Multi-station impeller laser welding machine

A laser welding machine, laser welding technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of high impeller repair rate and failure rate, no positioning, interruption, etc., to reduce clamping and replacement of tooling The time of smelting and the effect of improving the working efficiency of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be better described below in conjunction with the accompanying drawings and specific embodiments.

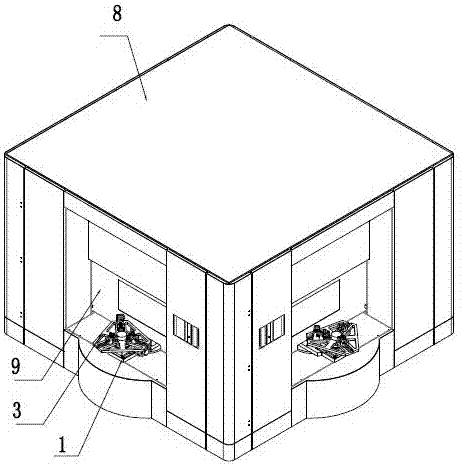

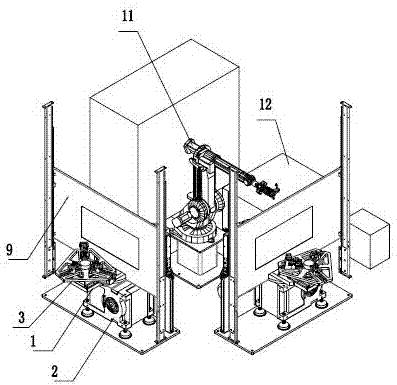

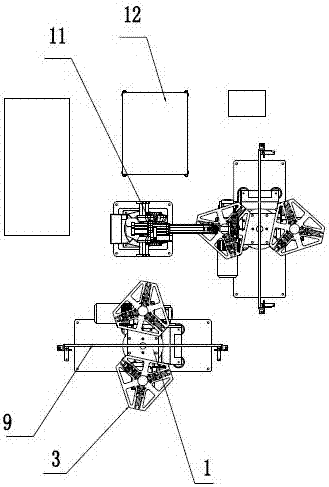

[0030] A multi-station impeller laser welding machine includes a frame 8, a laser welding robot 11, a laser 12 and a clamp assembly are arranged in the frame 8, and the clamp assembly includes a first rotary table 1, and the first rotary table 1 A rotary device 2 is installed below the table 1, and two impeller clamping mechanisms are installed on the first rotary table 1, and the impeller clamping mechanism is equidistant from the axis of rotation of the first rotary table 1. The impeller clamping mechanism includes a support plate 3 , a positioning piece 4 arranged on the support plate 3 and at least two pressing assemblies 5 , and the pressing assemblies 4 and the positioning pieces 5 are equidistantly arranged. Realize the effect of double-station or multi-station cooperation, so that one impeller clamping mechanism is in laser welding, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com