Anti-friction material based on FDM 3D printing, preparation method of anti-friction material and method for enhancing anti-friction property of product made of material

A kind of anti-friction material, 3D technology, applied in the field of 3D printing materials, can solve the problems such as the limitation of FDM application range, and achieve the effect of filling the gap in the market, high safety and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

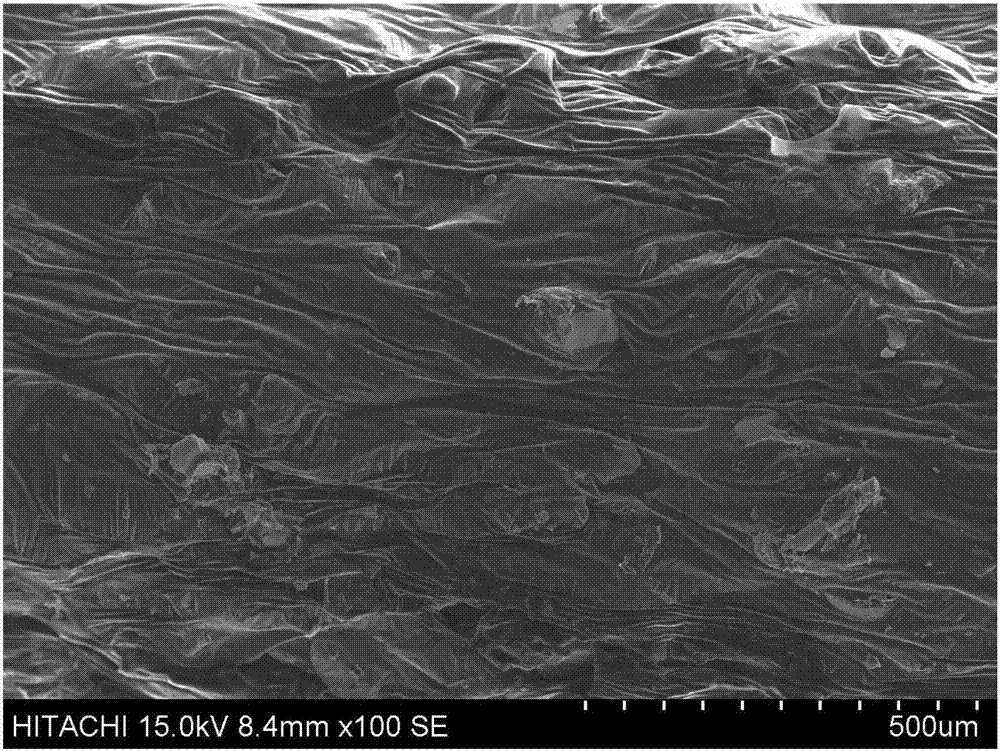

Image

Examples

Embodiment 1

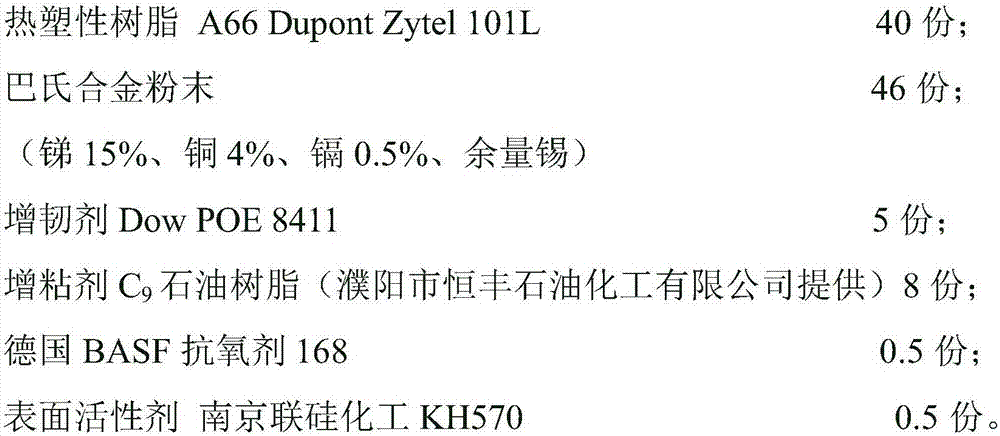

[0045] Proportioning according to following parts by weight:

[0046]

[0047] 2. Preparation method

[0048] 1) The raw materials are weighed in proportion;

[0049] 2) Ball mill the PA66 pellets in a liquid nitrogen environment for 1 hour to obtain a powder with a particle size of about 200 μm; at the same time, disperse the silane coupling agent KH570 in the Babbitt alloy powder;

[0050] 3) Put the above components into a high-speed mixer and stir for 10 minutes at high speed, and mix thoroughly;

[0051] 4) Put the mixture obtained after fully mixing in step 3) into a HAAKE twin-screw extruder for plasticization and extrusion, and use a pelletizer to granulate. The process conditions are shown in Table 1.

[0052] Table 1

[0053] TS1 / ℃

TS2 / ℃

TS3 / ℃

TS4 / ℃

TS5 / ℃

TS6 / ℃

FR / %

n / r / min

220

230

245

245

230

220

7

50

[0054] 5) Put the finished pellets into a single-screw extruder for drawing and winding, an...

Embodiment 2

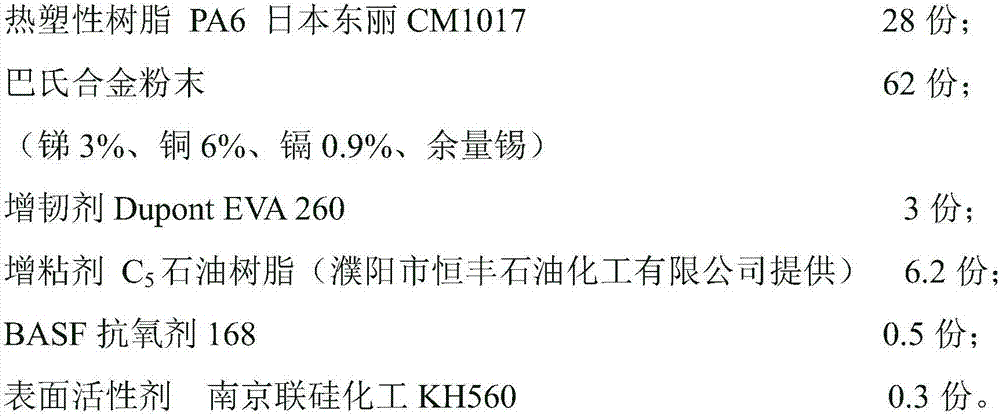

[0058] 1. According to the following proportions by weight:

[0059]

[0060] 2. Preparation method

[0061] 1) Weigh the raw materials in proportion;

[0062] 2) Ball mill the PA6 pellets for 1 hour in a liquid nitrogen environment to obtain a powder with a particle size of about 200 μm; at the same time, disperse the silane coupling agent KH560 in the Babbitt alloy powder;

[0063] 3) Put the above components into a high-speed mixer and stir at high speed for 10 minutes, and mix thoroughly;

[0064] 4) Put the mixture obtained after fully mixing in step 3) into a HAAKE twin-screw extruder for plasticizing and extruding, and use a pelletizer to granulate. The process conditions are shown in Table 3.

[0065] table 3

[0066] TS1 / ℃

TS2 / ℃

TS3 / ℃

TS4 / ℃

TS5 / ℃

TS6 / ℃

FR / %

n / r / min

225

235

250

245

235

230

7

50

[0067] 5) Put the finished pellets into a single-screw extruder for drawing and winding, and the di...

Embodiment 3

[0071] 1. According to the following proportions by weight:

[0072]

[0073] 2. Preparation method

[0074] 1) Weigh the raw materials in proportion;

[0075] 2) Ball mill the ABS pellets in a liquid nitrogen environment for 1 hour to obtain a powder with a particle size of about 200 μm; at the same time, disperse the silane coupling agent KH560 in the Babbitt alloy powder;

[0076] 3) Put the above components into a high-speed mixer and stir for 10 minutes at high speed, and repeat the mixing;

[0077] 4) Put the mixture obtained after fully mixing in step 3) into a HAAKE twin-screw extruder for plasticizing and extruding and use a pelletizer to granulate. The process conditions are shown in Table 5:

[0078] table 5

[0079] TS1 / ℃

TS2 / ℃

TS3 / ℃

TS4 / ℃

TS5 / ℃

TS6 / ℃

FR / %

n / r / min

185

195

205

205

190

180

7

50

[0080] 5) Put the finished pellets into a single-screw extruder for drawing and winding, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com