Locking type damping steel rail iron sheet composite structure

A technology of combined structure and iron backing plate is applied in the field of rail fasteners, which can solve the problems of easy vibration, poor stability, and high noise, and achieve the effects of reducing collision, reducing vibration and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

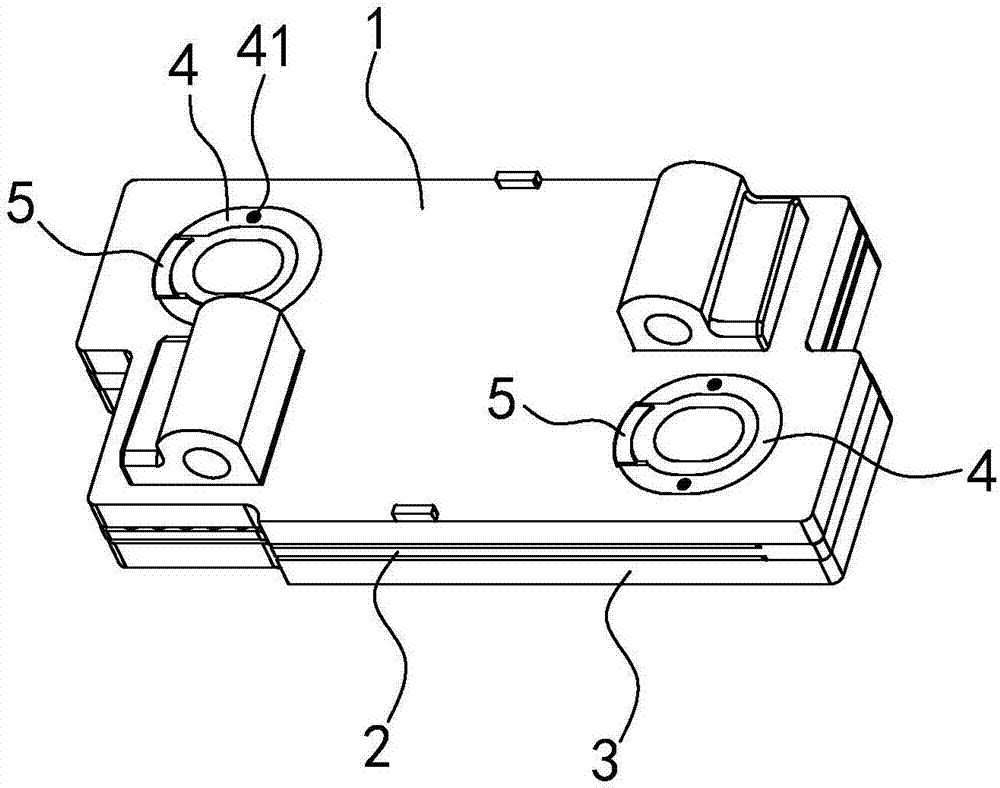

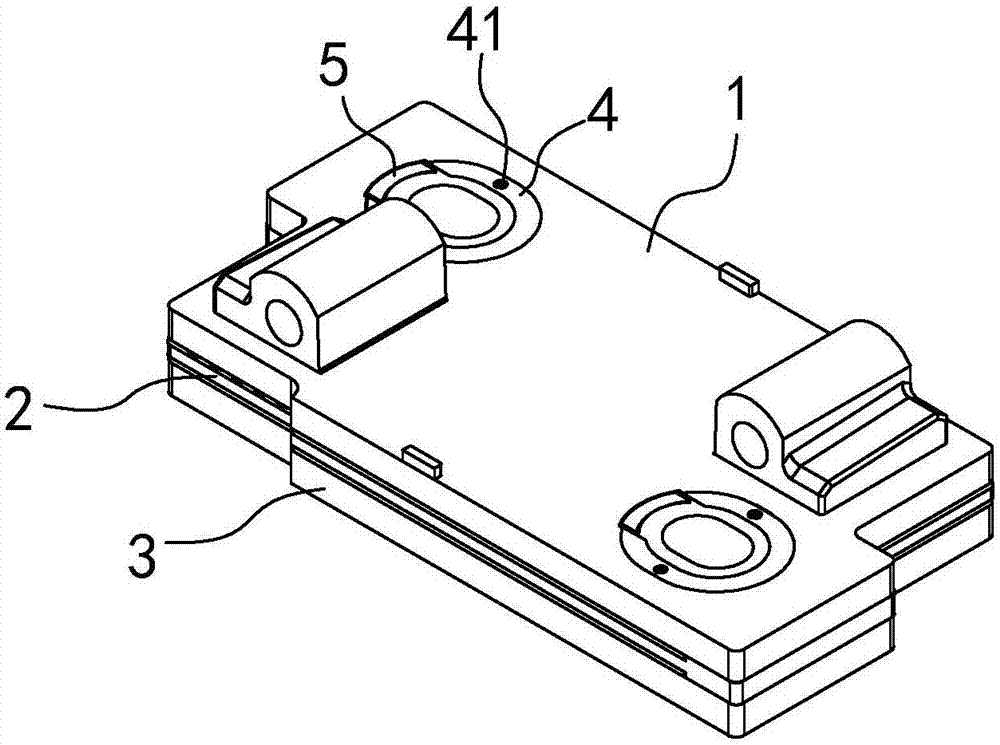

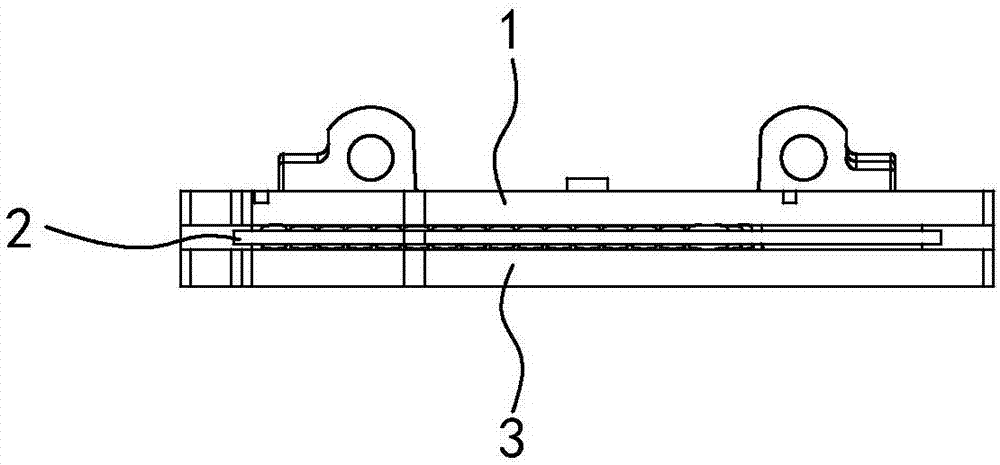

[0047] Embodiment: Combination structure of lock-type damping rail and iron backing plate

[0048] See attached Figure 1-4 , including an upper iron backing plate 1, an elastic backing plate 2, a lower iron backing plate 3 and a locking sleeve structure, the upper iron backing plate 1 is located above the lower iron backing plate 2, and the elastic backing plate 2 is clamped on the upper iron backing plate Between the backing plate 1 and the lower iron backing plate 3, the locking sleeve structure is used to lock the upper iron backing plate 1, the elastic backing plate 2 and the lower iron backing plate 3.

[0049] See attached Figure 5-8 , wherein, the upper iron backing plate 1 is a first plate-shaped structure, in this embodiment, the first plate-shaped structure adopts a rectangular plate-shaped structure, and the plate surface of the first plate-shaped structure has a center line or a line of symmetry , two first through holes 10 are provided on the first plate-like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com