Novel mixing machine dust collection device

A technology of dust collection device and mixer, which is applied in the direction of mixer, mixer accessories, transportation and packaging, etc. It can solve the problems of uneven mixing, easy occurrence of clogging of casting machine and dust collection port, etc., achieves fast and uniform mixing, and avoids knots blocks, reducing the number of downtime for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

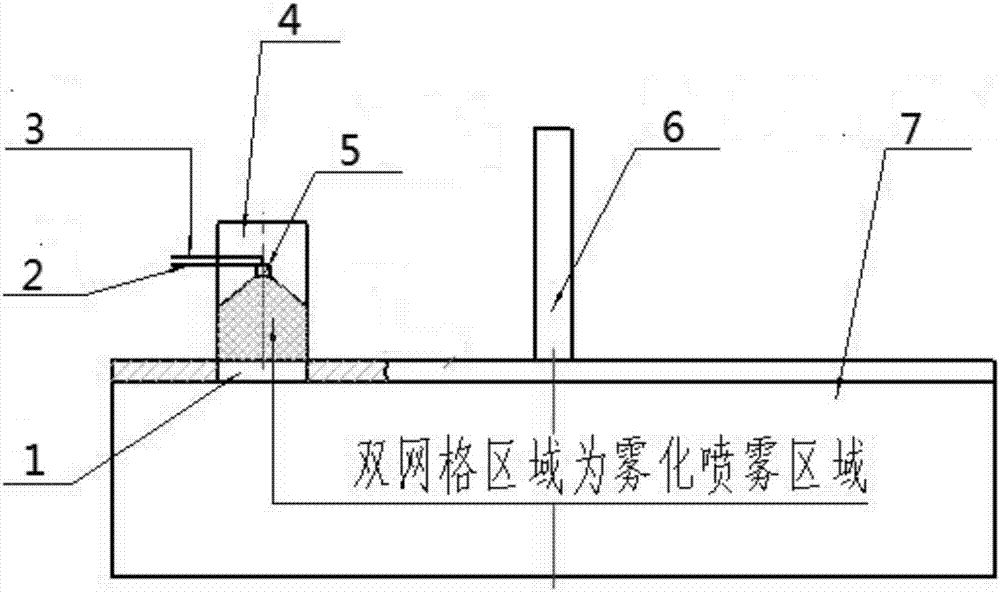

[0019] Such as figure 1 As shown, a new type of mixer dust collection device includes a mixer 7 and a dust collection device 4. The mixer 7 is connected to the motor through the mixer main shaft 6 arranged at the upper central axis, and the upper end surface of the mixer 7 is provided with a dust collector. hole 1, the dust collection device 4 is seamlessly connected with the dust collection hole 1 of the mixer 7, the dust collection device 4 includes a casing and a self-suction nozzle 5, and the self-suction nozzle 5 is installed in the upper middle of the casing, and the dust collection device 4 The upper end of the housing is provided with an air inlet and a water inlet, and the self-priming nozzle 5 communicates with the air inlet pipe 2 and the water inlet pipe 3 passing through the air inlet and the water inlet respectively.

[0020] The shell of the dust collecting device 4 is set as a hollow polytetrafluoroethylene tube, and the polytetrafluoroethylene tube is finely g...

Embodiment 2

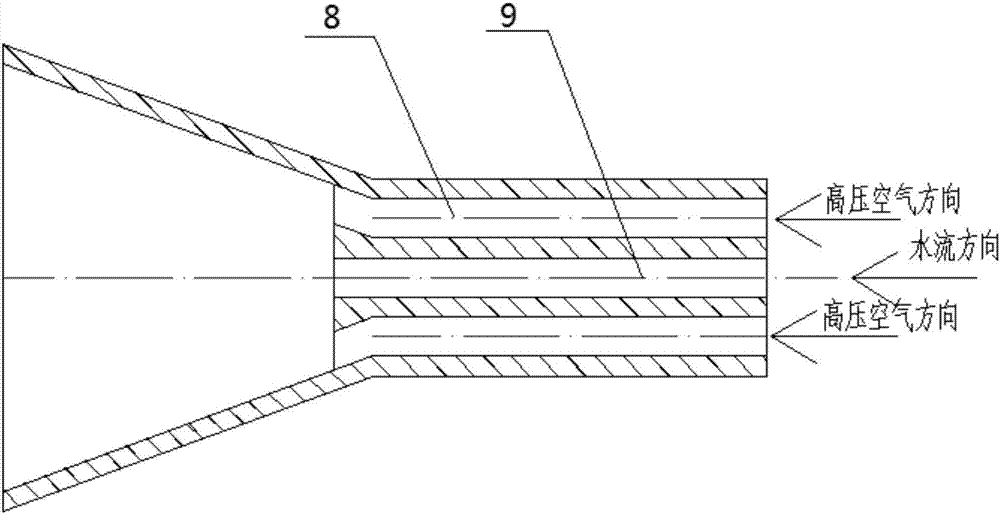

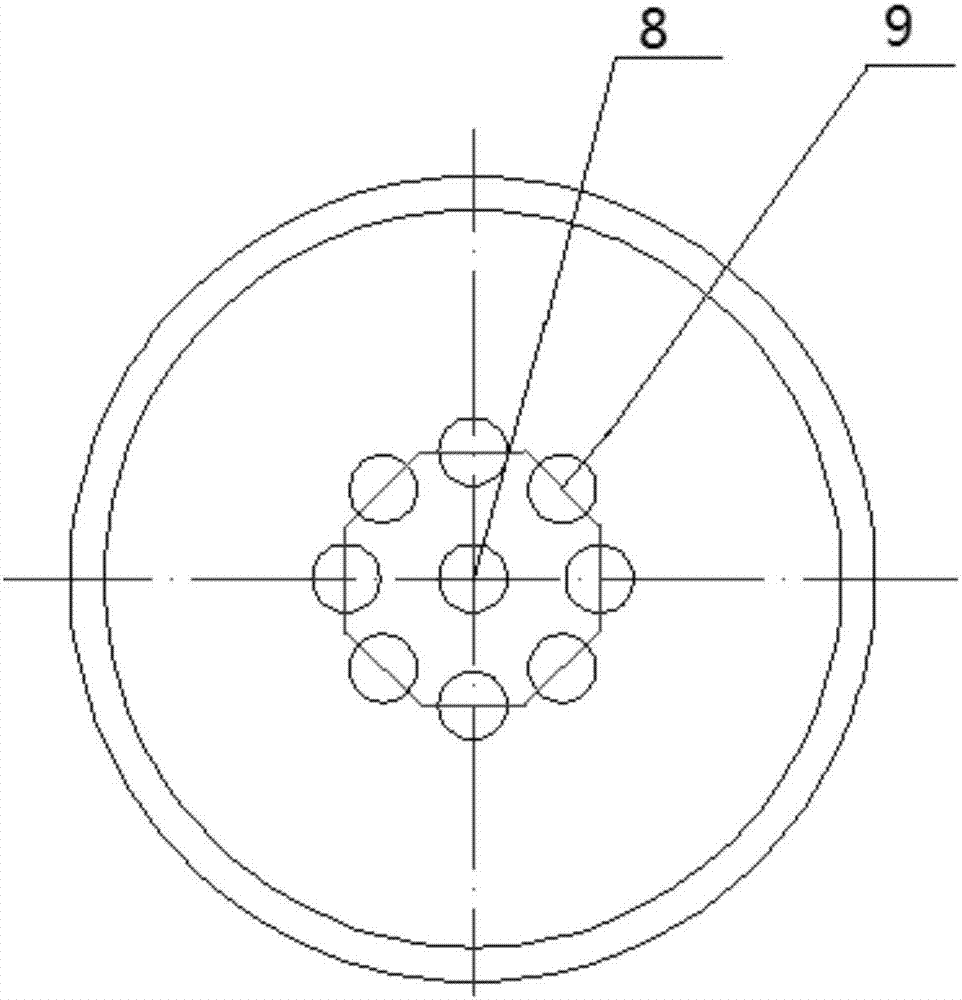

[0023] On the basis of Example 1, different from Example 1, such as figure 2 and image 3 As shown, a novel mixer dust collection device includes a self-priming nozzle 5, the self-priming nozzle 5 is set to an inverted funnel-shaped structure, and the center of the spray end of the self-priming nozzle 5 is provided with a water flow channel 8, so as to The water flow channel 8 is provided with an air flow channel 9 in a circular shape at the center of the circle, and the adjacent air flow channels 9 have the same diameter and are arranged at equal intervals. When the self-priming nozzle 5 is running, the high-pressure air enters the airflow channel 9 through the inlet pipe 2, and the water flow enters the water flow channel 8 through the water inlet pipe 3. At the same time, the airflow and water flow collide during the spraying process, which increases the atomization of the spray liquid. The degree, thereby increasing its contact area with the slurry, has the effect of uni...

Embodiment 3

[0025] On the basis of Example 1, different from Example 1, a new type of mixer dust collection device includes a self-priming nozzle 5, the upper end of which is set as a sawtooth-shaped disc around, self-priming The middle part of the spray head 5 is set as a hollow conical nozzle hole which successively decreases in step shape, and the lower end of the self-priming spray head 5 is set with a hollow spherical structure. The hollow sphere structure is beneficial to store liquid and provide a certain pressure for the spraying of liquid. The special structure of the nozzle hole makes the liquid spread outward along the stepped circular platform. As the flow channel of the water flow narrows progressively, the pressure of the water flow increases. , to facilitate the formation of water mist, and at the same time, prevent the slurry outside the self-priming nozzle 5 from flowing back into the nozzle to cause blockage, and improve the dust collection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com