Electromagnetic acoustic transducer

An acoustic sensor, electromagnetic technology, applied in scientific instruments, instruments, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as safety and infeasibility, and achieve the effect of simplifying layout and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

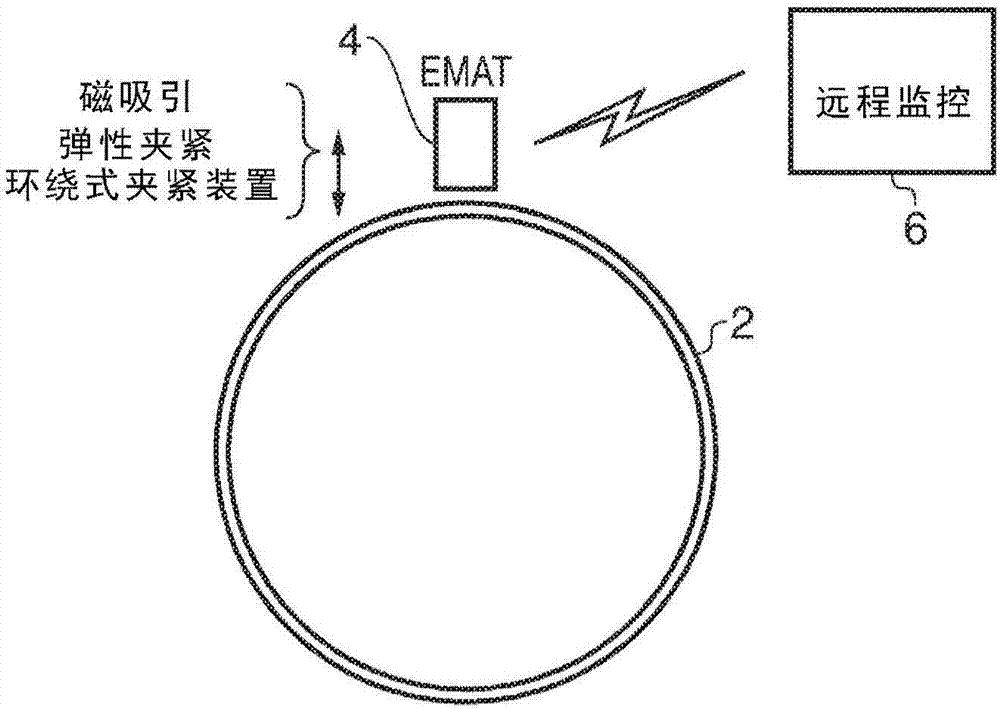

[0052] figure 1 An exemplary detection object 2 in the form of a steel pipe is schematically shown, the electromagnetic-acoustic sensor 4 is magnetically attracted to, elastically clamped to the curved surface of the pipe 2 and / or a surrounding clamping device (which passes around the pipe 2) One or more of them are held to the surface of the pipeline 2, and the detection object will be subjected to internal erosion monitoring, defect detection, etc. using the electromagnetic acoustic sensor 4. The sensor 4 is battery driven (may also use mains power or energy harvesting devices) and communicates wirelessly with a remote monitoring system 6 that receives and interprets the ultrasonic inspections of the pipeline 2 periodically performed by the sensor 4 . Pipe 2 may have a non-conductive coating to inhibit external corrosion. For example, the pipe 2 can be coated with such a coating. Despite this non-conductive coating, the electromagnetic-acoustic sensor 4 is able to excite a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com