A standardized automatic sample preparation machine for geotechnical samples

An automatic manufacturing and prototyping technology, which is applied in the direction of analyzing materials and instruments, can solve the problems of increased pore water pressure inside the soil sample, uneven surface of the sample, and difficulty in reaching the expected density, so as to improve the effective use rate and sample The effect of uniform density and shortened sample preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

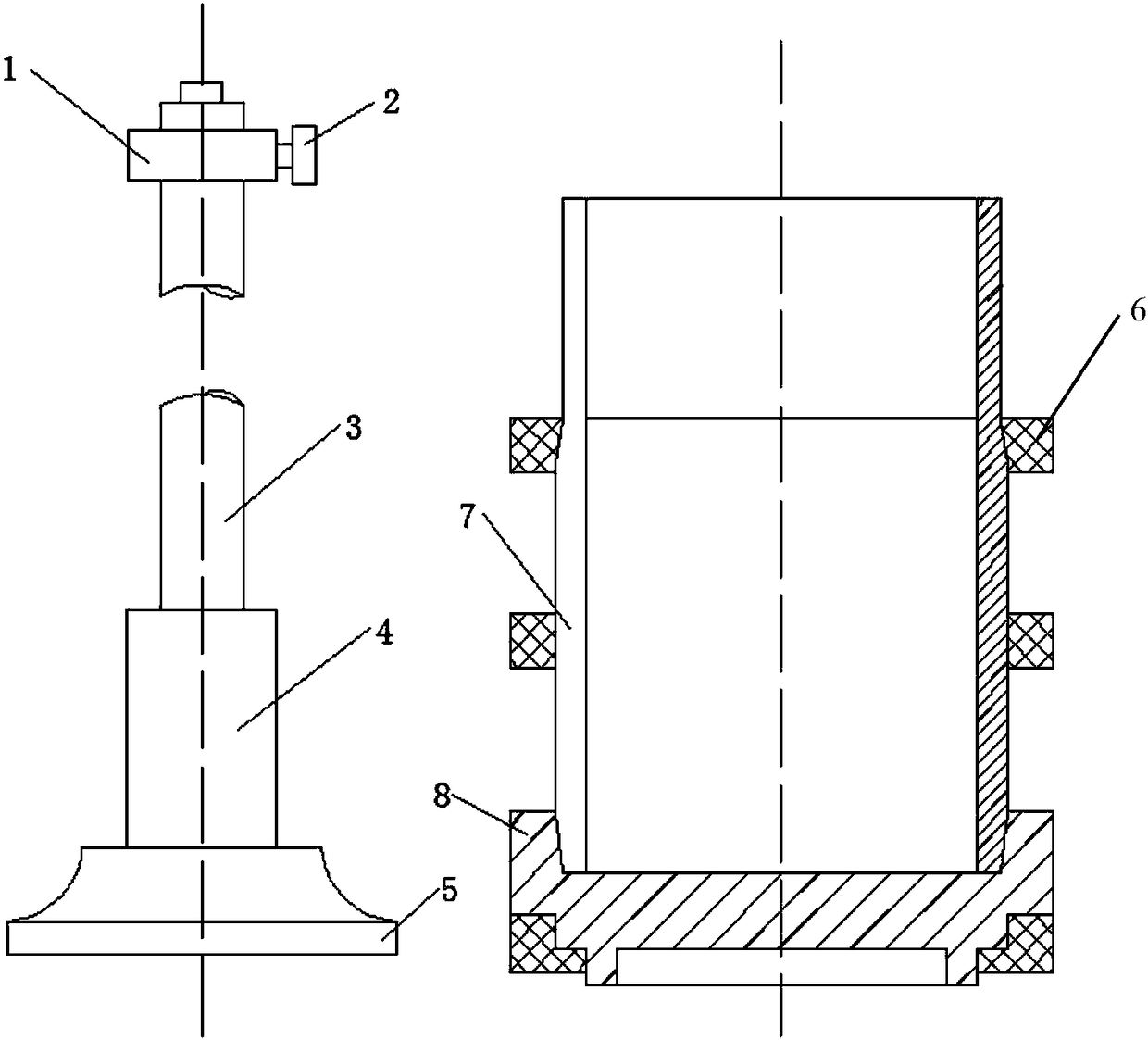

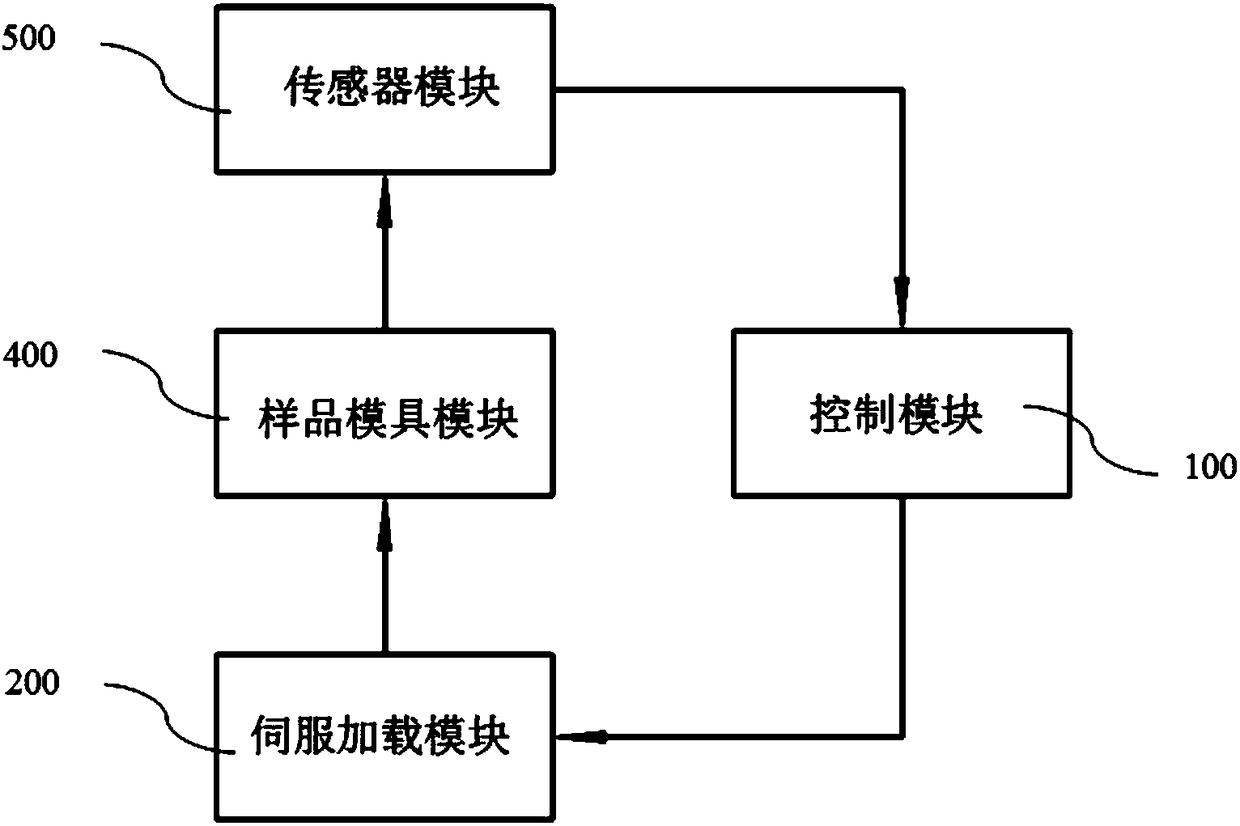

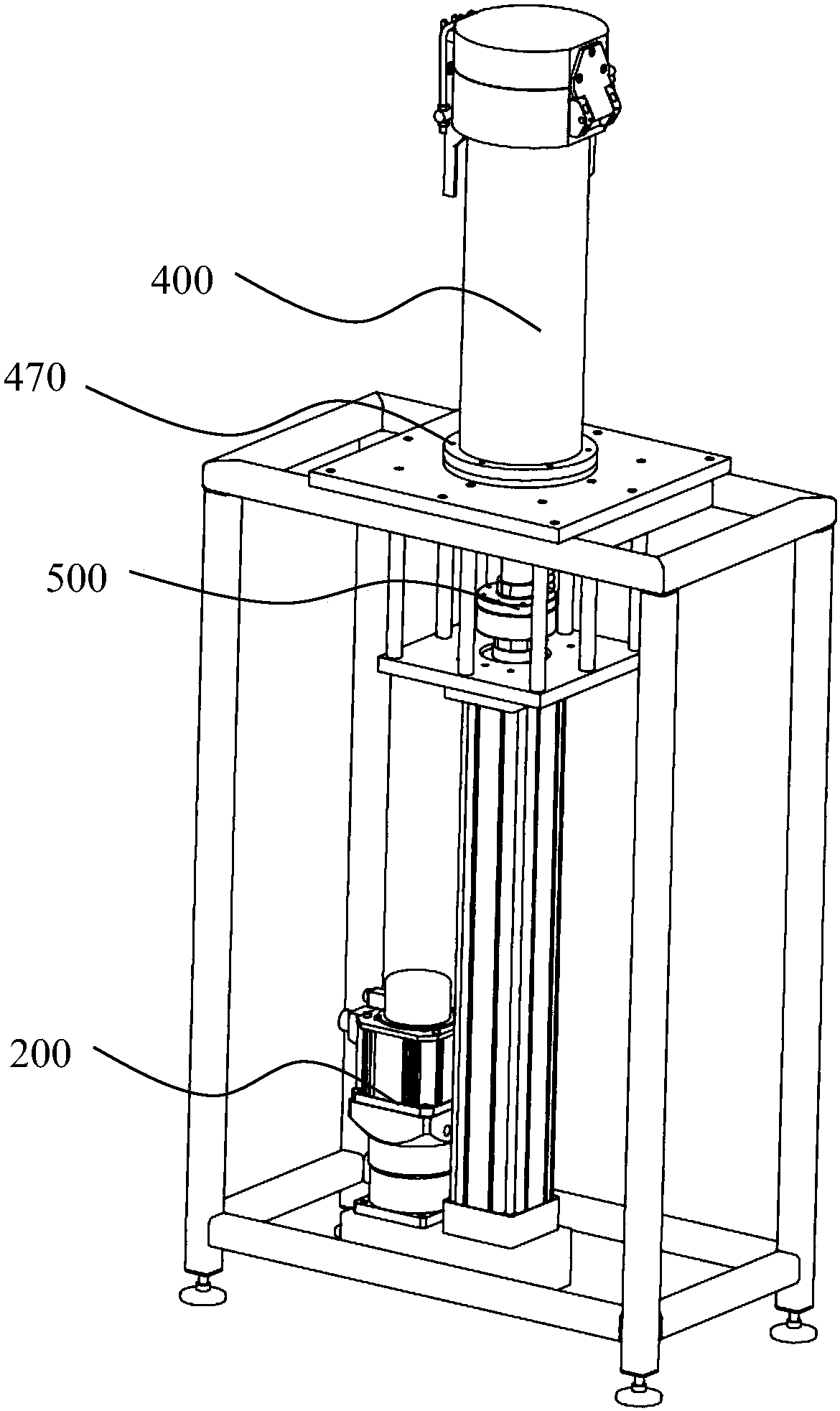

[0077] Such as Figures 2 to 5 As shown, a standardized automatic sample preparation machine for geotechnical samples includes: a control module 100 , a servo loading module 200 , a sample mold module 400 , a sensor module 500 , and an upper exhaust and liquid discharge pot 600 and a lower exhaust and liquid discharge pot 700 .

[0078] The control module 100 includes a control terminal 110 and a servo controller 120 connected to the control terminal 110 . Preferably, the control terminal 110 can be a computer, a notebook computer, a tablet computer, a smart phone and the like.

[0079] The servo loading module 200 is controlled by the control module 100 and includes a piston assembly 300 .

[0080] In this embodiment, the servo loading module 200 includes a servo motor 210 connected to the servo controller 120, a reduction mechanism (such as a reduction box) 220 connected to the servo motor 210, a transmission case 230 connected to the reduction mechanism 220, and The linea...

Embodiment 2

[0117] The main difference between this embodiment and embodiment 1 is:

[0118] The servo loading module 200 includes a servo motor 210 connected to the servo controller 120, a reduction mechanism 220 connected to the servo motor 210, a transmission box 230 connected to the reduction mechanism 220, and a hydraulic telescopic device connected to the transmission box 230; The expansion rod of the hydraulic expansion device is connected with the piston assembly 300 through a universal joint 242 .

[0119] All the other parts are identical with embodiment 1.

Embodiment 3

[0121] This embodiment also provides a standardized automatic sample preparation machine for geotechnical samples. It includes a control module as described in Embodiment 1 to 3 and a plurality of sets of servo loading modules as described in Embodiment 1 to 2, sample mold module, sensor module, upper exhaust and liquid discharge pot and lower exhaust discharge The controlled module composed of liquid jugs.

[0122] The standardized automatic sample preparation machine for geotechnical samples in this embodiment has multiple sets of loading systems, and the sample preparation molds of each system can be replaced according to different sample size requirements, so as to meet the requirements for making samples of various sizes.

[0123] For example, the standardized automatic sample preparation machine for geotechnical samples in this embodiment can be managed by one set of control system and realized by three sets of execution systems, which can respectively produce four speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com