Subgrade filling material produced from building construction waste and river sand and preparation method of subgrade filling material

A construction waste and subgrade filling technology, which is applied to buildings, roads, roads, etc., can solve the problems of slow progress in resource utilization of construction waste, siege of construction waste, complex processing technology, etc., to reduce natural resource consumption, rapid subsidence, and construction The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The invention will be described in detail below in conjunction with specific embodiments and accompanying drawings. The roadbed filler disclosed by the present invention is composed of river sand mixed with construction waste, wherein the proportion of river sand is about 40%, and it is taken from the Yellow River in the northwest of Jinan. The embankment is a yellow-brown loose and non-sticky single-grain structure, with a specific gravity of about 2.66; construction waste accounts for about 60%, which is taken from the old village renovation project in Liuzhiyuan area of Jinan City, and the main components are waste concrete soil blocks and waste bricks , The brick-concrete ratio is about 7:3, the water absorption rate is 5.347%, the particle specific gravity is about 2.71, and the crushing value is between 38.01% and 38.25%. The construction waste in the mixture can act as a skeleton as a coarse aggregate, and the river sand as a fine particle can be used to fill th...

Embodiment 2

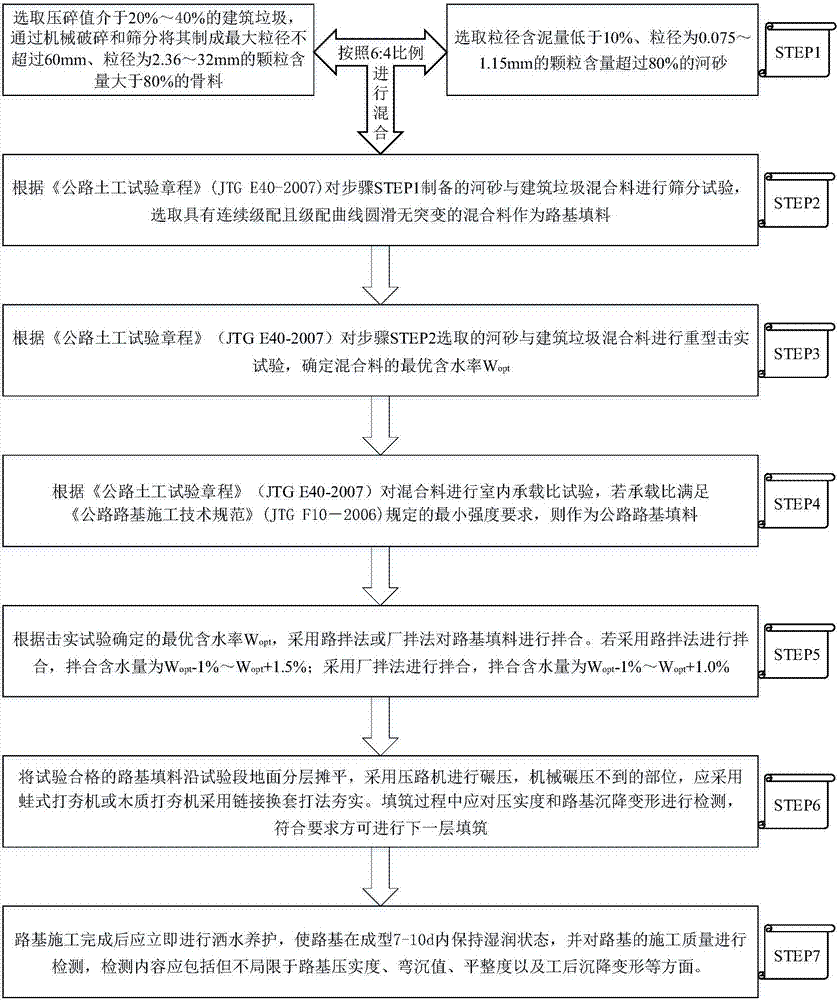

[0078] The present invention also provides a preparation method of roadbed filler produced from construction waste and river sand, the specific process is as follows: figure 1 As shown, the details are as follows:

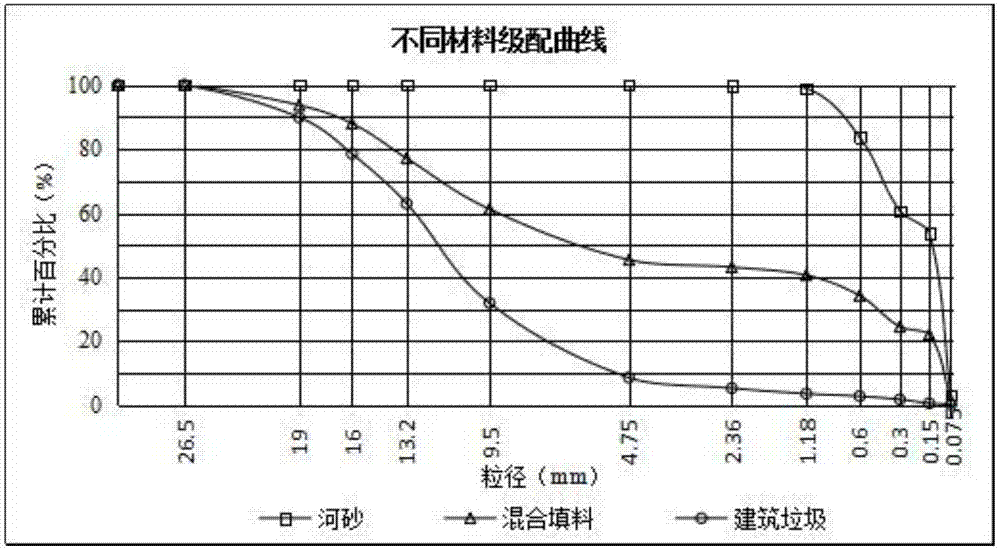

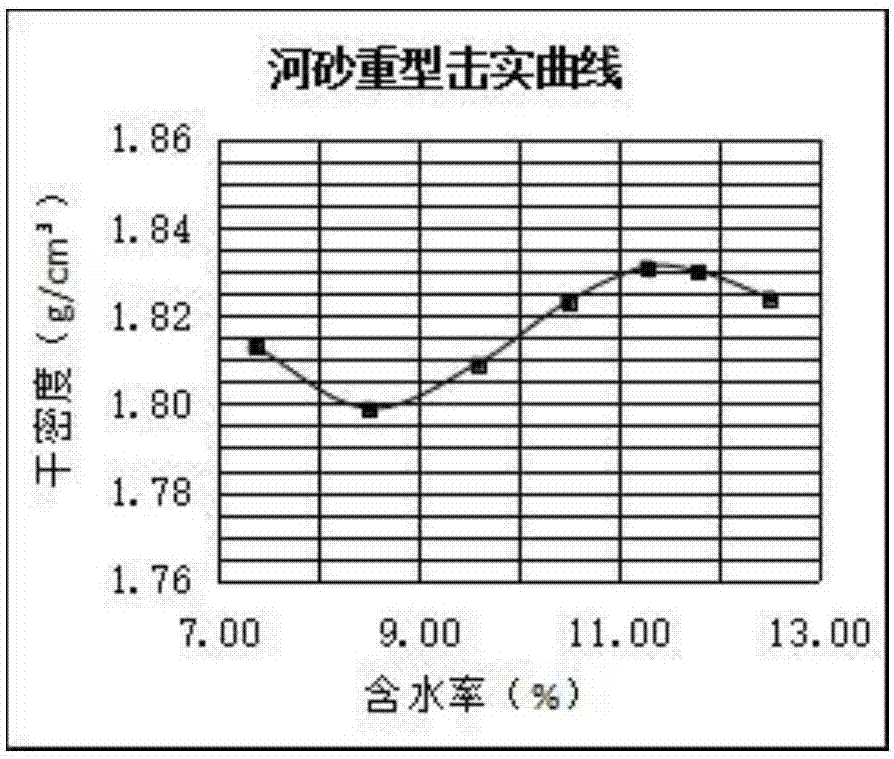

[0079] Step STEP1: The river sand selected in this example is taken from the Yellow River dam in the northwest of Jinan. It is a yellow-brown loose and non-sticky single-grain structure with a specific gravity of about 2.66 and a mud content of 3.25. The selected construction waste is taken from the Liuzhiyuan area of Jinan City The main components of the old village renovation project are waste concrete clods and waste bricks. The brick-to-concrete ratio is about 7:3, the particle proportion is about 2.71, and the crushing value is between 38.01% and 38.25%. attached by figure 2 It can be seen from the gradation curve shown that the particle content of river sand with a particle size between 0.075 and 1.18 mm exceeds 90%, the mud content is about 3.2%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com