Bolt bonding surface real contact area measurement method and device

A bolt joint surface and contact area technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of destroying the surface shape of the joint surface, the inability to obtain the real joint area, and the accuracy of the joint surface area is not accurate enough to achieve area accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

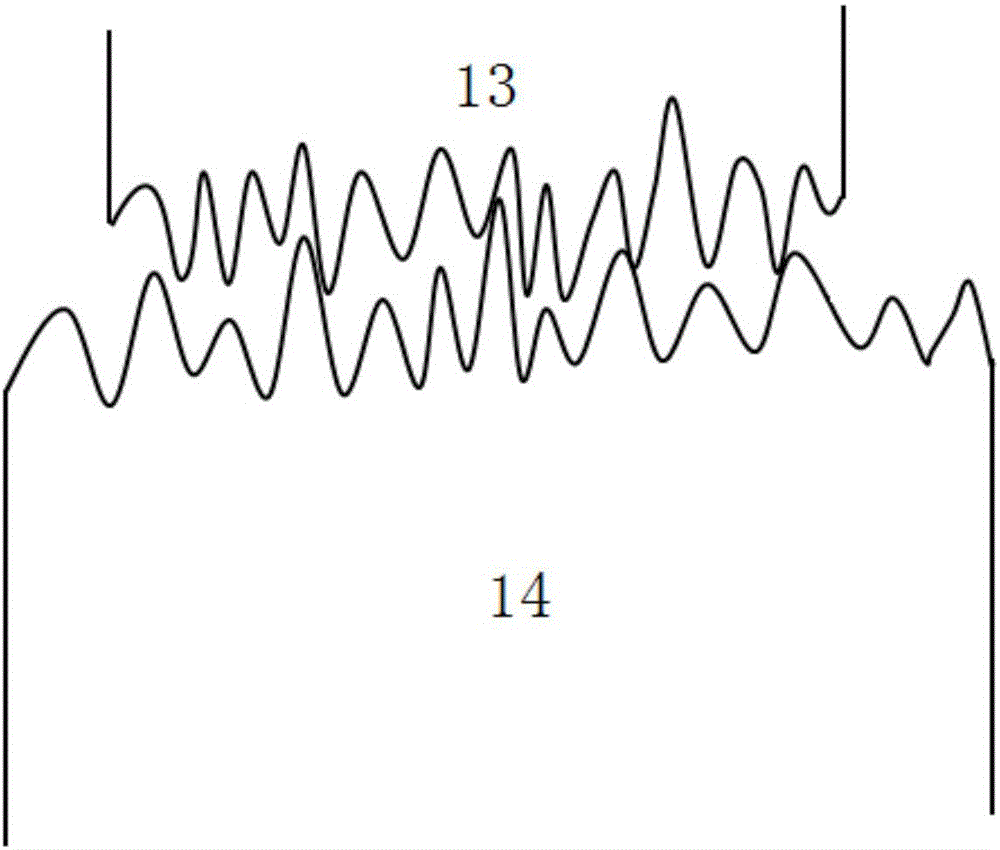

[0026] see figure 1 , the microscopic contact principle of the contact surface is: in the process of increasing the normal preload of the first part 13 and the second part 14, the asperity between the joint surfaces of the two parts deforms and starts to contact. increases, the deformation of the asperities in the contact area between the first part 13 and the second part 14 increases, and the gap in the contact area decreases until the measurable gap is zero.

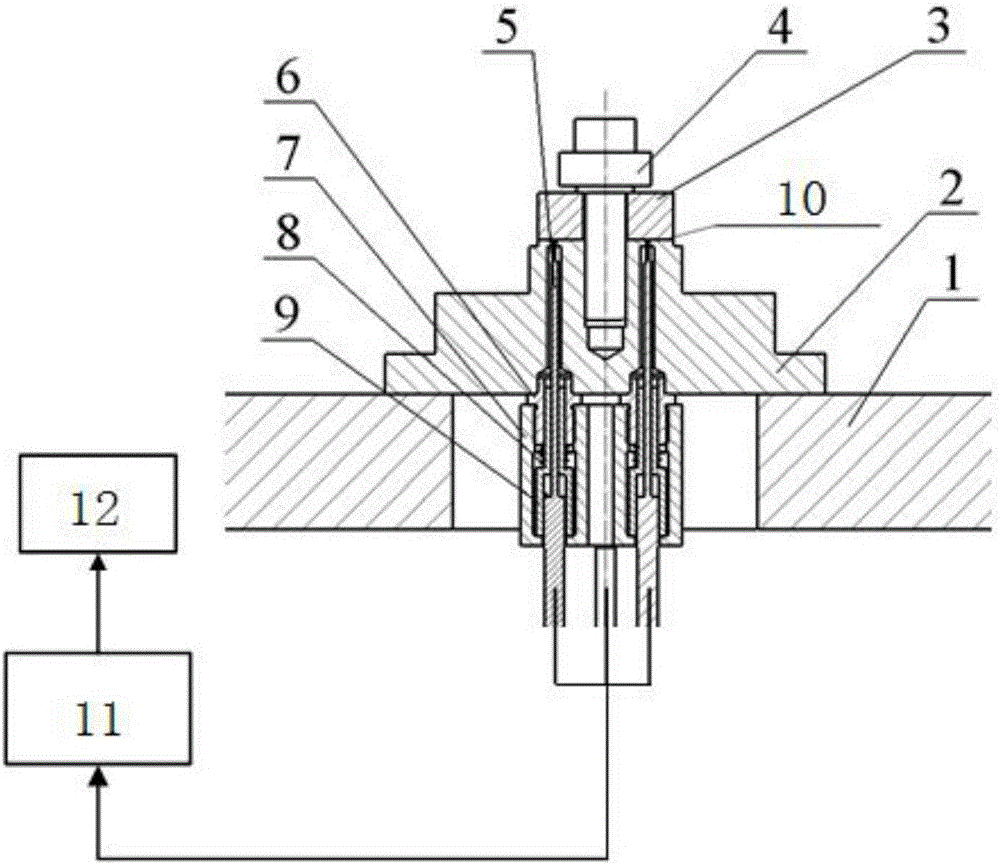

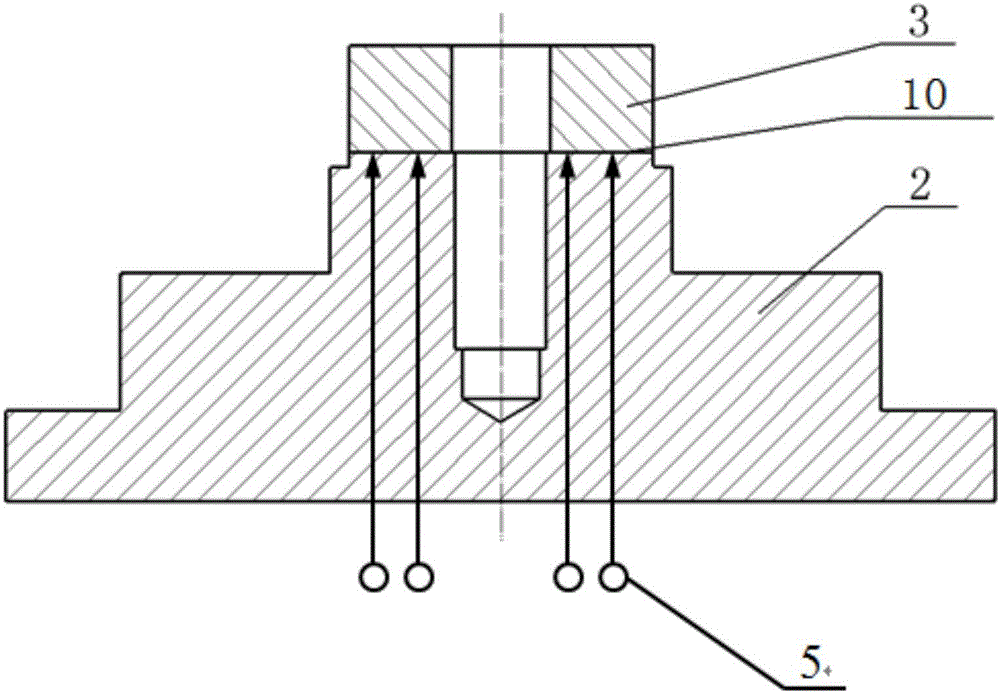

[0027] see figure 2 and image 3 , the present invention introduces high-precision nano-scale optical fiber sensors into the field of joint surface testing, and designs a set of test devices that use optical fiber sensors to measure the real joint area of bolt joint surfaces, mainly including support box base 1, lower test piece 2, and upper test piece 3 , bolt 4, nano-scale optical fiber displacement se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com