Steel frame lightweight sandwich plate integrated wall and construction method thereof

A sandwich panel, steel frame technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of processing and construction difficulties, and achieve the effect of fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

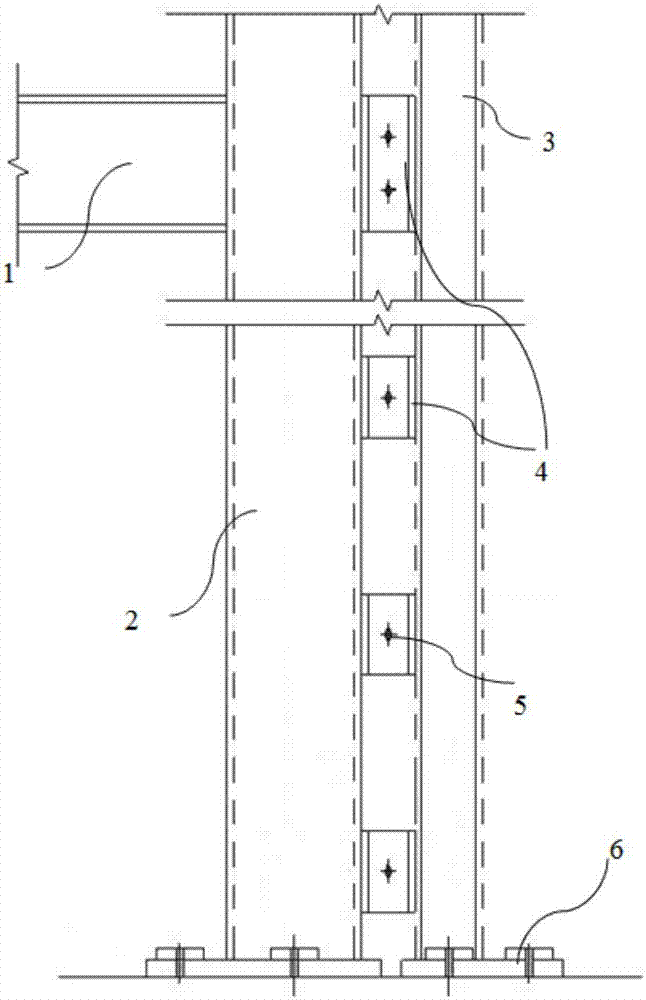

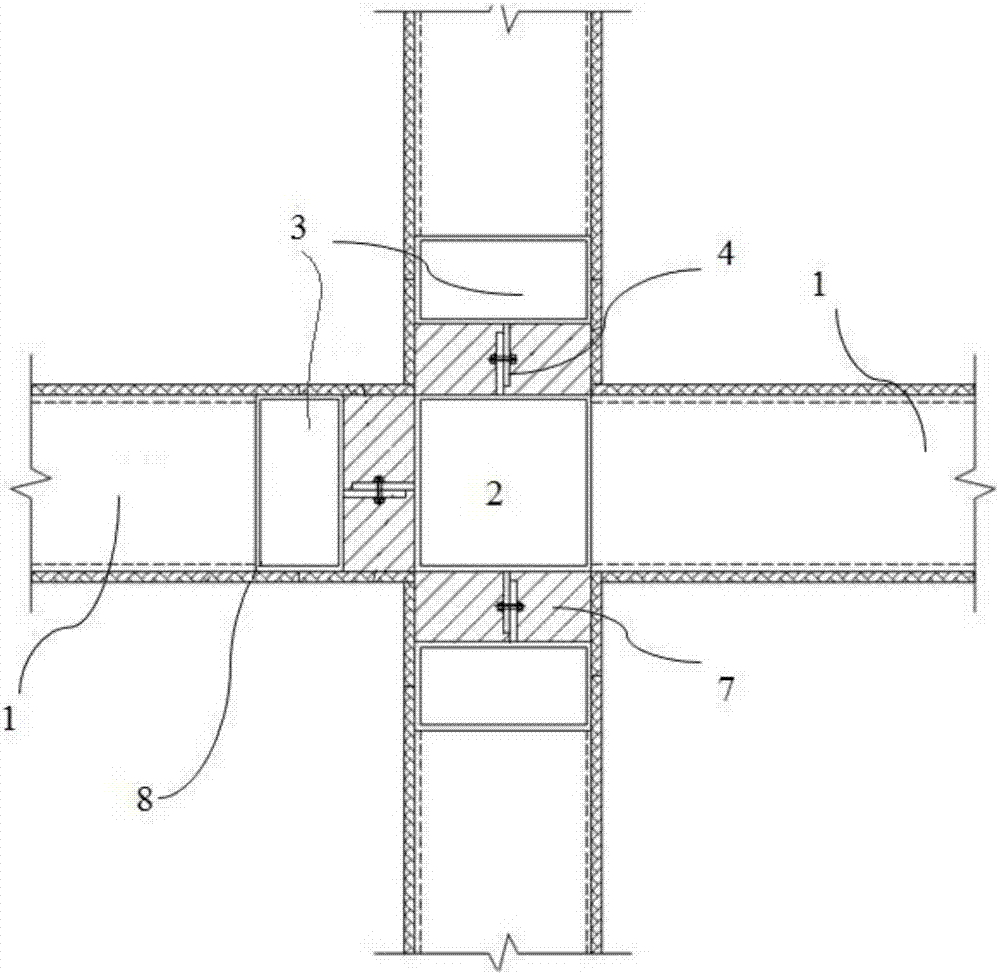

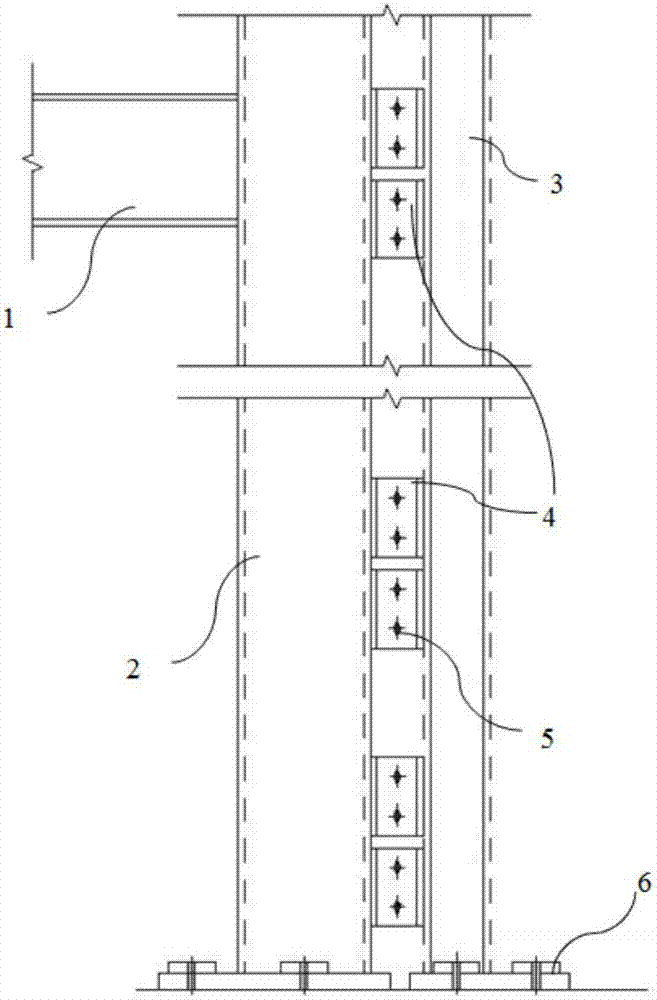

[0054] Firstly, in the present invention, the adjacent wall connection structure of the integrated wall designed for how to realize the connection and fixation of adjacent integrated walls is introduced. The present invention improves the traditional overall frame structure into a plurality of unit frame structures combined with beam columns, and the connection structure between columns is divided into two types: single-row panel and double-row panel.

[0055] Such as figure 1 and 2As shown, it is a connection structure in the form of a single row of panels. In the adjacent wall, a steel column 2 of one integrated wall is used as the central load-bearing column, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com