Universal wheel near bit stabilizer

A universal wheel and stabilizer technology, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of short service life, increased drilling costs, severe vibration of drill pipes, etc., to facilitate running in and out, and improve The effect of drilling efficiency and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention:

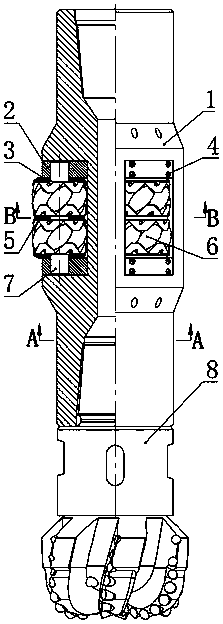

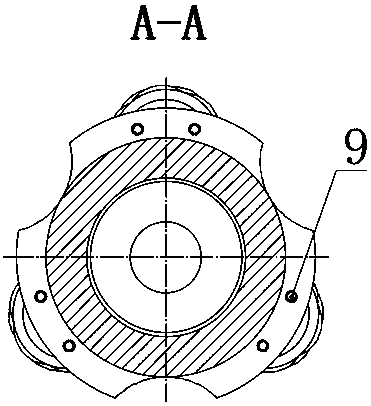

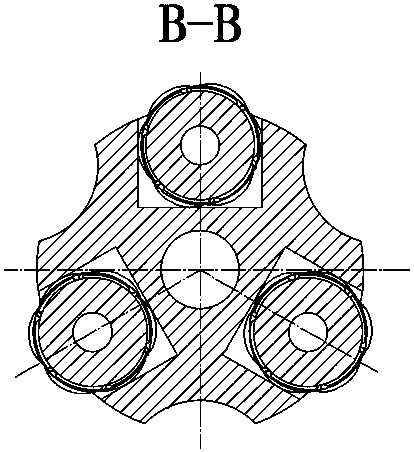

[0021] Referring to the accompanying drawings, the universal wheel type stabilizer near the drill bit is composed of a body 1, a drill bit 8, and a universal wheel mechanism. The universal wheel mechanism includes a support 2, an outer wheel 3, an inner hexagonal screw a4, an intermediate wheel 5, Universal wheel 6, shaft 7, inner hexagonal screw b9, outer wheel 3, universal wheel 6, intermediate wheel 5, universal wheel 6 and outer wheel 3 are placed in sequence on the axis 7, and the two ends of the axis 7 are placed in the support 2, Then install the universal wheel mechanism in the groove evenly distributed in the outer circumferential direction of the body 1 through screws, radially fix the support 2 in the groove of the body 1 through the hexagon socket screw a4, and axiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com