Cooling system for glass fiber cloth

A technology of glass fiber cloth and cooling system, which is applied in heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc. It can solve the problems of prolonging the production cycle of glass cloth, affecting the quality of cloth surface, affecting production efficiency, etc., and shortening production Cycle, improve production efficiency, improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

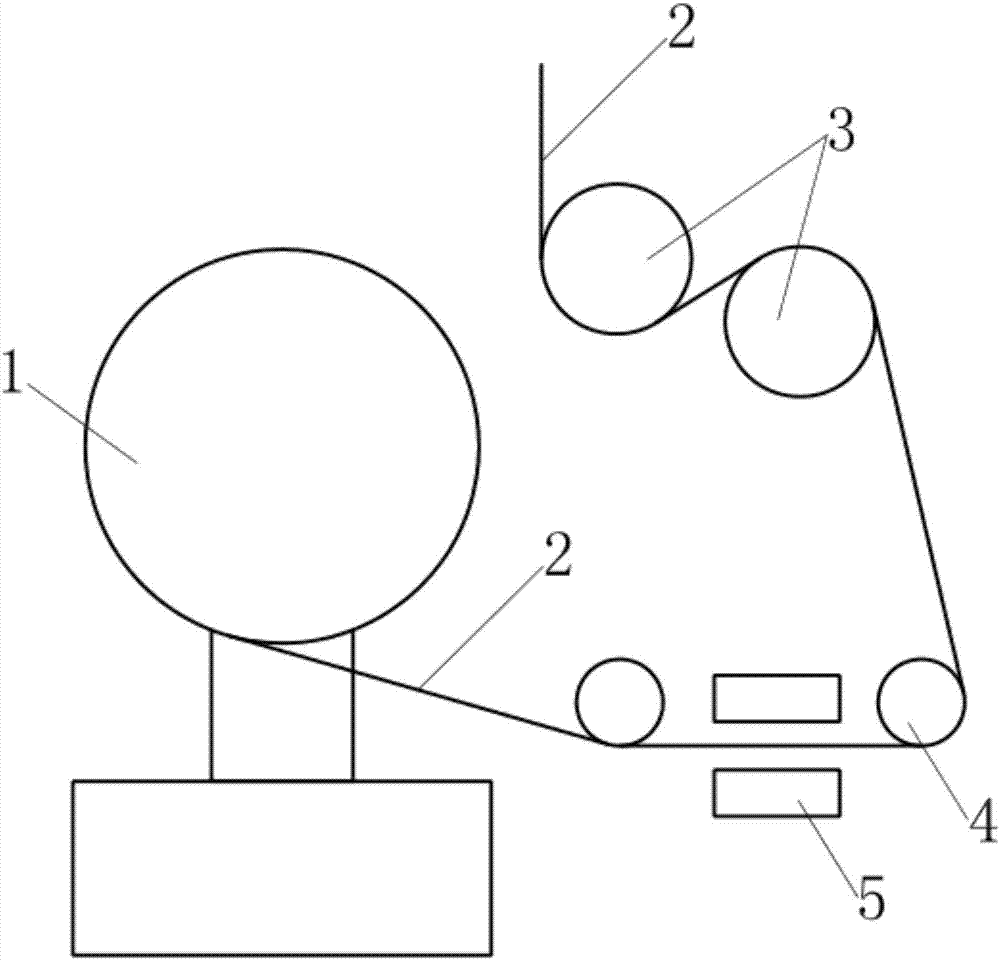

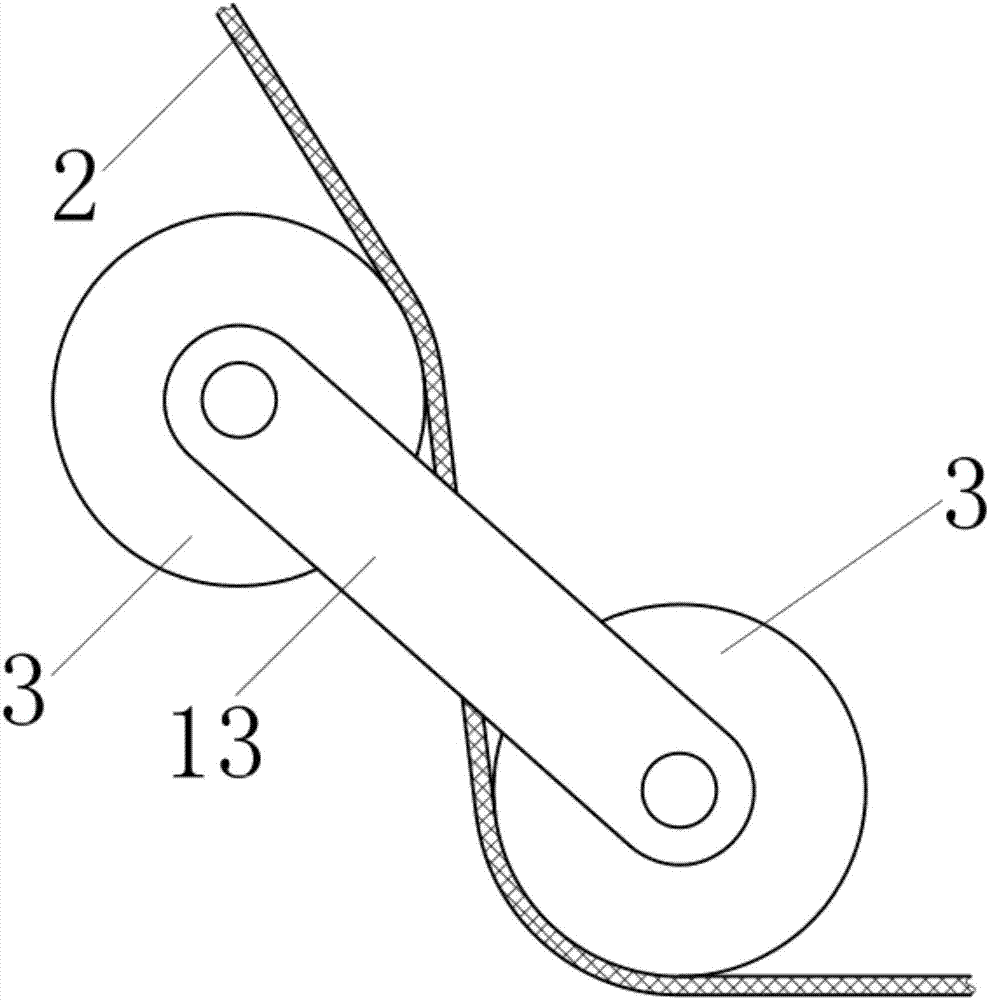

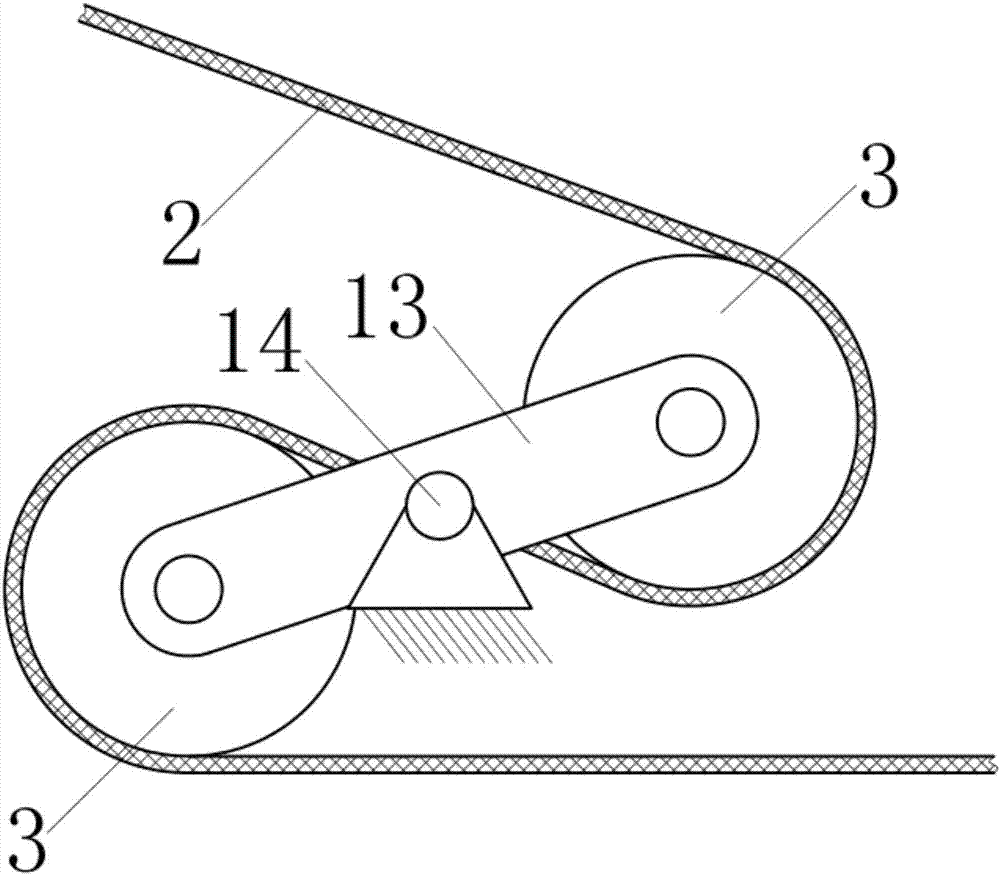

[0037] In order to achieve the purpose of the present invention, figure 1 A schematic structural view of an embodiment of the present invention is shown. The conveying roller 1 conveys the glass fiber cloth 2 to be cooled; the guide roller 4 and the cloth catcher 5 guide the glass fiber cloth 2 to be cooled to the cooling roller 3; there are at least two cooling rollers 3, and the cooling roller The cylinder 3 is in contact with the front and back surfaces of the glass fiber cloth 2 respectively, and the inside of the cooling roller 3 is equipped with a cooling medium that exchanges heat with the glass fiber cloth 2, and the cooling roller 3 has a cycle that brings the cooling medium into and out of the cooling roller 3 pipeline.

[0038] The beneficial effect of adopting the above technical solution is: the glass fiber cloth does not need to wait for its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com