Direct torque control method for high load capability of dual-three phase permanent magnet synchronous motor

A technology of direct torque control and dual-three-phase permanent magnets, which is applied in motor generator control, electronically commutated motor control, control systems, etc., and can solve the problems of reduced output torque capacity of the drive system and reduced motor load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

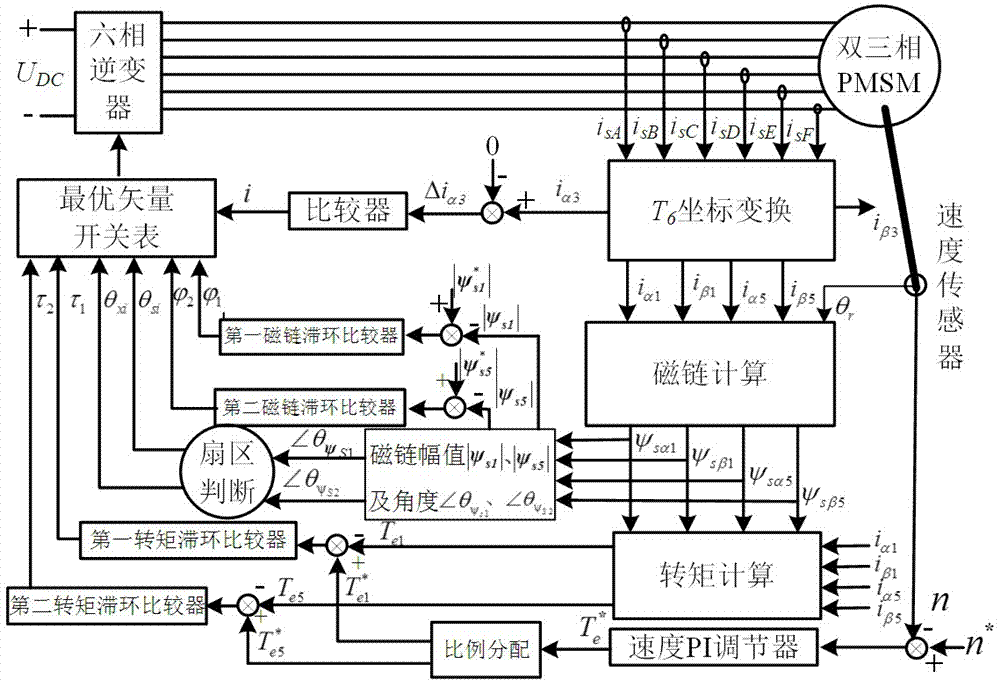

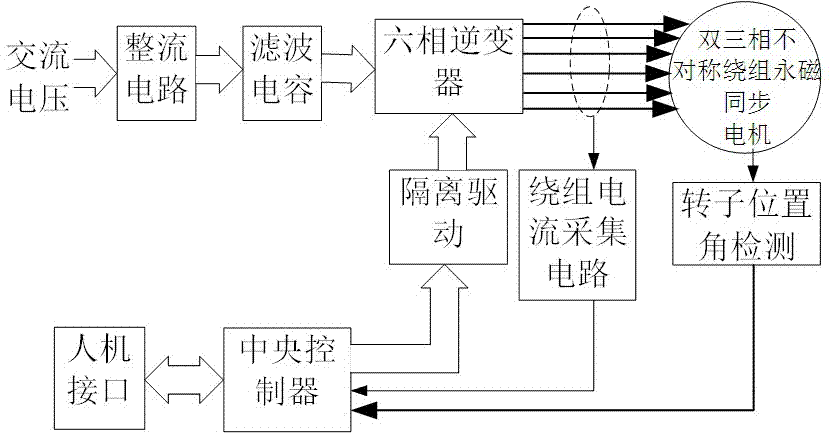

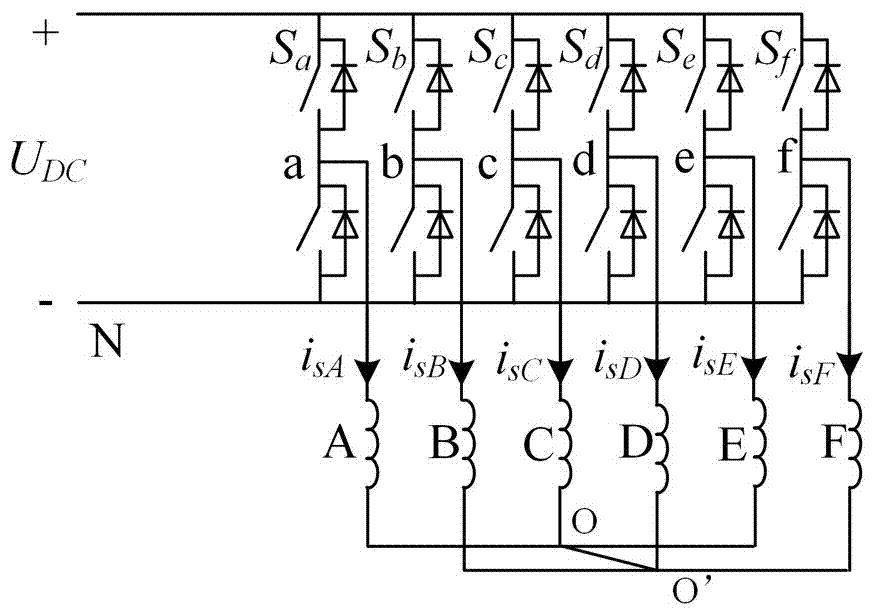

[0074] like figure 1 As shown, a direct torque control method for high load capacity of a dual-three-phase permanent magnet synchronous motor includes the following steps: Step S1: The motor has two three-phase windings, which are respectively ACE windings and BDF windings, and each three-phase winding The three phases are 120 degrees electrical angle different from each other, and the two sets of three-phase windings are offset by 30 degrees electrical angle. The two sets of three-phase windings each have a center point O point and O' point, and the center point O-O' of the two windings Connect, use the orthogonal transformation matrix T6 to convert the six-phase input current i of the motor sA ~i sF transform to alpha 1 beta 1 -α 5 beta 5 -α 3 beta 3 In the stationary coordinate system, the fundamental wave current i is obtained α1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com