New energy vehicle air-conditioning compressor static disc two-step forming method

A technology for air-conditioning compressors and new energy vehicles, which is applied in the direction of forging/pressing/hammering machinery, wheels, vehicle parts, etc. Problems such as static plate forming quality and mass production can be solved to achieve the effect of improving service life and increasing flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

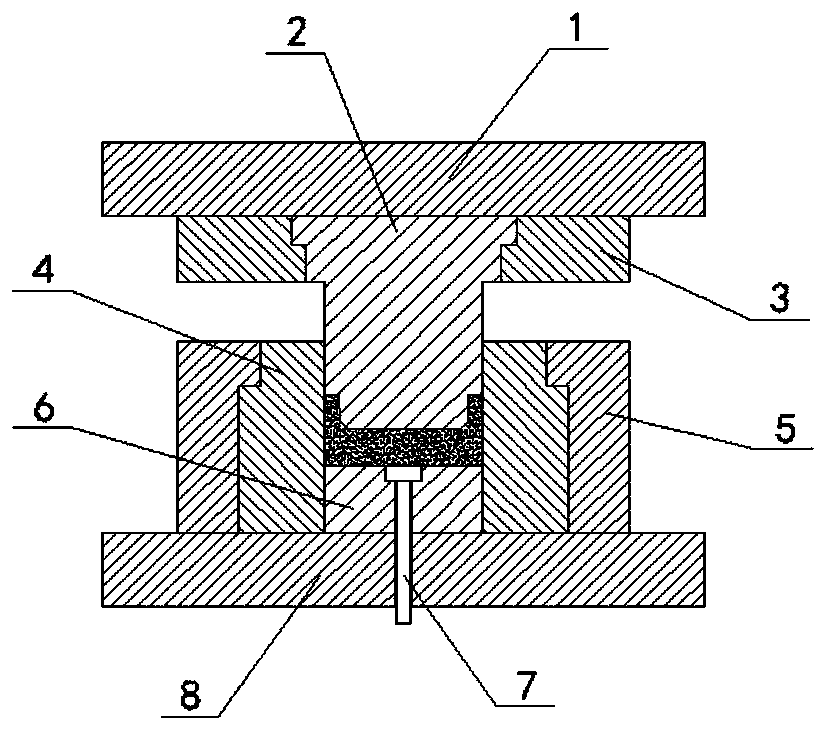

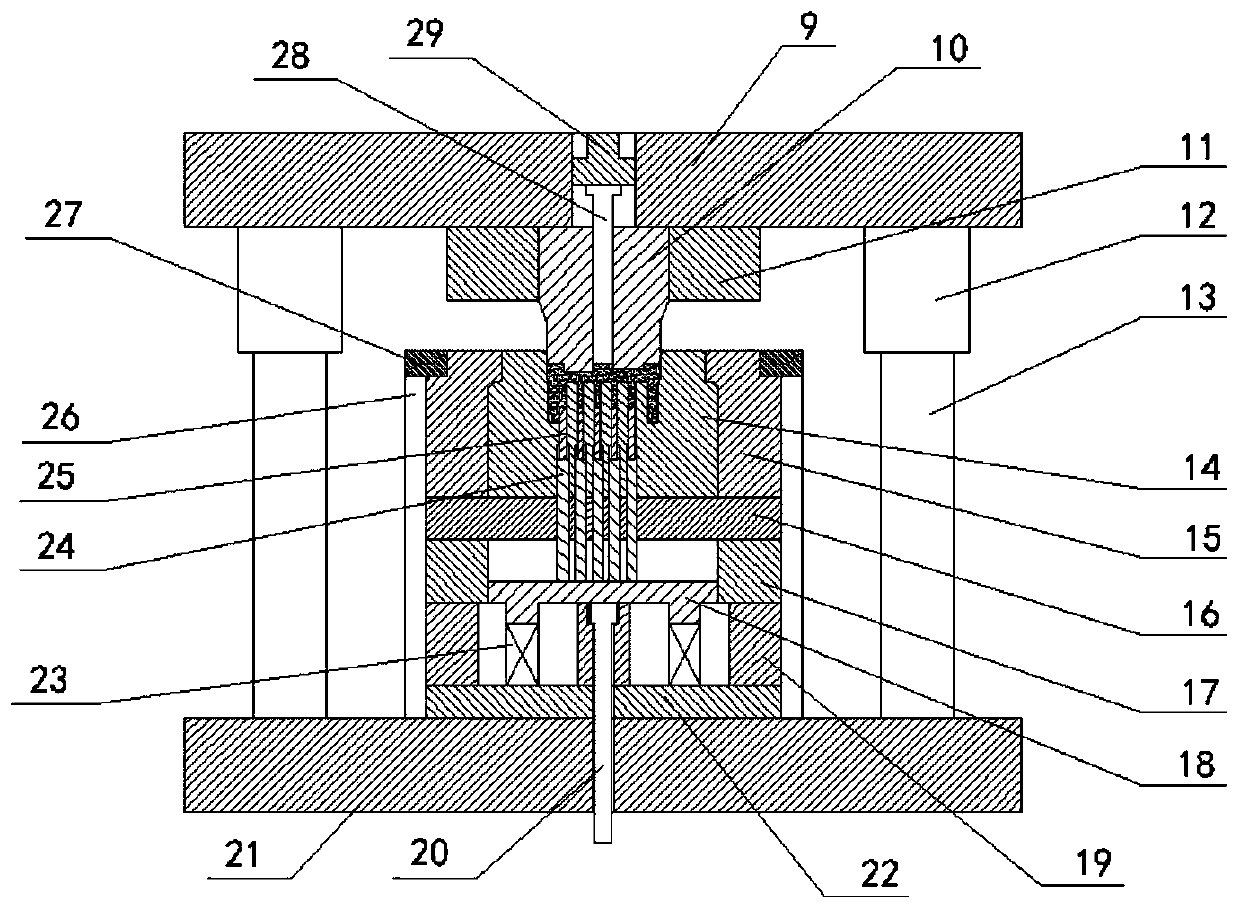

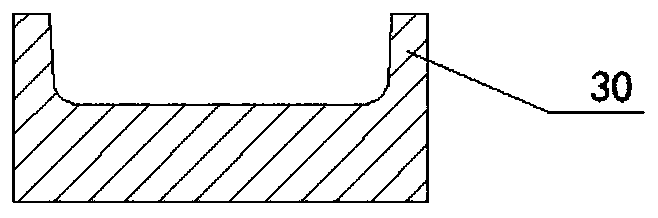

[0027] In this embodiment, the two-step forming method of the static plate of the new energy automobile air-conditioning compressor is to firstly place the blank in the pre-forging die for pre-forging to form the blank after completing blanking and blank processing to obtain the blank, so that the blank is formed to have a preset Highly pre-forged outer ring blank; then place the blank in the final forging die, and form it into a static disk by back pressure extrusion. Specifically, blanking, blank processing and forging are completed according to the following steps:

[0028] Step 1, blanking: use aluminum alloy bar as raw material, use sawing machine to blank, the diameter of the blank obtained is equal to the outer diameter of the outer ring of the static disc, and the height of the blank is determined according to the principle of constant volume.

[0029] Step 2. Billet treatment: first preheat the billet to 200°C, impregnate the preheated billet with graphite, then heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com