Disk type laser cleaning machine

A laser cleaning and turntable technology, which is applied to dryers, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as waste of water resources, environmental pollution, secondary pollution, etc., to reduce labor costs and improve Cleaning efficiency, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

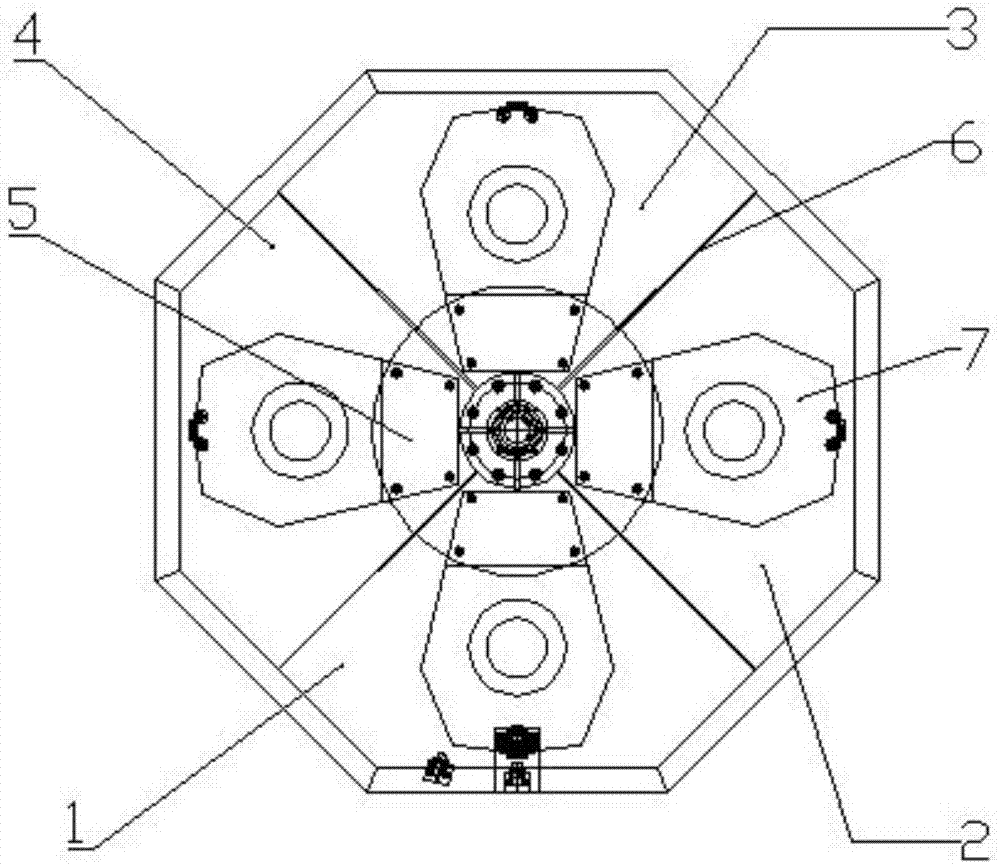

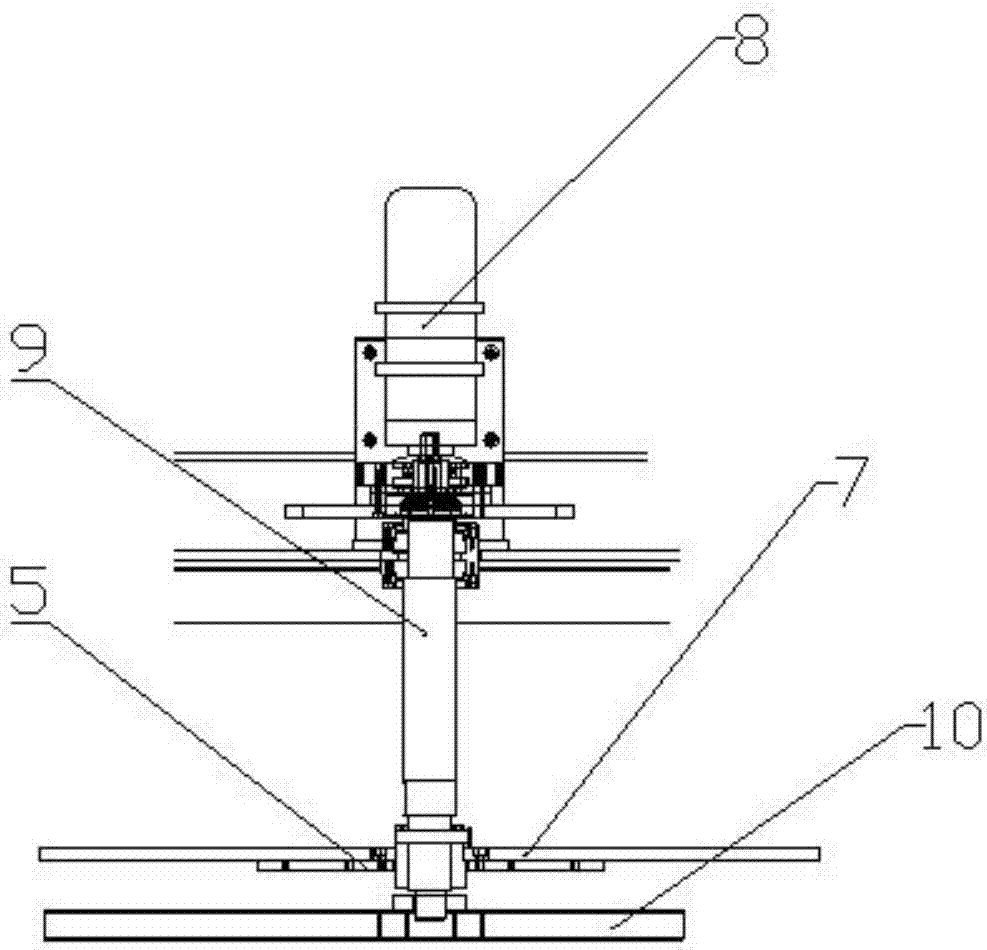

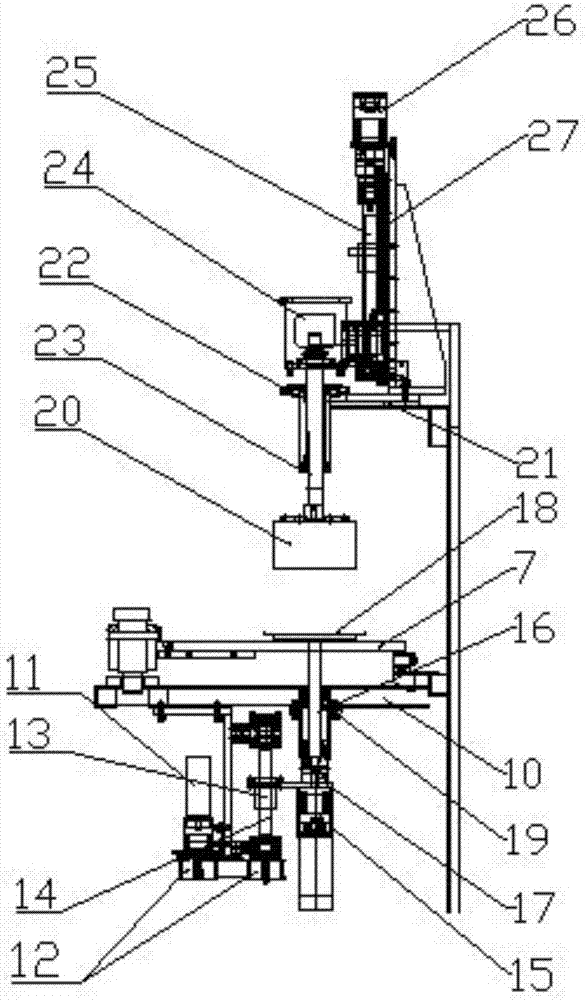

[0026] Example: structure of a turntable laser cleaning machine

[0027] combine figure 1 with figure 2 , a turntable type laser cleaning machine, including a device frame 10, a turntable rotation mechanism, an operating station and a partition mechanism, the turntable rotation mechanism includes a main drive shaft 9 arranged on the top, a first drive for driving the main drive shaft to rotate Motor and speed reducer 8, turntable fixed plate 5, described turntable fixed plate 5 is connected with main transmission shaft 9, first drive motor and speed reducer 8 drive main transmission shaft 9 to rotate, thus turntable fixed plate 5 also follows the main transmission shaft Rotate; the baffle mechanism includes a baffle 6 and a baffle drive motor that drives the baffle to lift and descend; the operating station is arranged on the turntable 7 fixed on the turntable fixed plate 5, and the operating station includes manual up and down Material station 1, laser cleaning station 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com