A kind of stripping method of polyvinyl alcohol optical film

A polyvinyl alcohol-based, optical film technology, applied in chemical instruments and methods, lamination, lamination auxiliary operations, etc., can solve problems such as affecting the quality of the film, difficult to peel off, etc., to achieve good optical performance, fewer defects, The effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

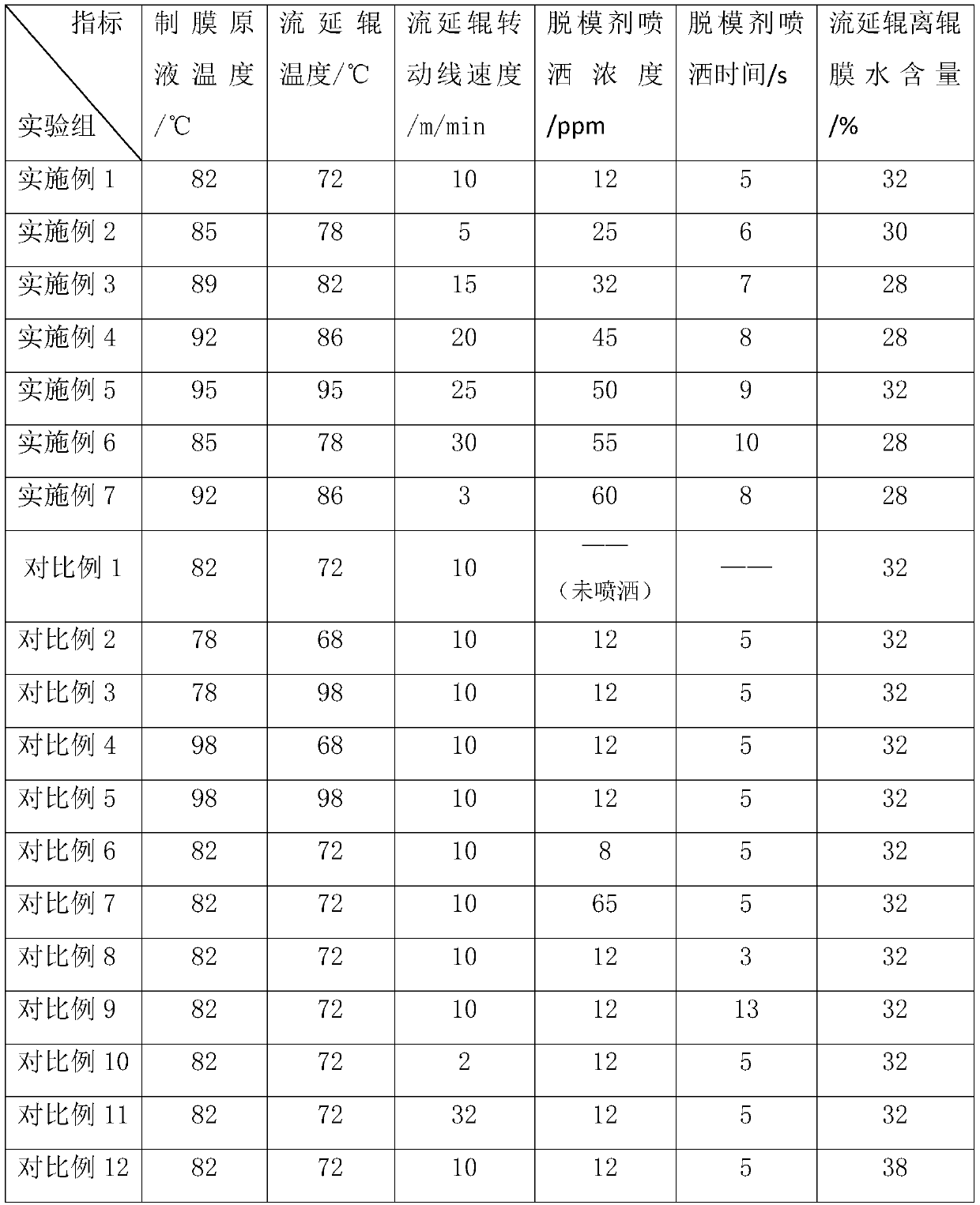

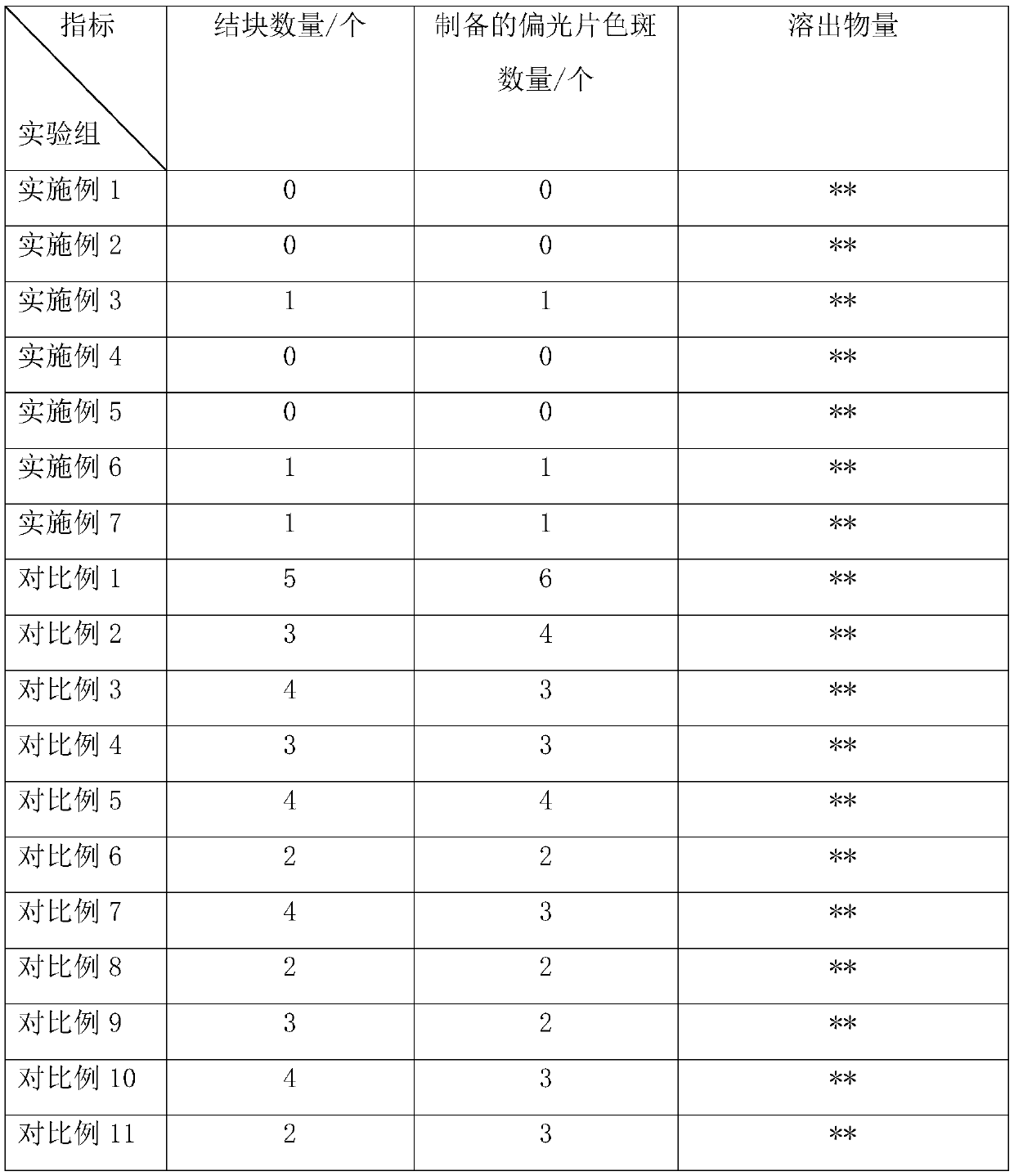

[0019] The invention discloses a peeling method of a polyvinyl alcohol-based optical film, which mainly includes the following steps:

[0020] (1) Each roll of optical film is sprayed with a release agent along the length direction of the cast roll to the surface of the cast roll within 5 seconds before the initial casting, and the side of the cast roll is provided with a device for spraying the release agent spray device. The spray concentration of the release agent is 12ppm.

[0021] (2) Extrude the film-making stock solution at 82°C onto a casting roll to cast a film, the temperature of the casting roll is 72°C, the optical film is continuously peeled off from the casting roll, and the casting roll rotates The linear speed is 10m / min.

[0022] After the optical film is peeled off, the 1-2m length of the front end of the film is cut off, and then the subsequent drying and heat treatment process is introduced.

[0023] Casting rolls are used to cast the film. The water co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com