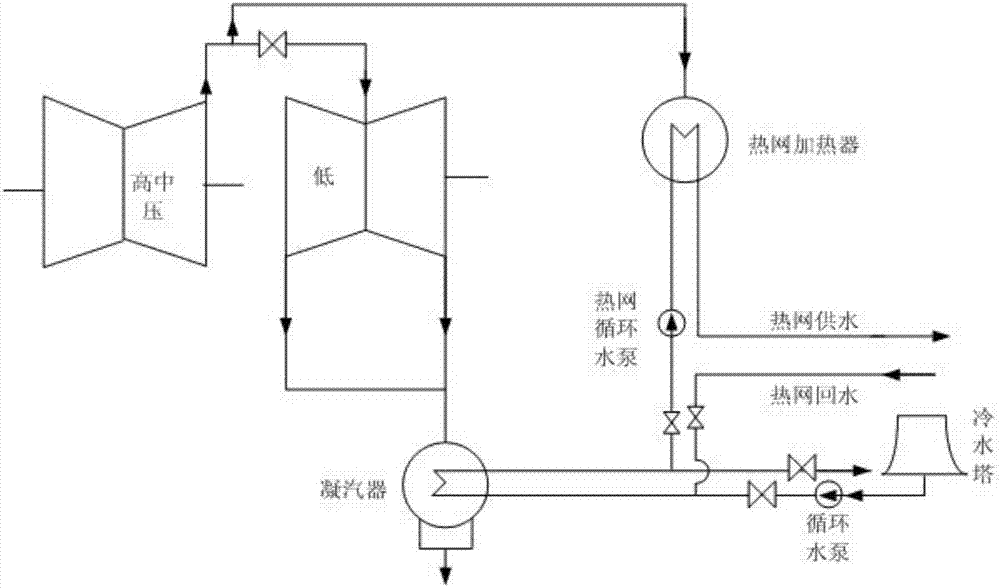

Heat supply system of high-back-pressure double-rotor electric heating unit

A heating system, high back pressure technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve problems such as energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

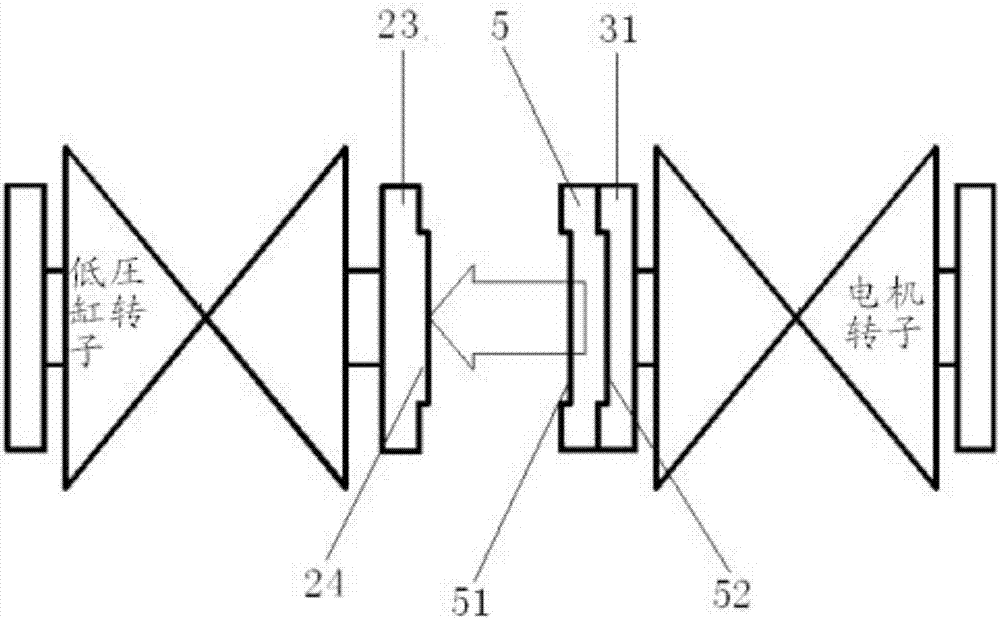

[0029] In the heating system of the high back pressure dual-rotor electric heating unit in this embodiment, on the basis of Embodiment 1, the low-pressure cylinder rotor of the steam turbine unit includes a pure condensing rotor used during non-heating period and a high back pressure rotor used during heating period , among them, the number of stages of the pure condensing rotor is 2×6, the number of stages of the high back pressure rotor is 2×4, the whole forging has no center hole, and the high back pressure rotor has two impellers less than the pure condensing rotor; the pure condensing rotor and the high The half-couplings at both ends of the back pressure rotor are centered and the accuracy of the bolt holes of the two half-couplings is consistent.

[0030] Furthermore, the replacement structure of the pure condensate rotor and the high back pressure rotor: hydraulic expansion coupling bolts are used, and the positioning and boring accuracy of the coupling pin holes are gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com