Self-driven expansion generator system

A generator and self-driven technology, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of insufficient power generation efficiency and unstable unit system, so as to improve power generation efficiency and system reliability, reduce demand, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

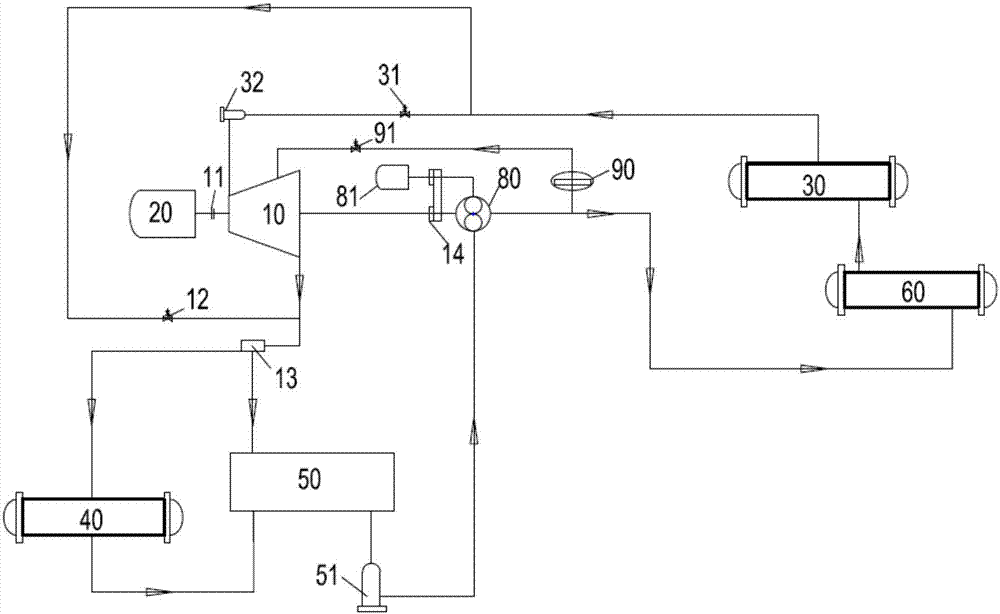

Embodiment 1

[0026] Embodiment 1: as figure 1As shown, in this embodiment, the starting device is a working medium pump motor. The starting steam drum 90 evaporates the organic working medium in it into gas and then enters the expander 10 through the bypass valve 91 to provide air bearings for the expander. Gas buoyancy, after the bearing runs normally, the working medium pump motor 81 drives the working medium pump 80 to run, and the working medium pump 80 pumps the liquid working medium in the liquid reservoir into the preheater 60 for preheating, and the liquid working medium in the liquid storage and the working medium The liquid filter 51 installed between the mass pumps is used to filter impurities in the liquid working medium. The preheated liquid working medium enters the evaporator and is heated by an external low-grade heat source to become high-temperature steam, and then passes through the intake valve 31 And the gas path filter 32 enters the expander 10 to expand, the flywheel...

Embodiment 2

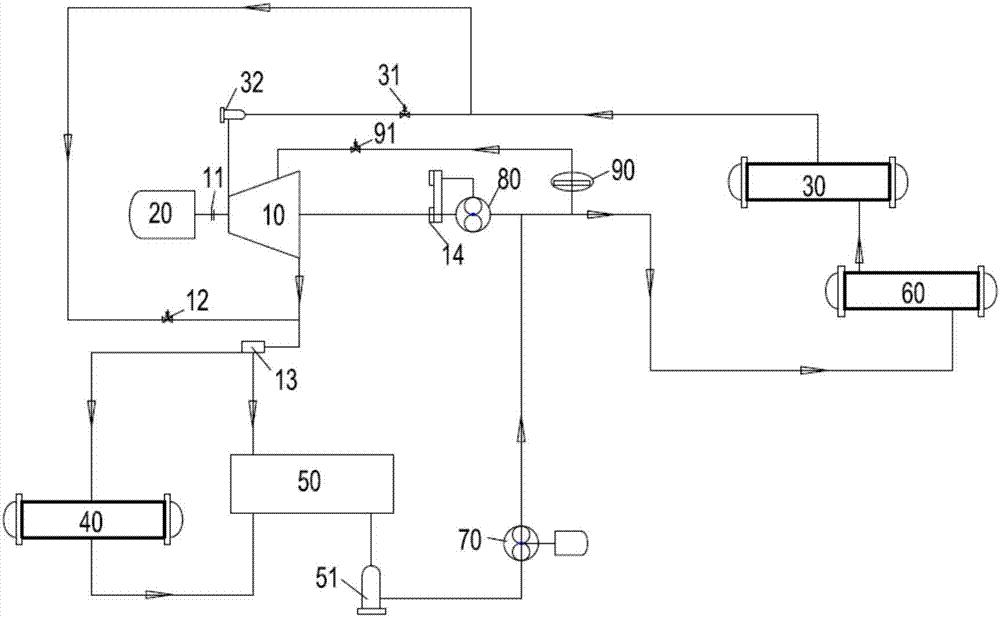

[0027] Embodiment 2: as figure 2 As shown, in this embodiment, the starting device is a working medium starting pump, and the clutch 14 and the working medium pump 80 are in a disengaged state at the beginning, and the starting steam drum 90 evaporates the organic working medium in it into a gas and then passes through the bypass valve 91 Enter the expander 10 to provide gas buoyancy for the air bearing of the expander. After the bearing operates normally, the working fluid starting pump 70 pumps the liquid working medium in the liquid storage into the preheater 60 for preheating. The liquid filter 51 installed between the device and the working medium pump is used to filter impurities in the liquid working medium. The preheated liquid working medium enters the evaporator and is heated by an external low-grade heat source into high-temperature steam and then passes through the evaporator. The air valve 31 and air filter 32 enter the expander 10 for expansion. After the expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com