Stable food-grade low-fat lard-based oil-in-water emulsion and preparation thereof

An oil-in-water emulsion, food-grade technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems affecting the appearance and taste of the product, and achieve the effect of avoiding excessive intake of fat, small particles and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

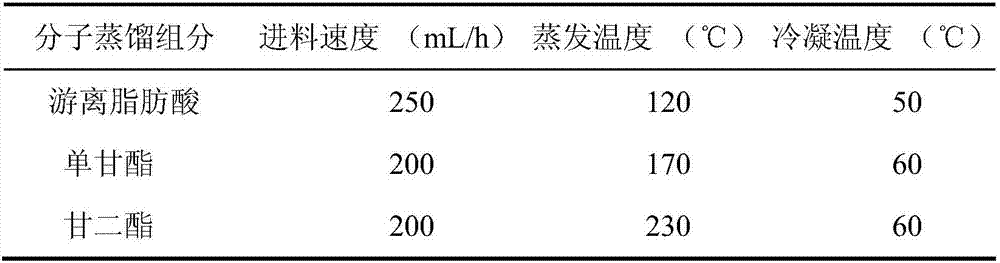

Method used

Image

Examples

Embodiment 1

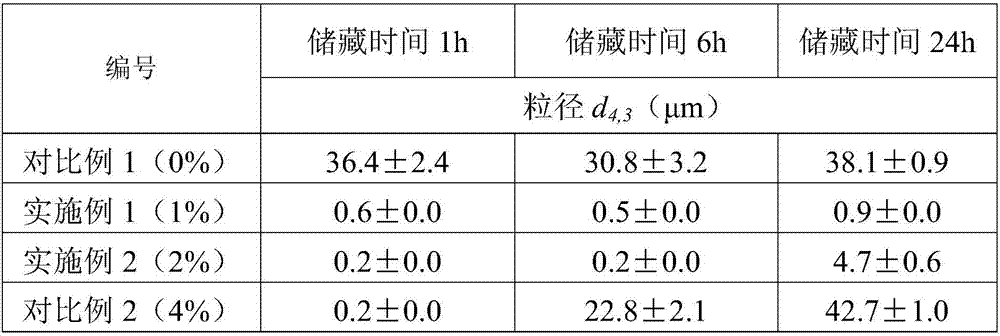

[0033] A stable food-grade low-fat lard-based oil-in-water emulsion is composed of 5g lard, 1g lard-based monoglyceride, 4g lard-based diglyceride, 1g sodium caseinate and 89g distilled water, wherein lard The concentration of monoglyceride in the emulsion is 1.0wt.%, the lard content is 5.0wt.%, and the total fat content is 10wt.%.

[0034] The preparation method of lard base oil-in-water emulsion in the present embodiment is:

[0035] (1) Sodium caseinate was added to distilled water, and magnetically stirred at 70°C for 2 hours to obtain the aqueous phase of the emulsion;

[0036] (2) Heat lard, lard-based monoglyceride and lard-based diglyceride at 60°C for 30 minutes until completely melted, then add them to the water phase in step (1) in sequence, and vortex at 2500r / min 30s, 12600r / min high-speed shearing for 5min, rapidly cooled to room temperature and then stored to obtain a food-grade low-fat lard-based oil-in-water emulsion.

[0037] The food-grade low-fat lard-ba...

Embodiment 2

[0039] A stable food-grade low-fat lard-based oil-in-water emulsion, which is composed of 5g lard, 2g lard-based monoglyceride, 3g lard-based diglyceride, 1g sodium caseinate and 89g distilled water, wherein lard The concentration of monoglyceride in the emulsion is 2wt.%, the lard content is 5.0wt.%, and the total fat content is 10wt.%. The preparation method of the food-grade low-fat lard-based oil-in-water emulsion in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com