Low-refractive-index and high-transparency TPU film and preparation method thereof

A low-refractive-index, thin-film technology, applied in the field of low-refractive-index and high-transparency TPU films and their preparation, can solve the problems of weakened mechanical properties, decreased transparency, yellowing, etc., and achieves the effects of high transparency and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of low refractive index high transparent TPU film, adopts following method to prepare:

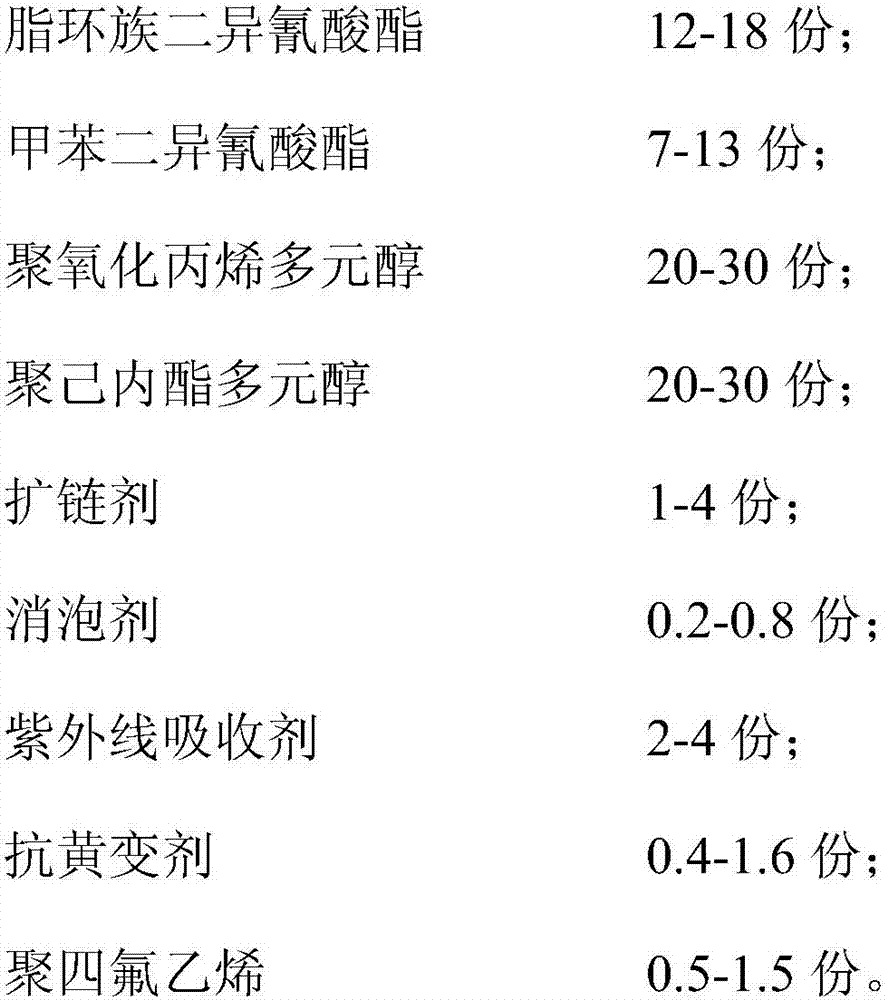

[0038] 1) Raw material and ratio:

[0039]

[0040] 2) Preparation method:

[0041] ① Dry the components at 90°C for 8 hours according to the formula, and then mix them;

[0042] ②The mixed components are extruded through the extruder. The temperature of the solid conveying zone of the extruder is 260°C, the temperature of the material plasticizing zone is 180°C, and the temperature of the melt conveying zone is 320°C.

Embodiment 2

[0044] A kind of low refractive index high transparent TPU film, adopts following method to prepare:

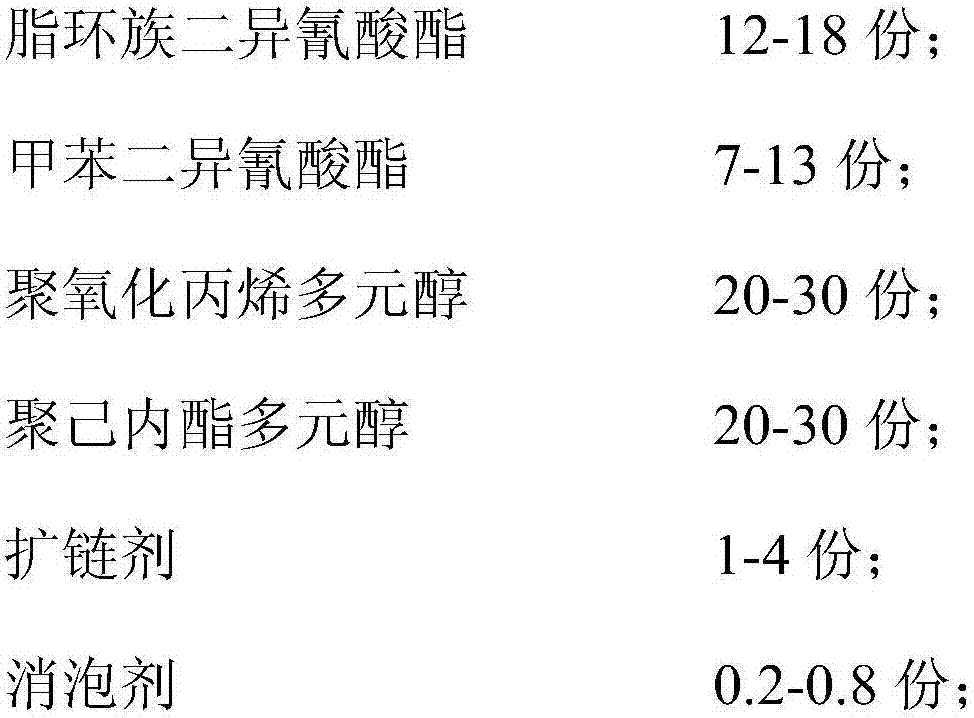

[0045] 1) Raw material and ratio:

[0046]

[0047] 2) Preparation method:

[0048] ① Dry the components at 110°C for 4 hours according to the formula, and then mix them;

[0049] ②The mixed components are extruded through the extruder. The temperature of the solid conveying zone of the extruder is 440°C, the temperature of the material plasticizing zone is 860°C, and the temperature of the melt conveying zone is 420°C.

Embodiment 3

[0051] A kind of low refractive index high transparent TPU film, adopts following method to prepare:

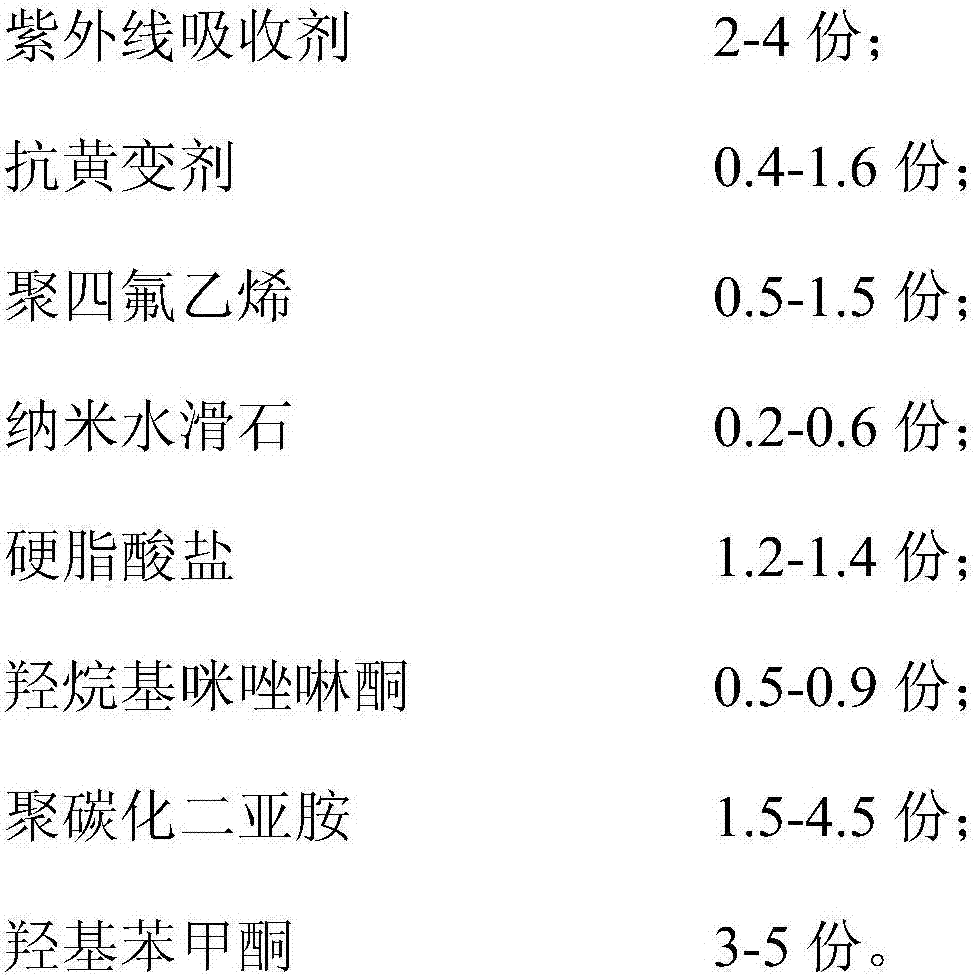

[0052] 1) Raw material and ratio:

[0053]

[0054]

[0055] 2) Preparation method:

[0056] ① Dry the components at 100°C for 6 hours according to the formula, and then mix them;

[0057] ②The mixed components are extruded through the extruder. The temperature of the solid conveying zone of the extruder is 350°C, the temperature of the material plasticizing zone is 520°C, and the temperature of the melt conveying zone is 370°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com