Tailing pond online monitoring system

A monitoring system and a technology for tailings ponds, which are applied in the field of online monitoring, can solve the problems of difficulty in grasping various technical indicators of tailings ponds in a timely manner, affecting safe production and safety management of tailings ponds, and inability to monitor technical parameters of tailings ponds in real time. , to achieve the effect of improving the ability to deal with harsh working environments, improving real-time monitoring capabilities, and improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means realized by the present invention; creative features; achieve the purpose and effect easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments.

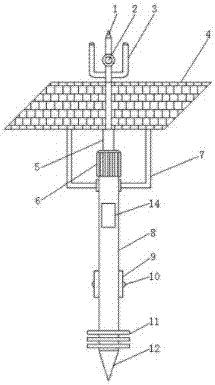

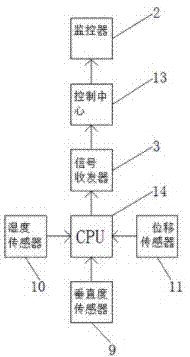

[0017] like Figure 1-2 As shown, an online monitoring system for tailings storage includes a fuselage 8, the top of the fuselage 8 is fixedly connected with a motor 6 by bolts, and the top of the motor 6 is rotatably connected with a transmission shaft 5, and the transmission shaft 5 A lightning arrester 1 is fixedly connected to the top of the lightning arrester 1, a monitor 2 is sleeved in the middle of the lightning arrester 1, a signal transceiver 3 is welded on both sides of the middle of the lightning arrester 1, and a signal transceiver 3 is welded on both sides of the middle of the lightning arrester 1, and the two sides of the top of the fuselage 8 are fixedly connected by bolts. A bracket 7, the top of the bracket 7 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com