Method for preparing high-dielectric low-loss copper titanate calcium-based ceramic with core-shell structure

A technology of copper calcium titanate and shell structure, which is applied in the field of high-dielectric and low-loss copper calcium titanate-based ceramics, can solve the problem of low-frequency dielectric constant reduction and achieve the effect of reducing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

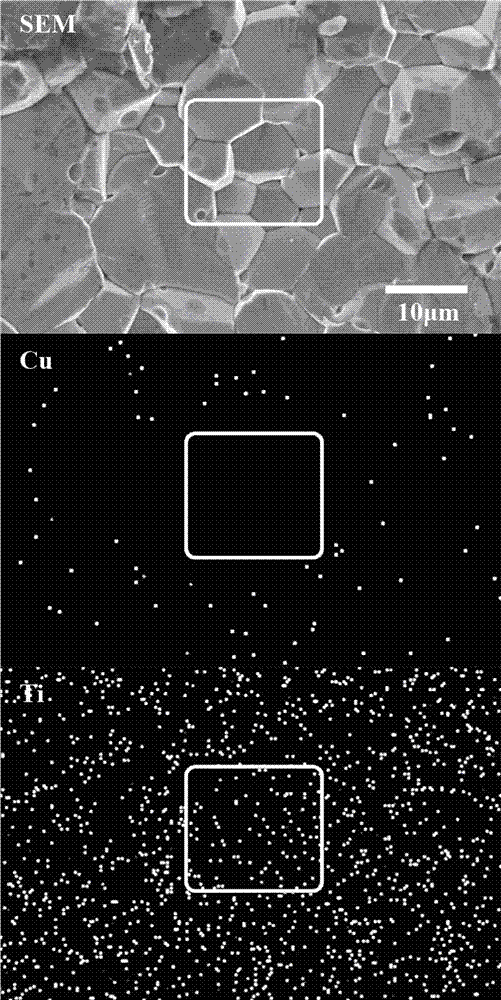

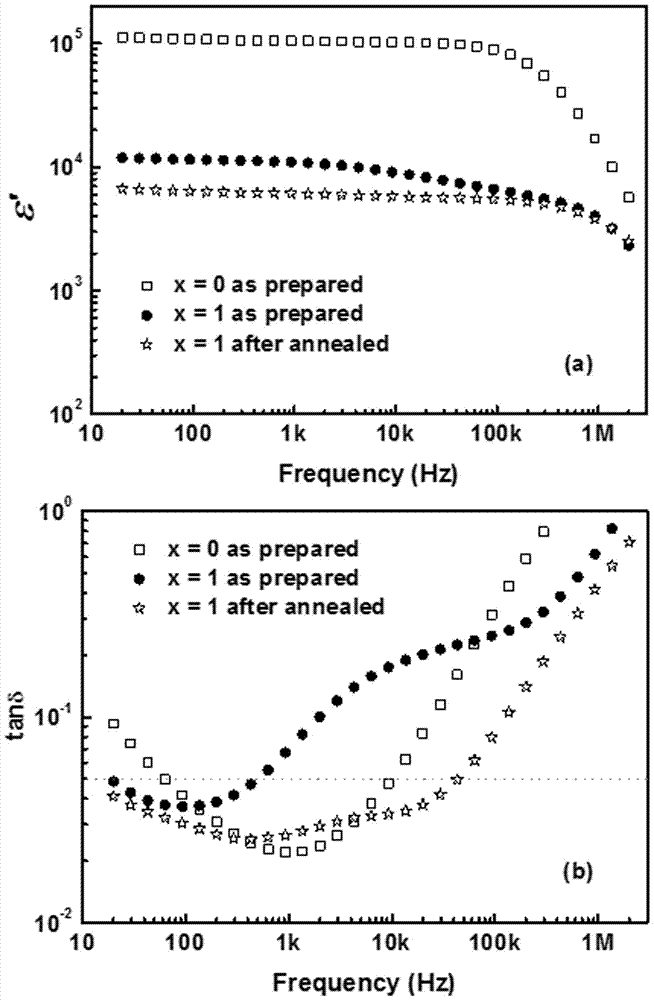

[0014] To analyze pure calcium nitrate (Ca(NO 3 ) 2 • 4H 2 O, 99%), copper nitrate (Cu(NO 3 ) 2 •3H 2 O, 99%) and tetrabutyl titanate ([CH 3 (CH 2 ) 3 O] 4 Ti, 99%) as the initial raw material, adding citric acid (C 6 h 8 o 7 , 99%), the CCTO powder was prepared by the sol-gel method, first according to the CaCu 3 Ti 4 o 12 The stoichiometric ratio of various raw materials is accurately weighed, then dissolved in ethanol and mixed evenly, and the pH of the solution is only adjusted to 2~3 with nitric acid. After the solution was stirred by magnetic force, it was placed in a constant temperature of 80°C and incubated for 6 hours to make the solution form a colloid, and then kept in a constant temperature of 100°C for 2 hours to become a xerogel. The dry gel was calcined in the atmosphere at 750°C for 2 hours to obtain the CCTO precursor powder. Followed by CCTO / xTiO 2 (x=0, 0.5, 1 and 2) stoichiometric ratio Accurately weigh CCTO powder, tetrabutyl titanate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com