A kind of anti-perspiration firm enhancer and its preparation method and application

A technology of perspiration resistance and lifting agent, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of unsuitable fur dyeing post-treatment, affecting the quality of leather boards, high post-processing temperature, etc., and achieves convenient application and easy operation , the effect of mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

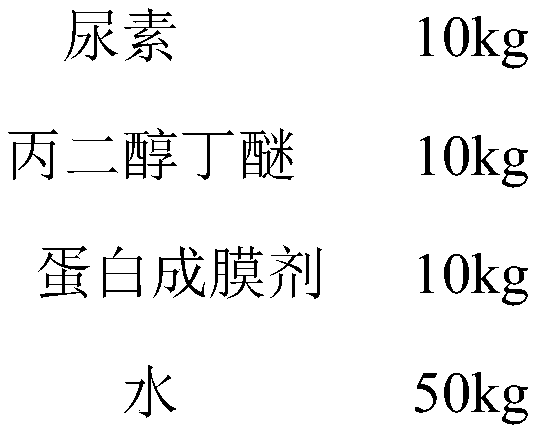

[0036] The raw materials of the perspiration-resistant firm enhancer are proportioned as follows:

[0037]

[0038] The preparation method is as follows:

[0039] 1) Put urea and water in the reactor, heat and stir, control the temperature at 25-30°C, stop heating after it is completely dissolved, and continue stirring for 15-30min;

[0040] 2) After the temperature in the reactor drops to 15-20°C, add the protein film-forming agent and propylene glycol butyl ether into the reactor, and continue stirring for 30-60 minutes to obtain the product.

Embodiment 2

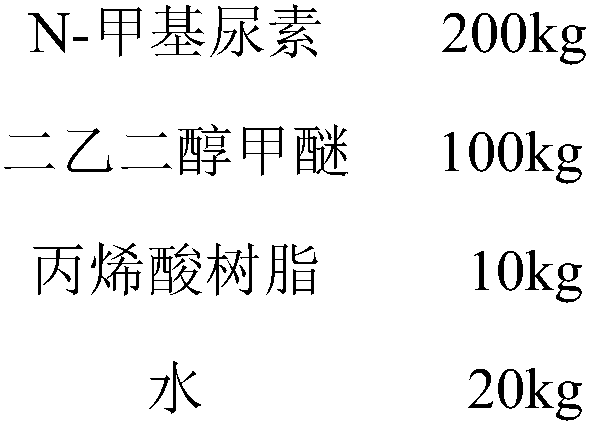

[0042] The raw materials of the perspiration-resistant firm enhancer are proportioned as follows:

[0043]

[0044] The preparation method is as follows:

[0045] 1) Put N-methylurea and water in the reactor, heat and stir at 300-400rpm, control the temperature at 25-30°C, stop heating after it is completely dissolved, and continue stirring for 20min;

[0046] 2) After the temperature in the reactor drops to 15-20°C, add acrylic resin and diethylene glycol methyl ether into the reactor, and continue stirring for 40 minutes to obtain the product.

Embodiment 3

[0048] The raw materials of the perspiration-resistant firm enhancer are proportioned as follows:

[0049]

[0050]

[0051] Subsequent preparation method is consistent with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com