Method for converting pixel data of tooth CT image into 3D printing data

A CT image and 3D printing technology, applied in the field of image processing, can solve the problems of not providing a 3D printing data output interface and a low degree of self-adaptation, and achieve the effect of improving image conversion efficiency and precision, high degree of self-adaptation, and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figure 1-2 As shown, a method for converting tooth CT image pixel data to 3D printing data includes the following steps:

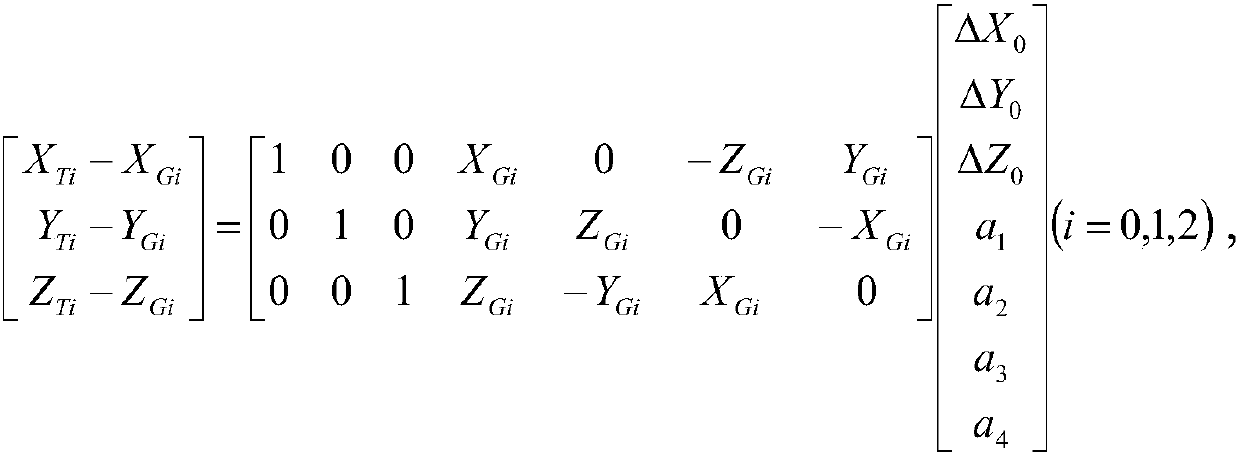

[0032] S1: Use CT equipment to scan teeth to obtain CT images, use edge-preserving filtering algorithms to suppress noise, and analyze the blur scale and structure scale of CT images to achieve scale-adaptive contour extraction, ensuring that the algorithm is suitable for CT with inconsistent contrast and inconsistent ambiguity For the effectiveness of image processing, when extracting image pixel data, coarse positioning is first used to determine the edge pixel data and pixel-level position coordinates of the CT image to ensure the reliability of the edge. At the same time, by reducing the number of candidate points to be processed in sub-pixel positioning, To reduce the amount of calculation, for the extracted edge pixel data, through post-processing techniques such as edge enhancement, edge connection and edge refinement, the closed pix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com