Full-automatic material taking device

A reclaiming device, fully automatic technology, applied in sewing machine control devices, textiles and papermaking, sewing equipment, etc., can solve problems affecting processing quality, fabric stretching, fabric shrinkage and wrinkles, etc. Accurate positioning of materials and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

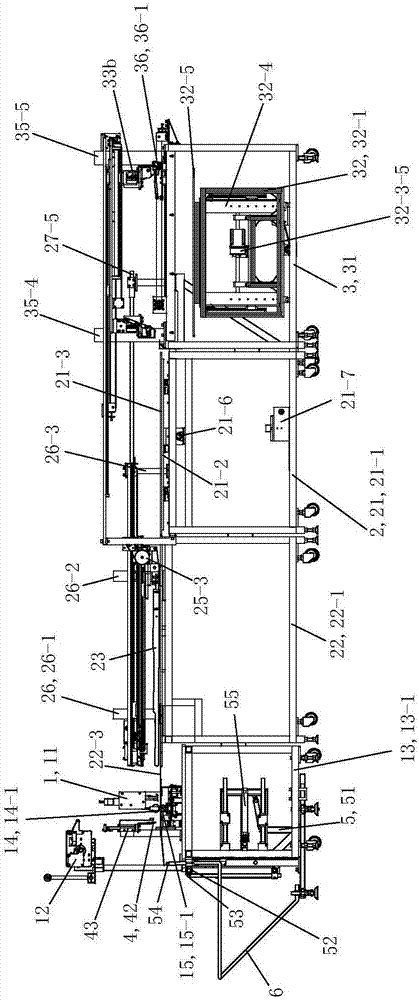

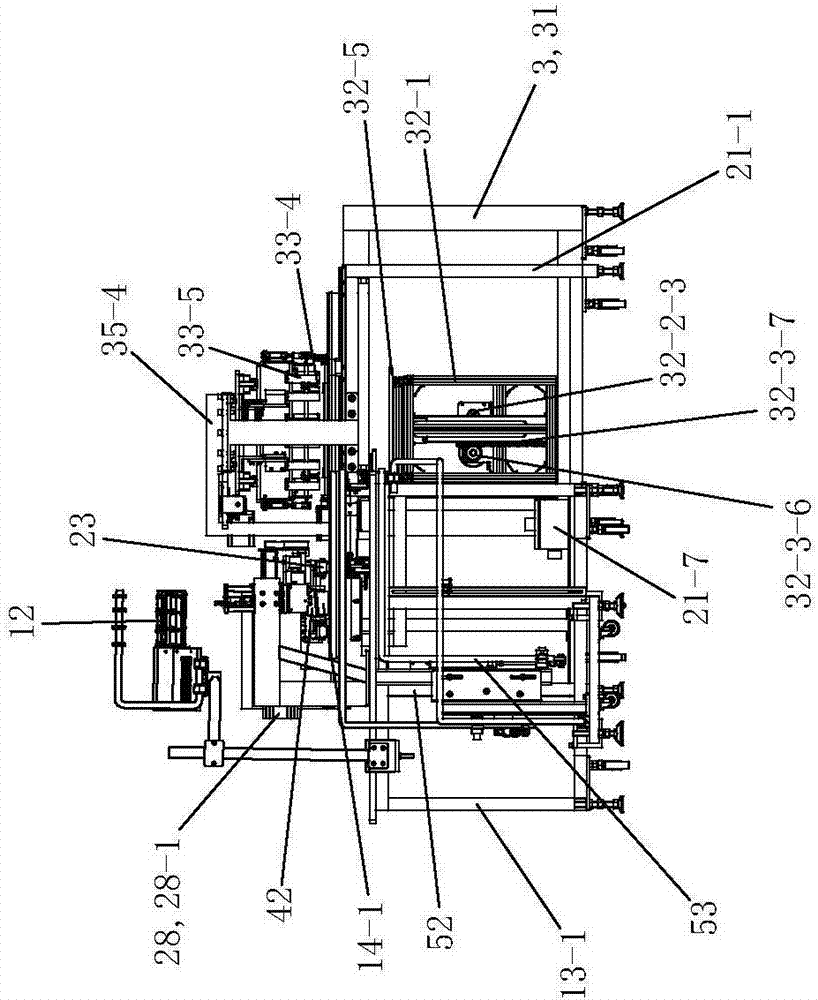

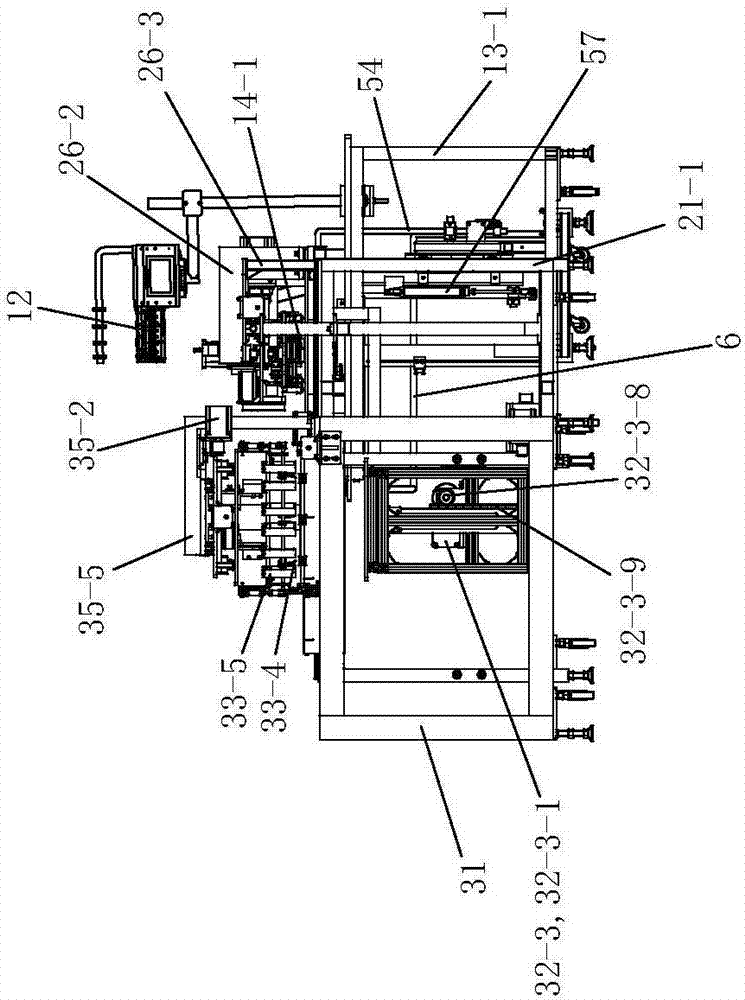

[0074] See Figure 1 to Figure 8 with Figure 21 to Figure 26 , the fully automatic retrieving device 3 for multi-strip sewing equipment of the present invention includes a main frame body 31, a lifting platform assembly 32, a first retrieving mechanism 33a, a second retrieving mechanism 33b, and a retrieving mechanism adjustment assembly 34 , The reclaiming driving assembly 35 and the platen assembly 36.

[0075] See Figure 1 to Figure 8 with Figure 21 to Figure 26 , The lower side of the main frame body 31 is provided with corresponding casters for easy movement.

[0076] Figure 21 to Figure 25 , The lifting platform assembly 32 includes the lifting platform main frame body 32-1, the lifting platform front and rear driving components 32-2, the lifting platform up and down driving components 32-3, the lifting frame 32-4 and the material placement plate 32-5. The front and rear driving components 32-2 of the lifting platform drive the main frame body 32-1 of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com