Lithium battery pole piece slitting burr detector

A detection device, lithium battery technology, applied in the direction of measuring devices, optical devices, optical testing flaws/defects, etc., can solve problems such as easy to pierce the diaphragm, excessive self-discharge, easy to generate burrs, etc., to improve product quality, The effect of controlling the size of burr on the cut and avoiding internal short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Further description will be made below in conjunction with drawings and embodiments.

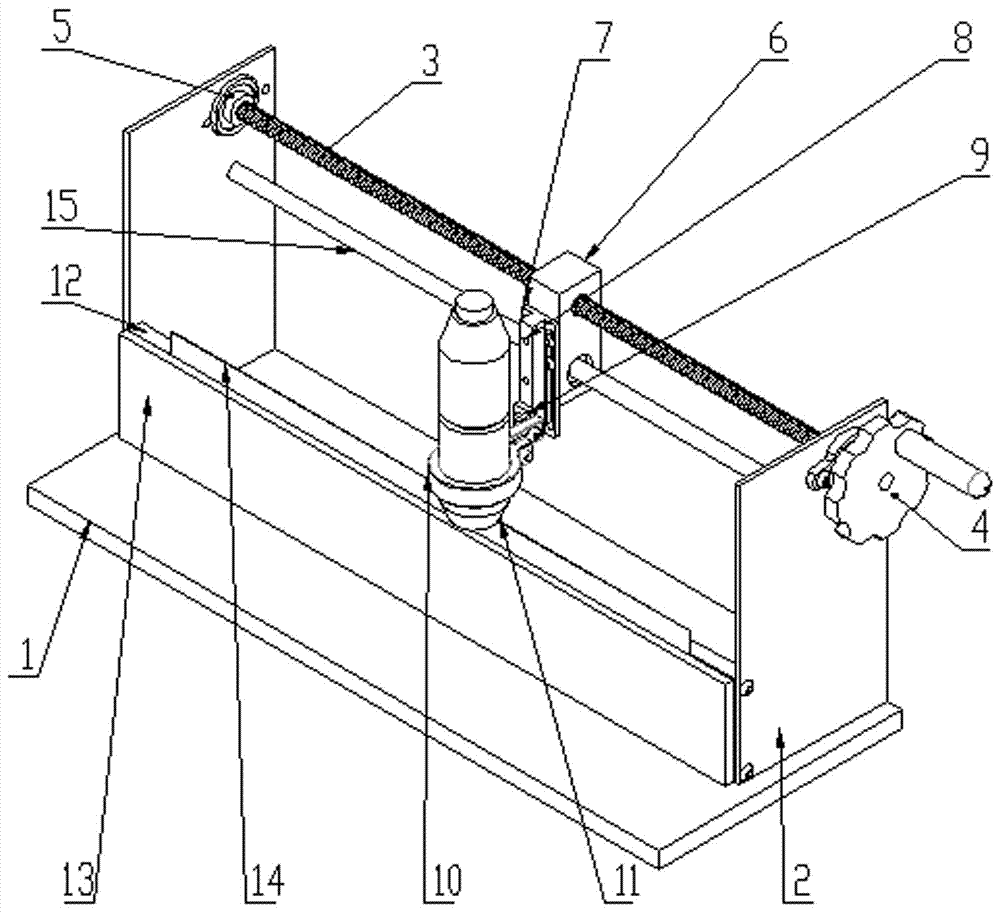

[0011] figure 1 As shown: a lithium battery pole piece cutting burr detection device includes a base plate 1, a side bracket 2, a hand wheel 4, a screw 3, a screw nut, a transition frame 6, a guide post 15, a sliding bearing, and an up and down adjustment bracket 7, The fixed ring 10, the microscope 11 and the splint group, the bottom plate 1 passes through the side brackets 2 on both sides and passes through the bearing seat 5 to connect the screw rod 3, one end of the screw rod 3 passes through the side bracket to connect to the handwheel 4, and the thread on the screw rod is screwed. The rod nut and the screw nut are fixedly connected in the transition frame 6. The guide post 15 is parallel to the screw rod 3 and connected on the side brackets on both sides of the bottom plate. The guide post 15 is connected to the transition frame 6 through the sliding bearing. The transition fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com