A method of generating anti-friction porous structure repair coating

A porous structure and coating technology, which is applied in the field of generating anti-friction porous structure repair coatings, can solve the problems of unpopularity, and achieve the effect of easy operation, fast speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

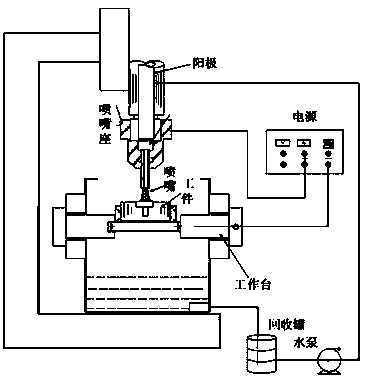

[0045] The operation steps are as follows:

[0046] 1. For the surface treatment of the workpiece, grinding, degreasing, passivation, washing and drying are carried out in sequence.

[0047] 2. Configure the electrolyte. The composition and process parameters of the electrolyte in the present embodiment are respectively:

[0048] CuSO 4 ·5H 2 O 250g / L, 98% concentrated sulfuric acid 50g / L, electrolyte temperature is 25°C. The electrolyte solution is prepared with analytical pure or chemical pure reagents plus distilled water.

[0049] 3. Place the workpiece in the deposition tank, and align the nozzle to the corresponding position of the wear.

[0050] 4. The selection of process parameters is a rectangular nozzle diameter of 10×1mm, and the distance between the nozzle and the substrate is 5mm;

[0051] Electrolyte flow rate 300L / h, machine tool scanning speed 1000mm / min;

[0052] Pulse current, peak density 450A / dm 2 , the duty ratio is 1:5, and the pulse frequency is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com