Control system and control method for diameter of single crystal ingot

一种控制系统、单晶锭的技术,应用在单晶生长、单晶生长、化学仪器和方法等方向,能够解决单晶可用面积减少、摇晃、直径偏差等问题,达到防止不均匀生长、防止摇晃、减小直径偏差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, various embodiments will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to these embodiments. In describing the embodiments of the present invention, detailed descriptions of known functions or configurations may be omitted to make the gist of the present invention clearer.

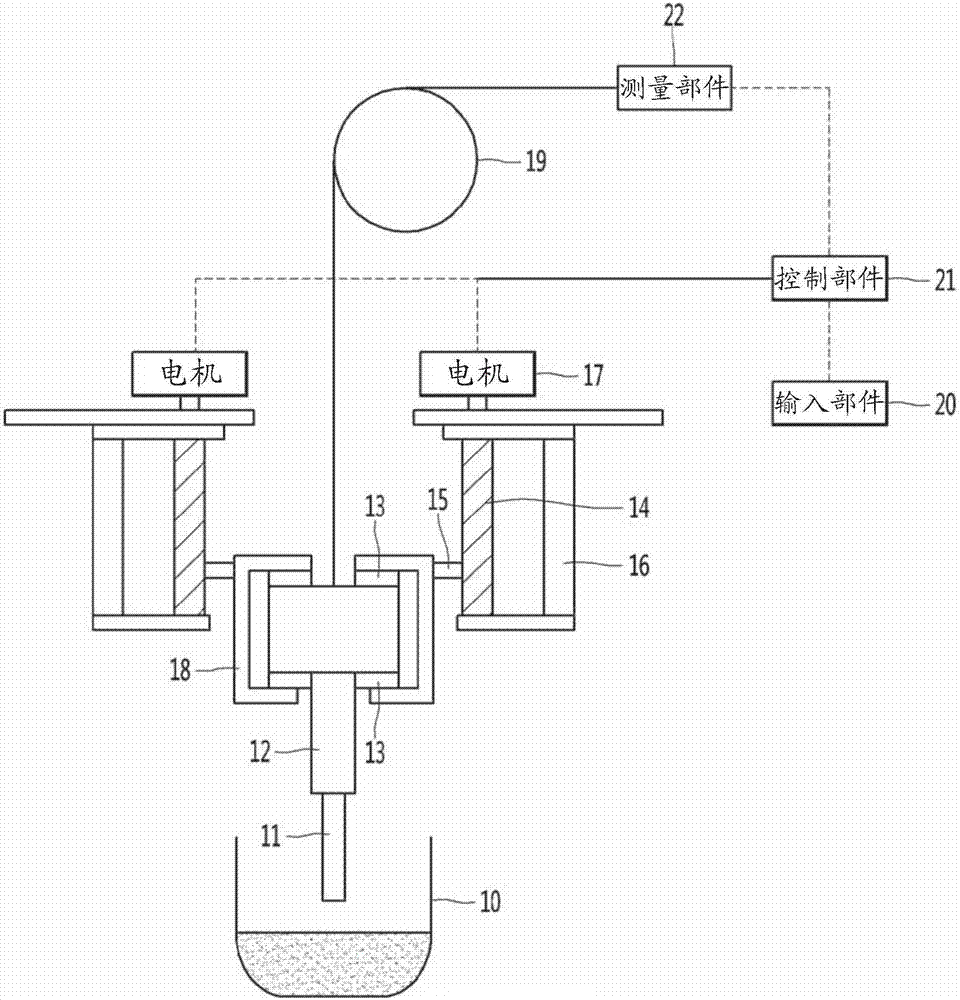

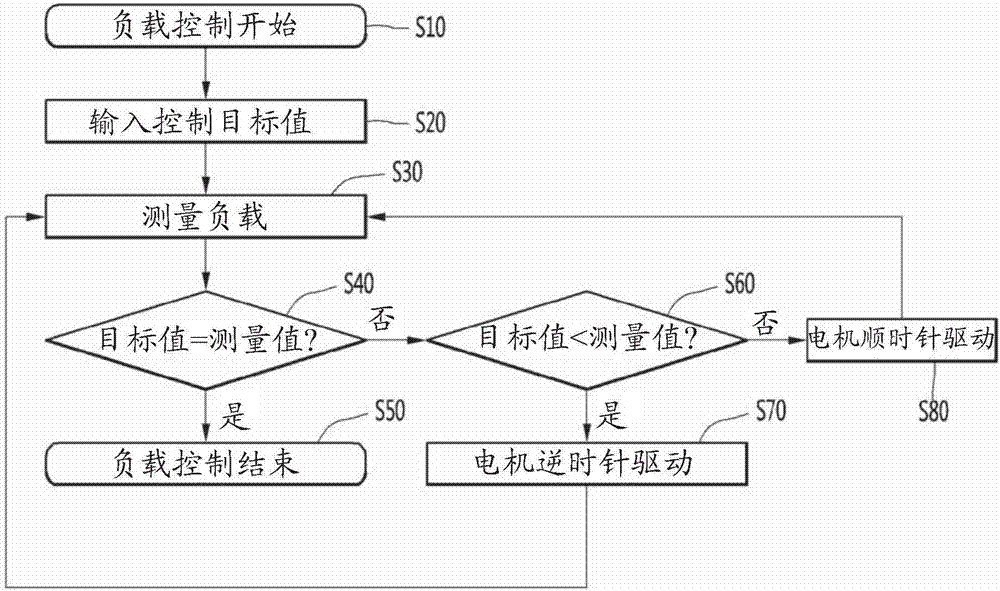

[0031] The present invention provides: a single crystal growth apparatus according to an embodiment of the present invention as a device capable of growing a single crystal ingot by applying an additional load to a seed chuck connected to a seed crystal from the initial growth process of the single crystal ingot and a method of controlling growth conditions while the seed crystal is not shaken due to increasing the weight of the growing single crystal ingot to a certain extent.

[0032] figure 2 is a sectional view showing a single crystal ingot growing apparatus according to the present invention. refer to figure...

PUM

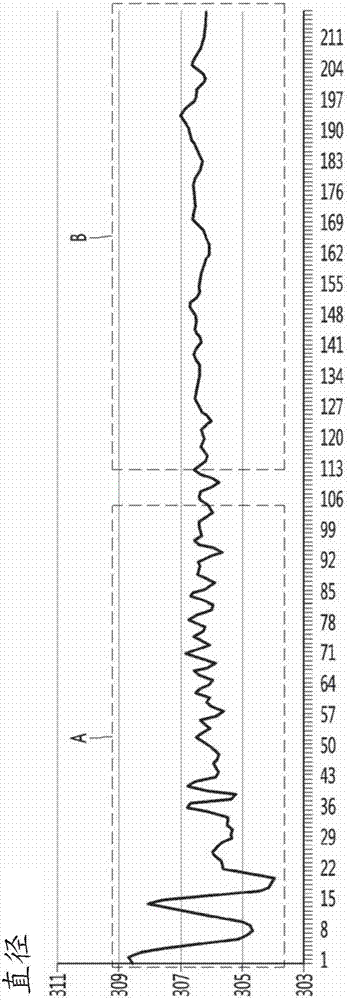

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com