Method for treating kitchen waste into fertilizers

A treatment method and kitchen waste technology, applied in botany equipment and methods, bio-organic part treatment, organic fertilizer, etc., can solve the problems of breeding mosquitoes and flies, odor, unreasonable use of livestock and poultry breeding waste, etc., and achieve improvement The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

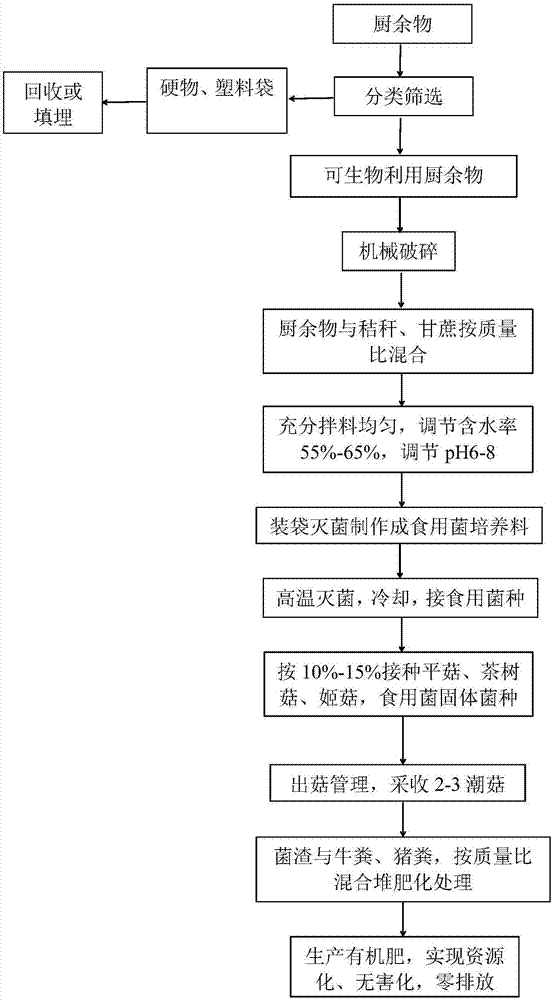

Image

Examples

Embodiment 1

[0025] Classify and screen the food waste to screen out non-bioavailable food waste, including bones, fruit cores, and plastic bags, to obtain bioavailable food waste, including food residues, fruit and vegetable residues, and The kitchen waste can be bioused for mechanical crushing, and it is ready for use.

[0026] Weigh 1 part of 50kg of bioavailable kitchen waste, 1 part of 50kg of straw powder and 1 part of 50kg of bagasse into the blender and mix them thoroughly. Adjust the water content of the culture medium after mixing to 55%-60%. Adjust the pH value to 6.5-7.5, mix well, divide into polypropylene plastic bags, place in a sterilizing pot, maintain a high temperature of 121°C, sterilize for 2 hours, and put it in a clean and sterile culture room to cool naturally for later use.

[0027] Purchase high-quality Pleurotus ostreatus cultivars from the market, inoculate them in a sterile inoculation room, place them in a clean and sterile cultivation room, cultivate bacteria...

Embodiment 2

[0034] The food waste is sorted and screened to obtain bioavailable food waste, including food and fruit and vegetable meals, and the bioavailable food is mechanically crushed for use.

[0035] The remaining non-biologically available kitchen products are screened out, and the recyclable parts are screened out, including bones and fruit cores, and the non-recyclable parts are landfilled, including plastic bags and lunch boxes.

[0036] Weigh 1 portion of 200kg of bioavailable kitchen waste, 1 portion of 200kg of straw powder and 1 portion of 200kg of bagasse into a blender and mix thoroughly, adjust the water content of the medium after mixing to 60% to 65%, add quicklime Adjust the pH value to 6-6.5, mix well, divide into polypropylene plastic bags, place in a sterilizing pot, sterilize at 121°C for 2 hours, and put them in a clean and sterile culture room to cool naturally for later use.

[0037] Inoculate high-quality mesophilic tea tree mushroom culture strains. Inoculate...

Embodiment 3

[0044] The food waste is sorted and screened to obtain bioavailable food waste, including food and fruit and vegetable meals, and the bioavailable food is mechanically crushed for use. The remaining non-biologically available kitchen products are screened out, and the recyclable parts are screened out, including bones and fruit cores, and the non-recyclable parts are landfilled, including plastic bags and lunch boxes.

[0045] Weigh 1 part of 500kg of bioavailable kitchen waste, 1 part of 500kg of straw powder and 1 part of 500kg of bagasse into the blender and mix thoroughly, adjust the water content of the mixed medium to 60%, add lime to adjust the pH value After 6-8 hours, mix well, divide into polypropylene plastic bags, place in a sterilizing pot, sterilize at 121°C for 2 hours, and put them in a clean and sterile culture room to cool naturally for later use.

[0046] Inoculate high-quality jitake mushroom culture strains. Inoculate under sterile conditions, manage bact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com