effects of high automation, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

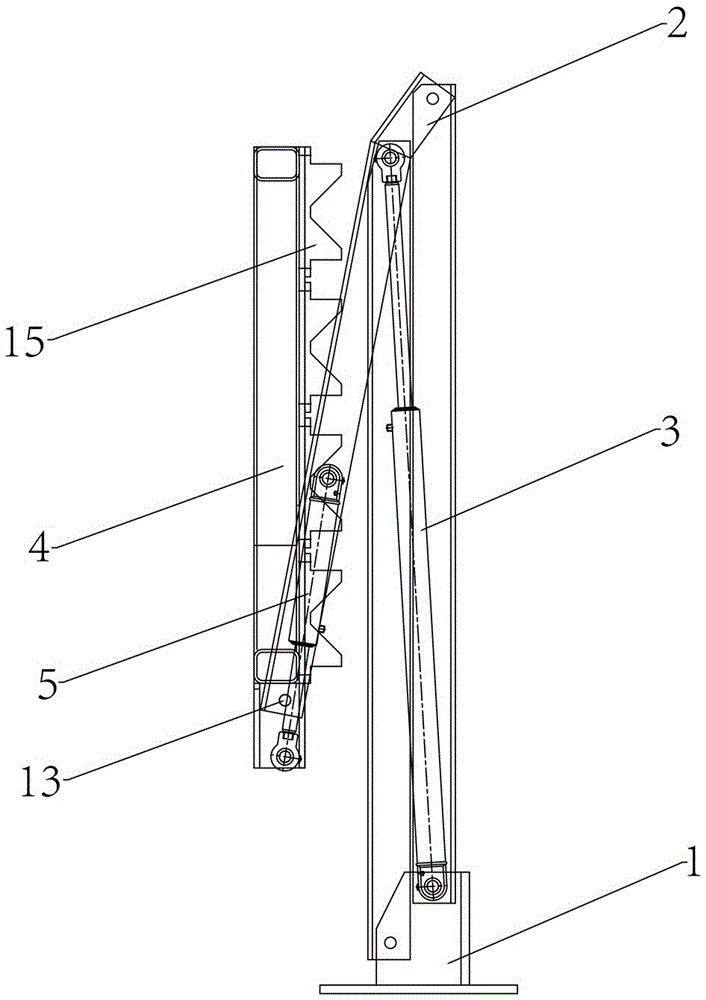

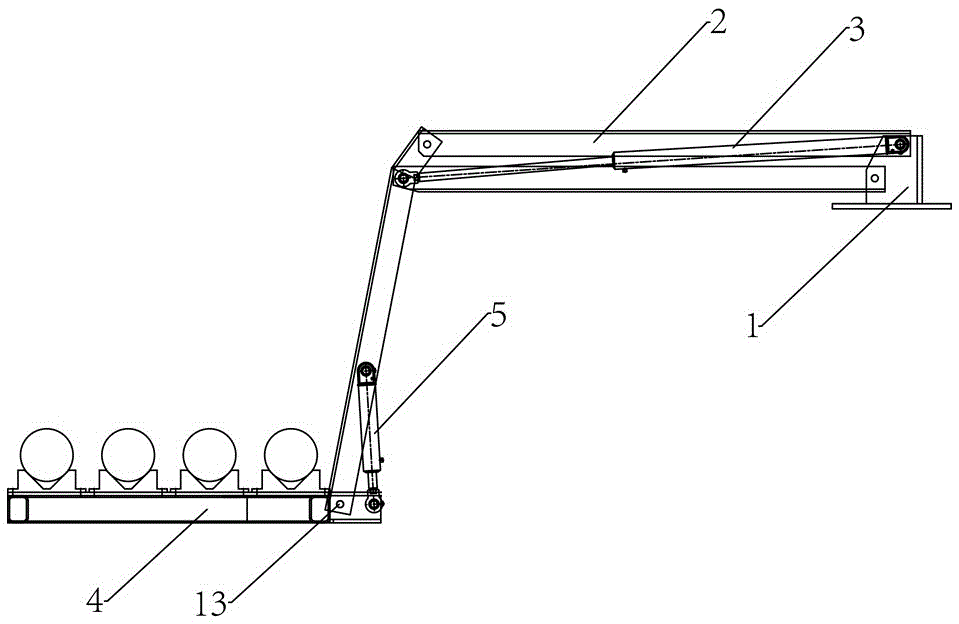

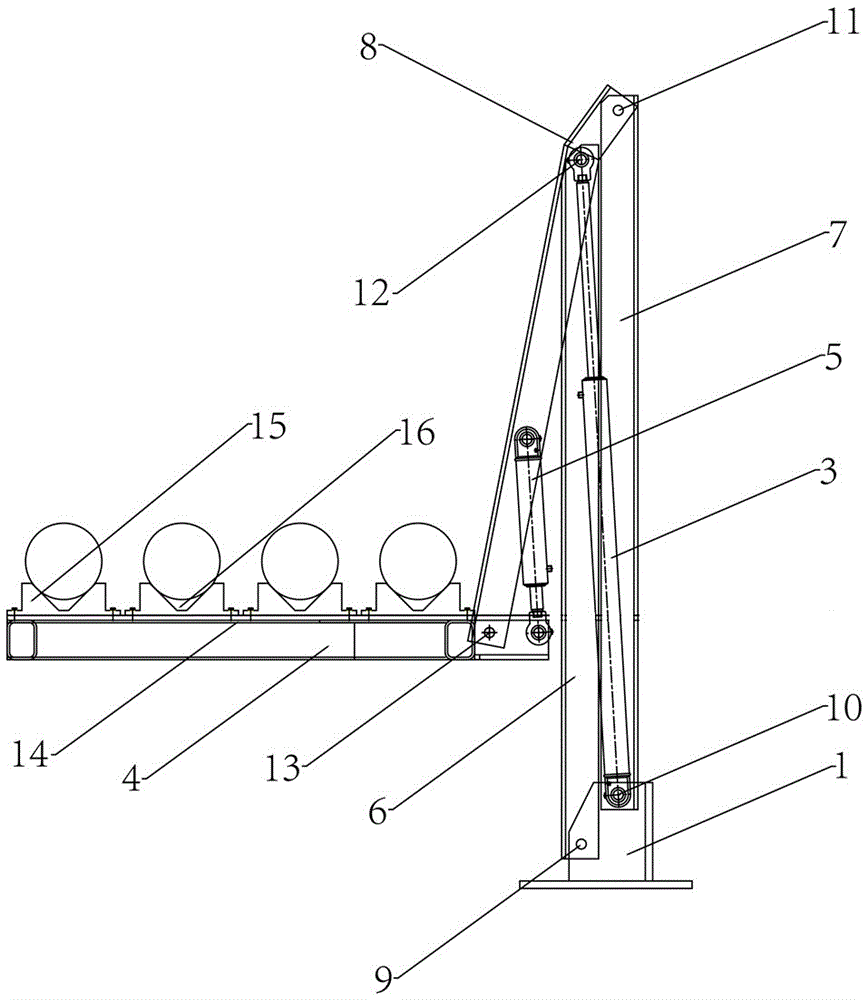

[0031] Embodiment 1: open-chamber type ammunition parent bullet decomposition machine.

[0032] The open-chamber ammunition mother shell decomposition machine of the present invention mainly includes a mother bomb lifting device for lifting the pretreated mother bomb (removed fuze, moisture-proof plug and projectile cartridge) to the operating height and a mother bomb lifting device for A bomb dismantling device for dismantling the contents (lighting torches, bullets, etc.) in the mother bomb.

[0033] Such as Figure 1~4 As shown, the bomb lifting device includes a base 1, two sets of parallel linkage mechanisms 2 relatively arranged on the base 1, a lifting cylinder 3 for driving the parallel linkage mechanisms 2, and a lifting cylinder 3 arranged between the two sets of parallel linkage mechanisms 2. The support 4, the overturning oil cylinder 5 used to drive the support 4 to turn over, and the bullet buffer mechanism arranged on the support 4.

[0034]The parallel linkag...

Embodiment 2

[0051] Embodiment 2: The decomposition method of the open-chamber type ammunition parent bullet.

[0052] The decomposition method of the open-chamber ammunition carrier of the present invention comprises the following steps:

[0053] a. Set a set of open-cabin type ammunition bomb disintegrator as mentioned above. The initial state of the bomb lifting device is that the parallel link mechanism 2 and the support 4 are all located inside the compartment and are in a vertical state. The lifting cylinder 3 The piston rod is in a retracted state, and the piston rod of the overturning cylinder 5 is in an extended state (such as figure 1 );

[0054] b. Start the mother bomb lifting device, turn over the oil cylinder 5, and the piston rod inside will retract, pulling the end of the bracket 4 to move upward, so that the frame body of the bracket 4 moves downward with the turning hinge shaft 13 as the rotating shaft. When the bracket 4 The frame changes from a vertical state to a hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com