Multifunctional automatic stone cutting machine

A multi-functional, cutting machine technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problem of single cutting range and specifications of multi-piece cutting machines, troublesome operation, installation and transportation, and cutting efficiency of single-piece cutting machines Low-level problems, to achieve low product processing costs, improve cutting accuracy and quality, and occupy a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

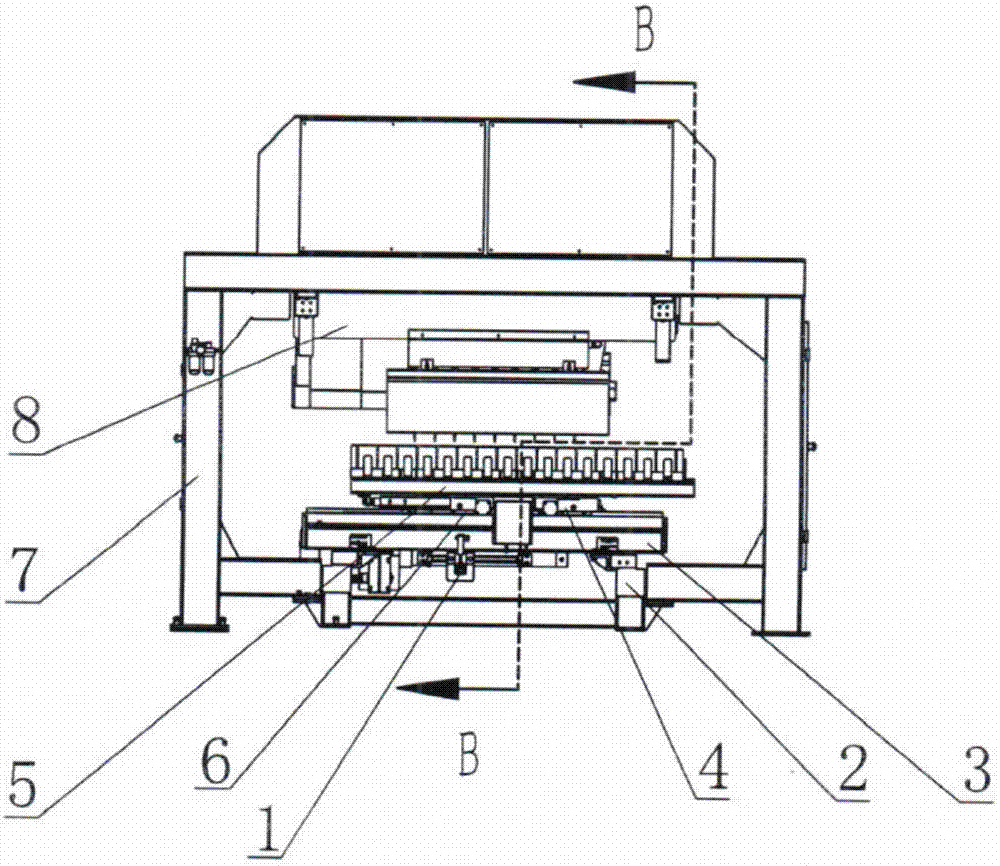

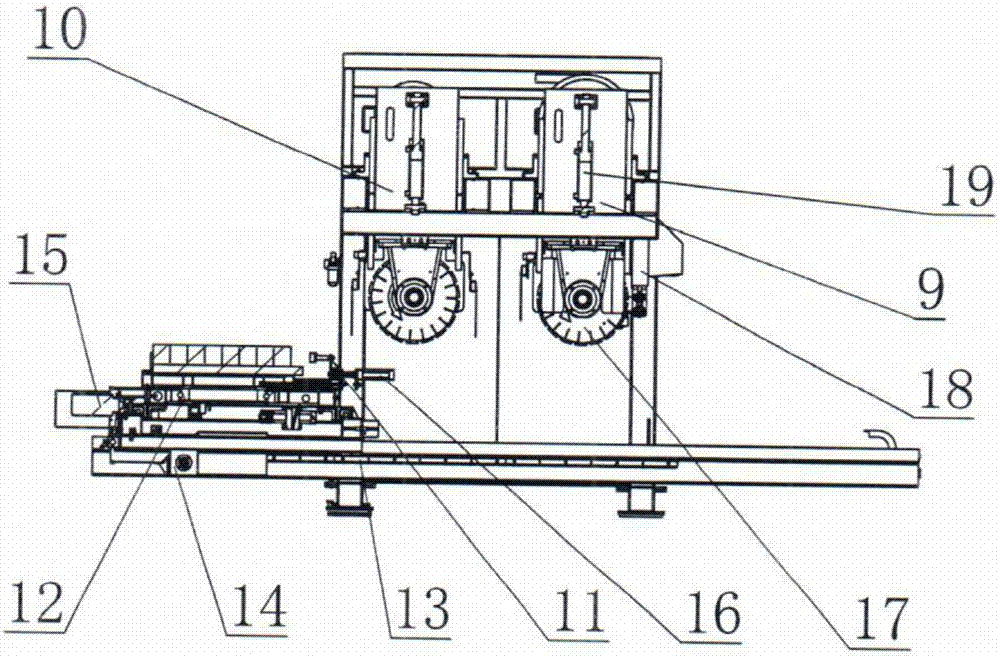

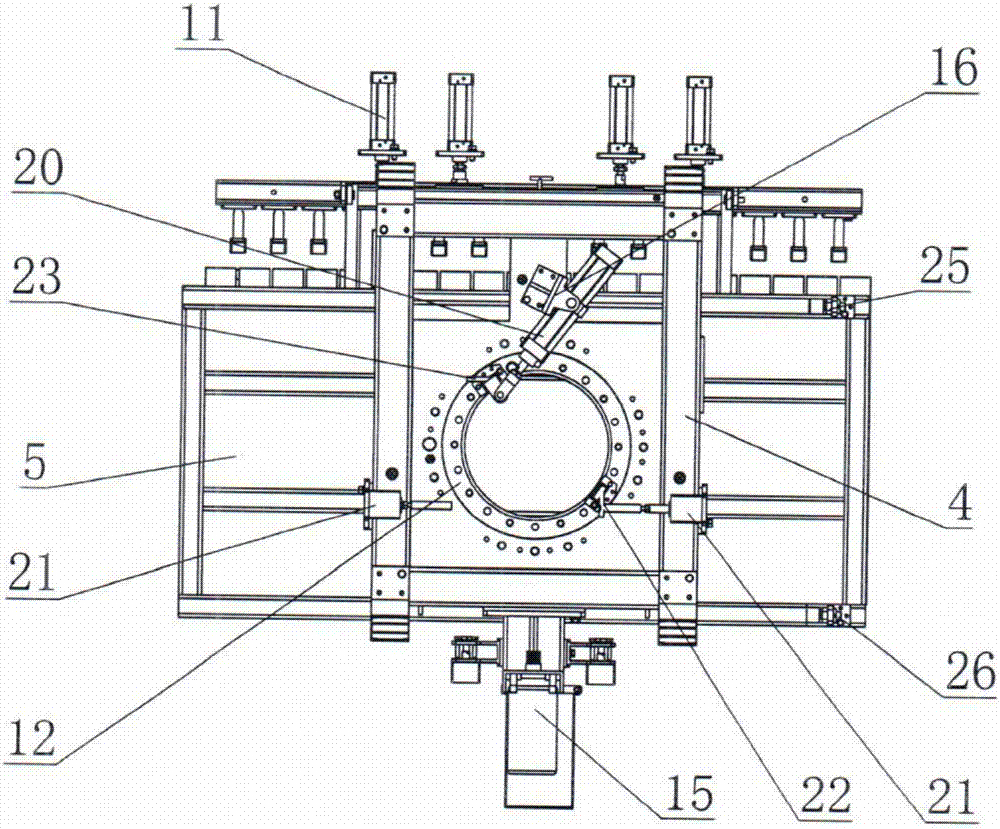

[0034] Depend on Figure 1-Figure 7 It can be seen that the multifunctional stone automatic cutting machine of the present invention includes a frame, two groups of spindle systems, a pressing device, a worktable part, a clamping device, and an automatic control system; wherein:

[0035] (1) Rack and two sets of spindle systems: refer to Figure 1-Figure 2 .

[0036]The front and back of the frame 7 are open, and the left and right sides of the frame are respectively provided with a frame door that can be opened and closed. Two groups of beams are arranged parallel to the front and rear on the upper part of the frame 7, and the two groups of main shaft systems are arranged parallelly to the front and back below the two groups of beams. Specifically, the main shaft system I is arranged under the rear side beam I29, with a pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com