Continuous distillation and extraction device

An extraction device and distillation tube technology, applied in the field of extraction devices, can solve the problems of low extraction efficiency, high-temperature pyrolysis, oxidation, etc., and achieve the effects of convenient operation, reduced water vapor backflow, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention takes dichloromethane as the extract phase / heavy phase and water as the light phase as an example, and further describes the present invention.

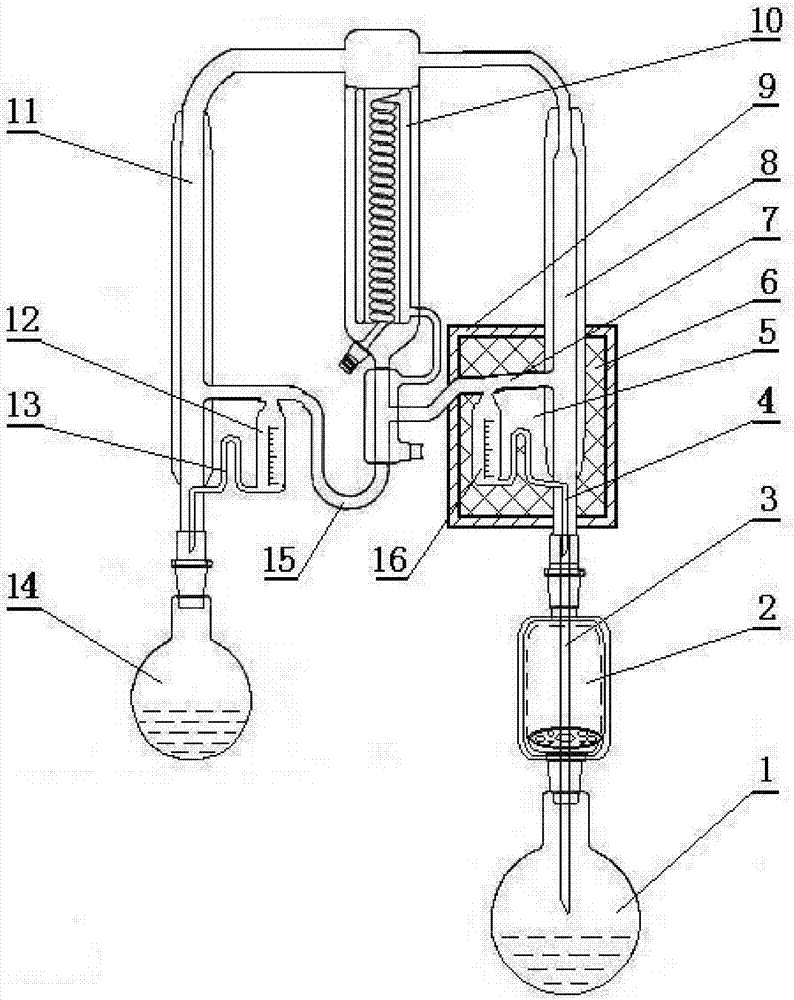

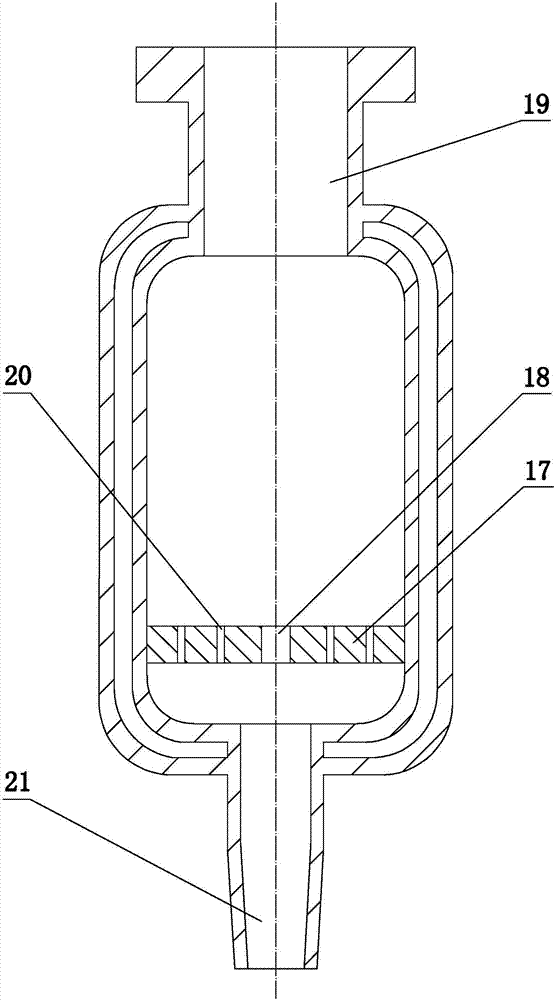

[0019] Such as figure 1 , figure 2 As shown, this continuous distillation extraction device that can improve the extraction rate of volatile and semi-volatile components includes an aqueous phase distillation vessel 1, an organic phase distillation vessel 14, a first distillation tube 8, a second distillation tube 11, and mixed extraction. The condensing chamber 10 and the U-shaped stratified reflux pipe 15. One end of the U-shaped stratified reflux pipe 15 passes through the second metering bottle 12 and the second siphon 13 and then connects with the second distillation pipe 11, and the U-shaped stratified reflux pipe 15 The other end passes through the first reflux tube 7 and the first siphon tube 4 in turn, and then connects with the first distillation tube 8. The first distillation tube 8 and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com